Profilometers

Contact Stylus Profilometer

Stylus Profilometer for Surface Roughness

3D Optical Profilometer

High Precision Optical Surface Profilometer

What is a Profilometer?

A profilometer is a precision instrument used to measure the surface morphology, edge shape, or surface roughness of an object. It uses high-precision sensors to obtain microscopic or macroscopic three-dimensional morphological data of the surface, providing a key basis for quality control and process optimization. Its core function is to obtain the geometric features of the surface of an object through non-contact or contact scanning, including edge shape, curvature, surface roughness, and microscopic morphology.

What are the Types of Profilometers?

According to different working principles, profilometers can be divided into contact profilometers and non-contact profilometers (optical profilometers).

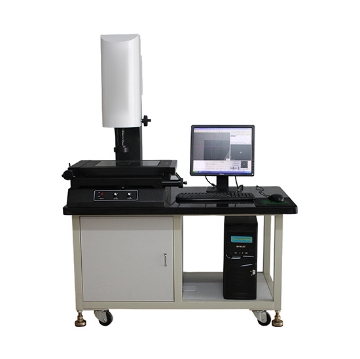

The contact profilometer obtains the surface profile parameters by sliding the stylus across the surface of the object being measured. The displacement change of the stylus is converted into an electrical signal by the sensor, and the relevant parameters of the surface profile are obtained after amplification and processing. It is widely used in mechanical processing, motors, auto parts, precision hardware, precision tools, optical components, and other industries. It is suitable for scientific research institutes, metrology institutions, enterprise metrology rooms, workshops, etc.

The non-contact profilometer (optical profilometer) is based on the principle of white light interference, and converts the interference fringe information obtained by the optical path difference caused by the unevenness of the sample surface into height information to generate a 3D image. It can be widely used in semiconductor manufacturing and packaging process detection, 3C electronic glass screens and their precision accessories, micro-nano materials and manufacturing, automotive parts, and other ultra-precision processing industries and aerospace, national defense and military industry, scientific research institutes, and other fields.

What are the Core Features of the Profilometers?

Through these core features, the profilometer plays an irreplaceable role in scientific research and industrial production, helping users obtain accurate surface morphology data and optimize product quality and process flow.

High-precision Measurement Capability: The use of advanced optical interference technology, precision Z-axis scanning module, or 3D modeling algorithm ensures high accuracy and high repeatability of measurement. Covering nanometer to millimeter level (such as 1 nm~10 mm), suitable for ultra-smooth surfaces (such as disks) to rough machined surfaces (such as castings)

Non-contact Measurement: The optical profilometer adopts a non-contact scanning method to avoid damage to the measured object, and also reduces the error caused by contact during the measurement process. It is suitable for measuring objects with high surface quality requirements and easy to be damaged.

Versatility and Flexibility: Some profilometers have a variety of measurement technologies, such as confocal, interference, and multi-focal plane superposition, etc., and can choose the appropriate measurement method according to different measurement requirements and sample surface characteristics, expanding the application range of the instrument.

Convenience and Efficiency of Operation: It has a user-friendly operation interface, which is simple and intuitive, and supports automated measurement processes, including automatic search for measurement positions, automatic focus, automatic adjustment of brightness, etc., which greatly improves work efficiency. Even non-professionals can easily set up and perform measurements.