Clamp type current transformer for sale, clamp jaw 14mm, accuracy 0.01mA, range 0.00mA ~ 30A AC, the sensor range, ratio, and output interface can be customized. The clip-on AC transformer is a high-precision instrumentation auxiliary device essential for detecting, monitoring, and discriminating power signal output.

Clamp-on current transformer makes field testing easy

- Non-contact measurement, easy, fast, and safe operation.

- Thin jaws, suitable for small spaces.

- The sisco clamp current transformer uses a permalloy core for stable performance and high accuracy, and is highly resistant to interference, making it suitable for complex interference environments.

- The range, ratio, and output interface of the sensor can be customized according to customer requirements.

- Output connector: φ3.5mm audio plug/BNC plug/4.0mm double banana plug (optional), cable length 2m.

Application

High-precision clip-on current transformers is an indispensable accessories for small, medium, and large electronic companies. The sisco clamp-on current transformer is suitable for use in power equipment testing, communications and telecommunications, railway and oilfield monitoring, building and construction companies, research and teaching units, industrial and mining records, and other fields.

| Model | SISCO-ETCR008 |

| Measurement Range | AC 0.00mA to 30A |

| Resolution | AC 0.01mA |

| Accuracy Class | 1.0%FS (50Hz/60Hz; 23°C±2°C) |

| Turn Ratio | 2500:1 |

| Phase Error | ≤2°(50Hz/60Hz; 23°C±2°C) |

| Reference Load | RL:0~300mA≤300Ω;0~10A≤10Ω;0~100A≤1Ω |

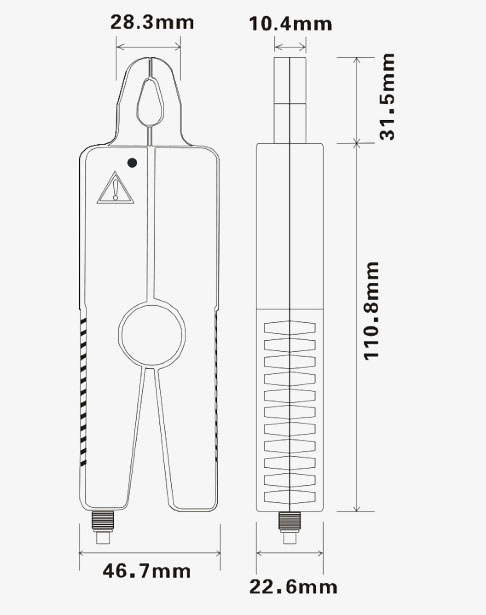

| Dimension | 137mm (L)×40mm (W)×19.5mm (H) |

| Jaw Size | φ14mm |

| Detection Method | Clamp CT |

| Output Method | Current Sensing Output |

| Output Interface | φ3.5mm audio plug / BNC plug / 4.0mm double banana plug (optional) |

| Output Wire | 2 Core shielded wire, wire length 2m |

| Current Frequency | 45Hz~60Hz (measured current frequency) |

| Frequency Characteristics | 10Hz to 100kHz |

| Wire Position | The wire under test is in the centre of the jaws |

| Line Voltage | Line testing up to AC 600V |

| Operating Temperature and Humidity | -20°C to 50°C, below 80% rh |

| Storage Temperature and Humidity | -10℃~60℃;less than 70%rh |

| Dielectric Strength | AC3700V/rms (between core and case) |

| Mass | 175g |

Dimension Unit (mm)

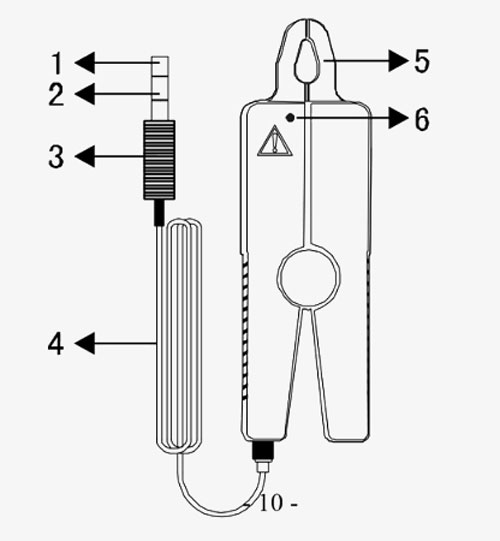

Structure

Structure

- Coil taps

- Coil taps

- Sensor output plug (φ3.5mm audio plug)

- Output lead

- Clamp head

- Directional mark identification (Identifies the same name end for phase detection)

Output interface (optional)

Q1: What is a clamp-on current transformer?

A1: Clamp-type current transformer is a kind of detection device, that can feel the information of the measured current, and can detect the felt information. Clamp AC transformers according to a certain law into a certain standard need to meet the electrical signal or other required forms of information output, in order to meet the requirements of information transmission, processing, storage, display, recording, and control. For example, switching power supply, hard switch, soft switch, etc.

Q2: What equipment can be used with a clamp-on current transformer?

A2: Clamp-on current transformers can be used with multimeters (mA level current grade), oscilloscopes, and other instruments, and clamp-on AC transformers can also be used as current probes.

Q3: What are the advantages of sisco clamp-on current transformer?

A3: sisco clamp-on current transformer is a precision current transformer, which is specially designed for power field measurement and metering use characteristics. The clamp-on current transformer is made of high permeability material, high precision, strong anti-interference ability, etc. When using the clamp-on current transformer can be directly clamped on the bus bar or bus bar without cutting off the line power outage its use is very convenient.

Tips: How does the clamp-on current transformer work with an oscilloscope?

For DC current or AC current measurements, the indirect method is generally used.

- First the flow of electricity into a proportional amount of voltage.

- Then use the oscilloscope to observe, the general test method is:

In the circuit under test in series with a high precision, resistance value of a small non-inductive resistor, and then use the oscilloscope to measure the voltage method, the voltage across the resistor measured RMS value, and then calculate the measured current value, the calculation formula is: I = U / R. The formula I measured current value A, U series resistor voltage RMS value V, R series inductance resistor resistance value Ω.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.