Fixed SO2 sulfur dioxide gas detector uses high quality sensors, and advanced micro-process technology, with data display and high/low alarm, fast response, high precision and good stability. Explosion proof, suitable for different kinds of situations.

Anti-magnetic interference

- The fixed sulfur dioxide gas detector can resist the strong magnetic interference of 15V/meter.

- In areas with dense magnetic products or dense electronic products, such as tunnels, mines, confined spaces, etc., the data is guaranteed to be stable and reliable.

Using high-precision sensors

- The fixed online SO2 gas detector is equipped with an infrared remote control as standard, which can realize the functions of alarm point setting, zero point calibration, and address modification without opening the cover.

- Compatible with various control alarms, PLC, DCS and other control systems to realize remote monitoring.

Variety of installation methods

- Wall mounted type, installed on the wall directly, real time monitoring.

- Piping type, installed on the pipeline, monitoring the gas concentration inside.

- Flow type, connected with external sampling pump and tube, measure the gas concentration in enclosed space.

Applications

Fixed sulfur dioxide SO2 online gas detector can detect harmful gas of furniture, flooring, wallpaper, paint and other items, which is widely used in biological pharmaceutical factories, green home, livestock and poultry breeding, greenhouse cultivation, warehousing and logistics, brewing and fermentation, agricultural production, etc.

| Model | GD300-SO2 |

| Detected Gas | SO2 Sulfur Dioxide |

| Measure Range (Optional) | 0-20ppm, 0-50ppm, 0-100ppm |

| Install Method | Wall-mounted, piping type, flow-type |

| Output Signal (Optional) | 4-20mA and RS485 |

| Precision | ≤±3%F.S. (higher precision is available) |

| Zero shift | ≤±1%(F.S./year) |

| Display | 4 digits Nixie tube display. |

| Connection mode | Power connection type: G1/2 male thread explosion-proof flexible pipe Pipe-mounted type: M45*P2.0 |

| Thread Size | M45*2mm |

| Temperature | -20℃ ~ 50℃ |

| Humidity | 0-95%RH (non-condensing) |

| Explosion-Proof | Ex dⅡCT6 |

| Degree of Protection | IP65 |

| Alarm Mode | Sound, light |

| Material | Case: Die-cast aluminum, Sensor housing: aluminum alloy or 316 stainless steel |

| Power | 12-36V DC |

| Weight | 1.6kg |

| Approval | CE, CNEX explosion proof certificate, CMC (China Metrology Certification) |

| Warranty | 12 months |

Note: To measure confined spaces such as pipelines, please contact us and inform the detailed conditions of use.

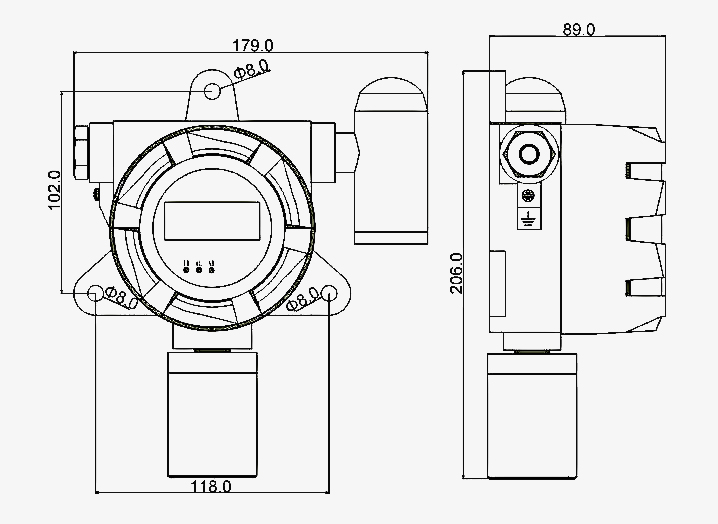

Fixed Sulfur Dioxide (SO2) Gas Detector Dimension (Unit: mm)

Q1: What is a fixed gas detector?

A1: The fixed gas detector is composed of sensors and transmitters, and is installed at the detection site. The secondary instrument consisting of circuit, power supply and display and alarm device is installed in a safe place, which is convenient for staff to monitor. In industrial installations and production processes, fixed gas detectors are generally used, because fixed gas detectors can be installed at specific detection points to detect specific gas leaks.

Q2: What does a gas detector detect?

A2: Combustible gases: Natural gas (methane), liquefied gas, coal gas (hydrogen), acetylene, pentane, alkynes, acetone, toluene, alcohols, hydrocarbons, light oil, etc.

Toxic gases: Carbon monoxide, hydrogen sulfide, ammonia, chlorine, oxygen, phosphine, sulfur dioxide, hydrogen chloride, chlorine dioxide and other toxic and harmful gases.

Q3: Difference between fixed gas detector and portable gas detector

A3: The biggest advantage of fixed gas detectors is 24-hour uninterrupted measurement. As long as the power is turned on, the fixed gas detector is in normal detection work. Portable gas detectors are usually used in confined spaces and confined spaces, but the gas environment in these spaces is usually very complex, and there will be situations such as lack of oxygen and high concentrations of harmful gases.

Tips: Why detect sulfur dioxide?

Sulfur dioxide can cause respiratory problems, especially in children and the elderly, and can exacerbate existing heart and lung diseases. Sulfur dioxide may be produced by improperly ventilated combustion processes, often accompanied by elevated concentrations of nitric oxide, nitrogen dioxide or carbon monoxide. Poor exhaust ventilation, or the intrusion of outdoor pollution sources are not uncommon in indoor air due to various conditions of combustion processes in buildings of various uses. When it happens, it's usually a relatively easy problem to fix. Therefore, it is very necessary to use a sulfur dioxide gas detector to detect SO2.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.