Selling a cost effective digital dial indicator which has an absolute/incremental reading with a range of 0-4" (0-100mm). The sisco digital micrometer has a highly sensitive glass sensor for fast and accurate measurements.

Extra large screen with clear display

- The digital dial indicator has a large screen that displays the measured values in digital form.

- The digital dial indicator is equipped with a data output for easy transfer of measurement data to a computer or other device.

- The digital dial indicator features a highly sensitive glass sensor for fast and accurate measurements.

- Digimatic indicator with absolute and relative measurement modes.

- Digital dial gauge housing is made of space-aluminium ceramic oxide technology and is durable and scratch-resistant.

- Digital indicators can be converted from metric to imperial in any position.

Application

Digital dial indicators are commonly used in the manufacturing industry for precision measurement tasks such as quality control, machine setup, and alignment. They are also used in the automotive industry for measuring engine components, brake rotors, and tire tread depth. Additionally, absolute digimatic indicators are useful in the field of engineering for measuring the deflection or deformation of materials under load.

- Model: SISCO-SI-G3100

- Range: 0-4 inch (0-100 mm)

- Resolution: 0.0005 inch (0.01mm)

- Accuracy: ±0.02mm

- Repeatability: 0.01mm

- Sensor: Glass grid displacement sensor

- Display: LCD

- Response Speed: 1.5m/s

- Sleeve Diameter: Metric (ISO/GB): 8mm, Imperial (ANSI): 3/8 inch

- Measuring Rod Movement Speed: 1.5m/S

- Measuring Head: M2.5X0.45 threaded carbide

- Operating Temperature: 0-40°C

- Storage Temperature: -109C-60°C

- Battery: 3V CR2032 button cell: 2000 working hours, 0-5mm Battery: 3V CR1632 button cell

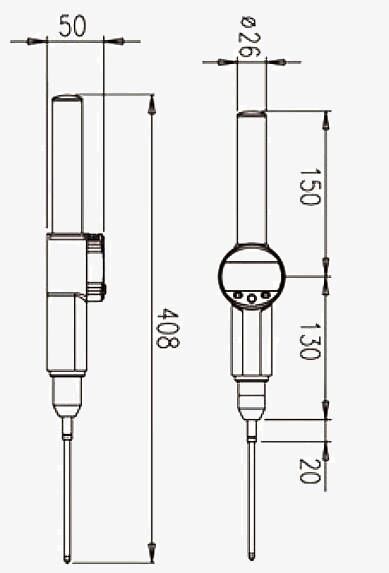

Dimension: (Unit: mm)

Q1: What is a digital dial indicator?

A1: A digital dial indicator is a precision measuring tool that is used to measure the distance or movement of an object with a high level of accuracy. It is a modern version of the traditional dial indicator that features an electronic display for easy and accurate reading.

Q2: How do I use a digital dial indicator?

A2: To use a digital dial indicator, first attach the probe to the object you want to measure. Then, turn on the device and zero the display by pressing the "zero" button. Finally, take your measurement by moving the object and observing the display.

Q3: How accurate is a digital dial indicator?

A3: The accuracy of a digital dial indicator can vary depending on the model and manufacturer. However, most modern digital dial indicators are designed to provide accuracy within 0.001 inches or 0.02 millimeters. It is important to calibrate the device regularly to ensure the highest level of accuracy.

Tips: Do I need to calibrate my digital dial indicator?

Yes, it's important to calibrate your digital dial indicator regularly to ensure accurate measurements.

Over time, your digital dial indicator may drift from its original calibration due to wear and tear or exposure to harsh conditions. This can result in inaccurate readings that can affect the quality of your work or even lead to safety hazards.

To calibrate your digital dial indicator, you can use gauge blocks or a calibration machine to verify the accuracy of your instrument. This process involves comparing the readings of your dial indicator against a known standard and making adjustments if necessary.

It's recommended to calibrate your digital dial indicator at least once a year or more frequently if you use it frequently or in demanding conditions. Additionally, you should always follow the manufacturer's guidelines for maintenance and calibration to ensure optimal performance and accuracy.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.