The hot runner temperature controller has multiple channels to choose from, a 4-digit LED display, each thermostat can also be equipped with a set of type K/J thermocouples and heaters, widely used in computers, radio and television, household appliances, electrical equipment, toys and leisure equipment.

Accurate temperature control

- Accuracy of PID continuous temperature control.

- Microcomputer controller guarantee.

- Automatic temperature regulation, extends the life of the heater.

Good heat dissipation performance

- Adopt high-quality plate, the box is light and strong, has anti-corrosion and rust-proof ability.

- Adopt combined structure design, laser cutting, and high precision.

Application

Temperature controllers are widely used in various home appliances, such as water dispensers and heaters. The refrigerator uses a temperature controller to adjust the temperature to keep food fresh. The temperature controller can always control the temperature inside the refrigerator within a certain range. When the temperature is higher than the specified range, the thermostat can automatically cool down.

| Model | SISCO-TEMPC-MS201 |

| Shipping weight | 6~35kg |

| Number of channels * | 1, 2, 3, 4, 5, 6, 8, 10, 12, or other customizable numbers |

| Power supply | 85-245VAC, 50/60Hz |

| Load capacity | 15A (50W-1650W, 110V) / (100W-3600W, 240V) |

| Output type | PWM (Pulse Width Modulation) |

| Display | Every channel has dual 4 digit LED display for PV and SV |

| Temperature sensor type | Thermocouple J type or K type |

| Temperature setting range | 0~450℃ (32~842℉) |

| Temperature accuracy | 0.5%FS |

| Temperature control mode | FUZZY+PID |

| Function | 1. Self-adaption temperature control 2. Automatic environment linear temperature compensation 3. Thermocouple open circuit/reverse/short circuit protection 4. Heater open circuit/short circuit protection 5. Insurance tube open circuit alarm 6. Heater output current monitoring 7. Output percentage view 8. Temperature deviation alarm 9. Leakage error detection 10. Manual output power mode 11. Soft start locking |

| Environment temperature | -10~+55℃ (14~131℉) |

| Environment humidity | 10-80% (No condensation) |

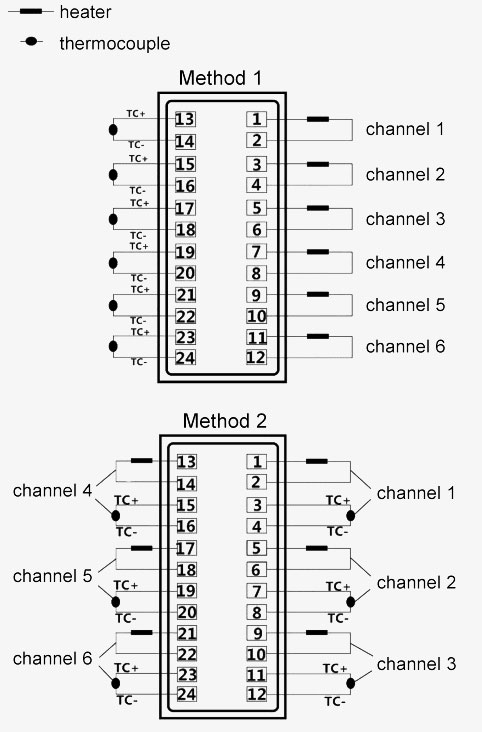

| Cable | 1.5m, Φ10mm, 24 pin cable with heavy duty connector (for thermocouple and heater connection) 1.5m, 5 pin cable with electrical connector (for power supply) |

| Warranty | 2 years |

Note: denotes optional parameters, you can select parameters in drop-down lists to finish your order. Some customizable parameters can't be selected from the lists directly, please contact customer service staff for further communication.

Wiring diagram

Q1: What is a temperature controller?

A1: A thermostat is a series of automatic control elements that generate certain special effects by physical deformation inside the switch according to the temperature change of the working environment, resulting in an on or off action, also called temperature control switch, temperature protector, temperature controller, or thermostat for short. Or through the temperature protector will be temperature to the temperature controller, temperature the controller issues a switch command, so as to control the operation of the equipment to achieve the desired temperature and energy-saving effect.

Q2: What is the working principle of a temperature controller?

A2: Its working principle is to automatically sample and instantly monitor the ambient temperature through the temperature sensor, and the control circuit starts when the ambient temperature is higher than the control setpoint, and the control return difference can be set. If the temperature is still rising, the over-limit alarm function is activated when it rises to the set over-limit alarm temperature point. When the controlled temperature can not

be effectively controlled, in order to prevent the destruction of the equipment can also stop the equipment to continue to run through the function of tripping. It is mainly used in various high and low-voltage switchgear, dry-type transformers, box-type substations, and other related temperature fields used in the electric power sector.

Q3: What is the temperature controller used for?

A3: Digital electronic temperature controller is a precision temperature detection controller, that can be digital quantitative control of temperature, temperature controller is generally used NTC thermal sensor or thermocouple as the temperature detection element.

Tips: What is the soft start effect of the hot runner temperature controller?

The temperature rise of the hot runner temperature controller must conform to the law of heat conduction and heat distribution, requiring a good temperature rise curve. It is not that the faster the temperature rise, the better the temperature control. Too fast a temperature rise not only can not improve productivity but will cause damage to the hot runner and related components.

If the hot runner is not used for the first time, there will be residue inside. If the temperature rises quickly, the residual plastic will be heated first. And the heating will be very uneven throughout the runner, which will result in the residual plastic in the runner near the heating ring being scorched, while the injected plastic away from the heating ring will not be melted. Therefore, soft start is a necessary preheating process that can avoid product failure, plastic hardening or even carbonization and sticking in the inner wall of the hot runner, and long-term blockage of the hot runner which reduces the service life.