SISCO semi-circle type vertical planetary ball mill is a device used for grinding and mixing materials at nanometer scales. Unlike conventional ball mill, this mill features a semi-circular support structure that holds multiple grinding jars (4 jars) arranged vertically. Its semi-circular design not only supports structural integrity but also allows compact construction and ease of operation in laboratory environments. Planetary ball mill commonly used in materials science and chemistry field.

Vertical Planetary Ball Mill Adopts Visual Window

- In traditional mills without visibility, operators must rely on indirect measurements such as vibration, sound, or periodic sampling. With a transparent window, users can directly monitor the milling media, sample behavior, and the progression of the mixing or grinding action.

- Being able to observe the internal environment of the semi-circle planetary ball mill enables more accurate optimization of milling conditions. Through visual inspection, the operator can adjust rotation speed, grinding media size, or sample volume.

- Visual access aids in diagnostics and maintenance. Observing abnormalities such as uneven wear on grinding media, discoloration of samples, or abnormal residue formation helps identify mechanical or process issues early.

Planetary Mechanism

- The combination of rotational and orbital motion increases the kinetic energy of the grinding balls, resulting in stronger impact forces. This allows for faster and more efficient size reduction of materials, especially hard or brittle ones.

- The intense motion in a vertical planetary ball mill ensures uniform energy distribution to the grinding media. This promotes consistent and fine particle size distribution across the entire sample.

Applications

SISCO ball mill is a versatile grinding device used in various industries for reducing materials into fine powders. In the mining industry, it is widely used to grind ores and minerals for metal extraction. In the cement industry, ball mills help grind clinker and other raw materials to produce cement. Overall, the ball mill machine is a critical piece of equipment for materials processing in industrial, laboratory, and manufacturing settings.

Cement Industry

Ceramic Industry

Mineral Processing

Chemical Industry

| Model | SISCO-BM-XQM-2A |

| Specification | 2L |

| Volume of Each Matched Pot | 50-500ml |

| Quantity | 4 pcs |

| Power Supply | 220V 50Hz/ 110V 60Hz |

| Motor Power | 0.75 kW |

| Speed Control Mode | Frequency control |

| Total Run Time of Setting | 1-9999 min |

| Reciprocal Running Time | 1-999 min |

| Adjustable Speed | Revolution: 35-335 rpm; rotation: 70-670 rpm |

| Noise | 60±5 db |

| Dimension | 730*430*550 mm |

| Net Weight | 74 kg |

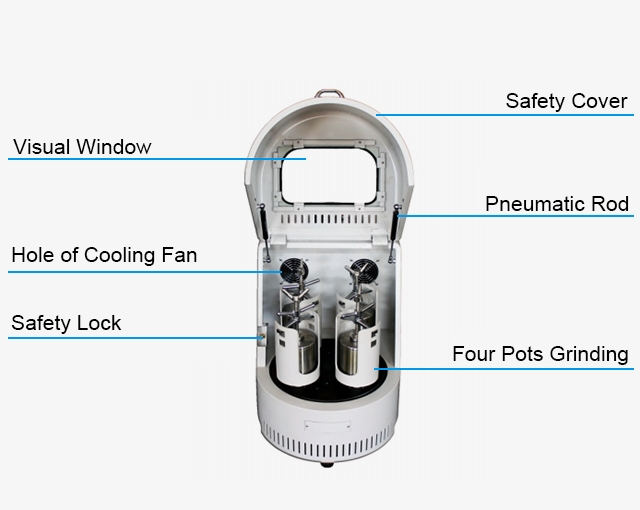

Structure:

Q1: What is a ball mill?

A1: A ball mill is a type of grinding machine used to grind or blend materials into fine powder. It consists of a rotating cylindrical shell filled with steel or ceramic balls, which tumble and crush the material as the mill rotates. Ball mill machine is valued for their efficiency, simplicity, and ability to produce uniform particle sizes suitable for further processing or direct use in various products.

Q2: What are the types of ball mill?

A2: Ball mills are classified based on their operation and design. The main types include horizontal ball mills, vertical ball mills, roller ball mills, stirred ball mills and planetary ball mills, ideal for lab use. Others like batch ball mills process materials in set volumes, whereas continuous ball mills run uninterrupted for large-scale production. Selection depends on application, material properties, and desired particle size. Each type offers unique advantages for specific industrial needs.

Q3: What is a ball mill used for?

A3: A ball mill machine is widely used in various industries for grinding and blending materials. In mining, it grinds ores into fine powders for mineral extraction. In the cement industry, it processes raw materials and clinker. In laboratory, it is used for sample preparation and mechanical alloying. The ability to handle both wet and dry materials makes it versatile. Its effectiveness in producing uniform particle sizes makes ball mill crucial for both research and large-scale industrial applications.

Tips: How to maintain a vertical planetary ball mill?

To maintain a vertical planetary ball mill, regularly inspect and clean the grinding jars, balls, and rotating disc to prevent contamination and wear. Check for abnormal vibrations or noises that may indicate imbalance or damage. Tighten loose screws and ensure the power connections are secure. Calibrate the rotation speed and time settings periodically for accurate operation. Replace worn grinding media as needed. Store the mill in a dry, dust-free environment when not in use.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.