Pull Testers

Digital Anchor Pull Tester, 100/200/300KN

Electric Wire Pull Tester for Cable, 500/1000/3000N

Motorized Hydraulic Pull Tester, 500/1000KN

A mechanical device or instrument used to measure whether the connection of an object is firm when subjected to an axial tensile load (tension). Simply put, its core function is to pull something to see how much force it takes to break, or what changes occur during the pulling process.

Differences Between Pull Tester and Tensile Tester

Pull Tester emphasizes dynamic tensile testing and is often used in scenarios such as cables, metal connectors, and welding points to test the breaking strength or durability of materials under continuous tension. Its working principle is to apply a gradually increasing axial tensile force to the connection through a fixture until the connection fails, in order to evaluate the reliability of the connection. In short, the pull tester focuses on "whether the connection is broken."

Tensile Tester focuses on static tensile testing and is used to measure the mechanical properties of materials under uniform tensile loads (such as tensile strength and elongation). It has a wider range of applications, including metals, plastics, rubber, paper, etc. Its working principle is to apply tensile force uniformly along the axial direction of the specimen through a precision loading system, and at the same time cooperate with a displacement sensor to record strain changes to obtain a stress-strain curve, and then analyze the mechanical parameters of the material such as yield strength, ultimate strength and elongation. In short, the Tensile Tester focuses on "how materials deform and break". Both are essentially tensile testing equipment, but the Pull Tester is more inclined to dynamic tensile testing in industrial scenarios, while the Tensile Tester focuses on standardized static testing in laboratory environments.

What Types of Pull Testers are There?

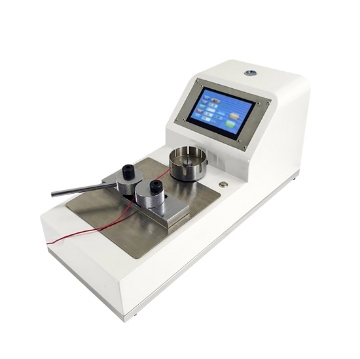

Pull testers can be mainly divided into three categories: manual pull testers, electric pull testers, and servo-controlled pull testers, depending on the driving mode and application scenarios. The manual type is suitable for simple on-site testing, which is easy to operate but has limited accuracy; the electric type is automatically loaded by the motor, with stable force value, suitable for batch testing; the servo-controlled type has high-precision force control and position control functions, and is often used for precision measurement in the laboratory. In addition, according to different test objects, it can also be subdivided into welding wire pull testers, terminal pull testers, plug-in force testers, etc., to meet the pull-out strength testing needs of different industrial connectors.

What are the Core Advantages of Pull Testers?

- Focus on connection strength testing: It is specially designed for testing the pull-off force of connection parts such as solder joints, terminals, cables, and crimping points. It can accurately determine whether the connection is firm and ensure the reliability and safety of the product in actual use.

- Easy operation and high testing efficiency: The equipment has a compact structure, convenient installation, and a simple operation process. It is suitable for rapid sampling or batch testing of production lines to improve quality control efficiency.

- High-precision force measurement: Equipped with a highly sensitive force sensor, it can accurately capture the peak value of the tensile force, ensure that the test data is stable and reliable, and meet the stringent process requirements.

- Strong adaptability: A variety of fixtures can be selected according to different connectors, supporting test objects of various specifications and types, suitable for multiple industries such as electronics, automobiles, and aviation.

- Good data traceability: Some high-end models support digital display, USB export, or connection to a software system, which can record test data, perform statistical analysis, and provide quality traceability.