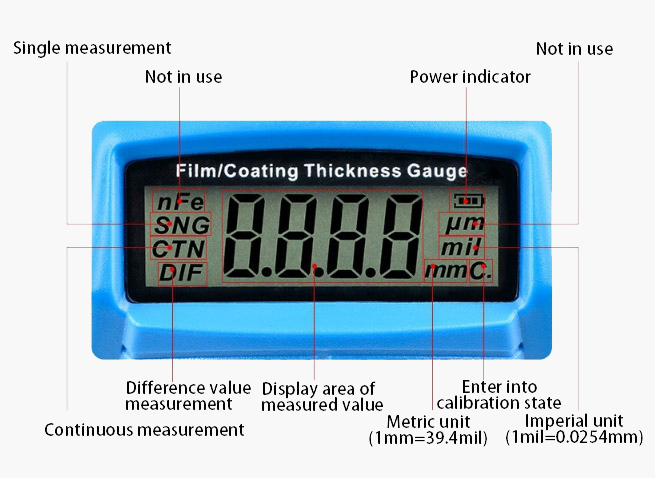

0-1800 μm paint thickness tester for sale online. The thickness gauge has a large backlit display which can read the data even in the dark area. Digital coating thickness meterwith Fe & NFe integrated probe can automatically measure iron-based surface coatings or aluminum and other non-magnetic substrates.

High-performance appearance

- Soft silicone keys for durability

- Simple and clear operation interface

HD backlight display screen design

- HD screen with backlight display

- Accurate reading even in the dark

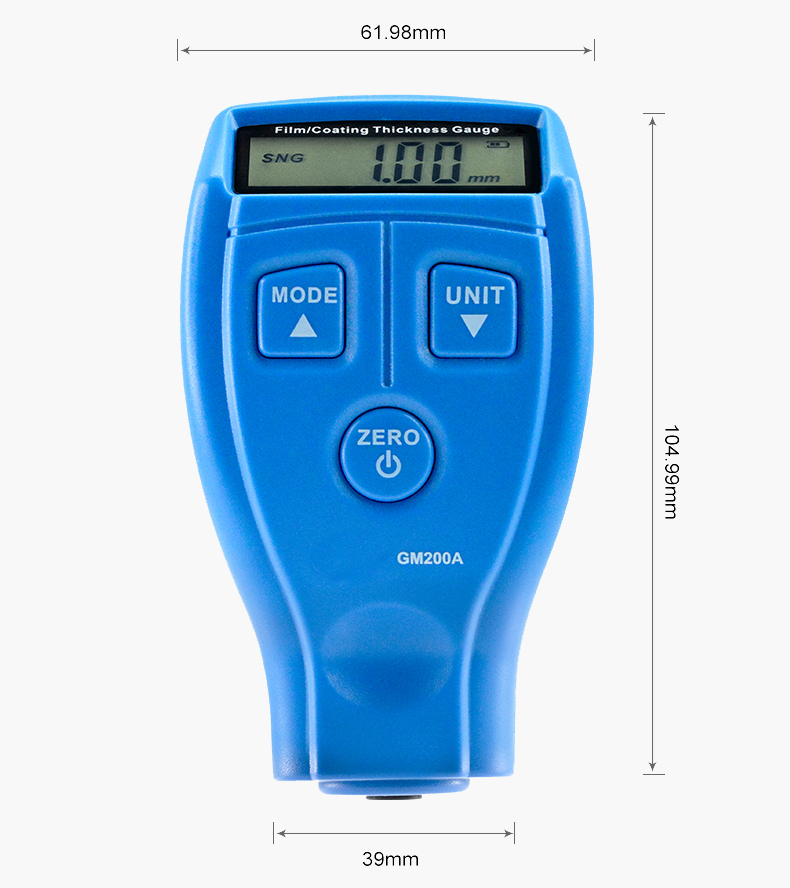

Dimension Unit (mm)

Application

The thickness measurement of the cladding is the most important process of quality inspection implemented in the metal processing industry. The coating thickness gauge perfectly handles these situations and fully enhances manufacturing efficiency, so it is widely used in metal processing, chemical industry, commercial inspection, electroplating, spraying, aluminum profiles, steel structure, etc. It is also suitable for shipbuilding, aerospace, electric power, pot special inspection, technical supervision and other industries.

| Model | SISCO-GM200A |

| Measuring Range | 0-1800μm |

| Measurement Error | ± (1+3%H) μm |

| Car Mode Resolution | 0.05mm/2mil |

| User Mode Resolution | 0.01mm/1mil |

| Minimum Diameter Of Substrate | 50mm |

| Minimum Thickness Of Substrate | 0.5mm |

| Temperature Range | 18-30℃ |

| Working Humidity Range | 10-80%RH |

| Power Supply | 2*1.5V AAA Batteries |

| Dimension | 105*31*62mm |

| Net Weight | 0.2kg |

Q1: Is laser distance meter accurate?

A1: The laser measure is accurate to within 1/8" and measures to 50 feet. It makes this measuring tool more accurate, easier and faster than a tape measure.

Q2: How do I choose a laser distance meter?

A2: Most lasers measurers are easy to fit into the palm of your hand, but some are bigger than others. If you have small hands and want a small unit that is easily controlled, or if you have big hands and need a larger laser for ease of use, check on the exact size of any model you are considering.

Q3: Do laser distance meter work outside?

A3: If you work outside, an optical scope or digital point finder is a must. Without a scope or a point finder, you can see a laser point at a maximum distance of about 30 feet on a bright day. Chances are, if you are measuring outside, 30 feet isn't going to cut it.

Tips: How to use coating thickness gauge correctly?

In the process of use, many novices do not know how to deal with the use of the digital coating thickness gauge due to improper operation.

- The digital coating thickness gauge cannot be turned on. First, check whether the battery is charged and whether the battery is in good contact. Check whether the electrode pads have been oxidized or rusted. You can replace the battery or scrape the oxide layer. If you still can't solve it, look at the button and finally look at the host line failure.

- The digital coating thickness gauge measurement is not accurate. In general, the error range follows ≦ 3% (thickness value) ± 2um. The instrument can be calibrated first and then tested after calibration. Check whether the front end of the probe is intact and place it in a horizontal position on a smooth surface. Note that the probe is perpendicular to the sample. You can also make multiple measurements to reduce accidental errors.

- There is no change in the measurement data of the digital coating thickness gauge. If there is no change in the results measured by the digital coating thickness gauge, you can check whether the probe is damaged, and check the relevant host circuit. If the problem is the data loss caused by abnormal power failure, you can try system calibration.

- The digital coating thickness gauge is turned on but no data is displayed. In this case, there is a backlight and a beeping sound. You can check whether the LCD module is broken, whether the LCD cable is broken due to the external force of the instrument, or whether the related main circuit is faulty. If the thickness of the instrument is immersed in water or oil, you can send the instrument back to the manufacturer for maintenance.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.