The anchor pull test equipment controls loading through manual or electric oil pumps, with a simple process. The digital display instrument can directly read the data, and the split design (such as the oil cylinder and oil pump are separated) is easy to carry.

High-precision Visual Integration Solution

- The pull test machine is equipped with a manual pump, a hollow hydraulic cylinder, a digital pressure gauge, a high-pressure hose with a quick connector, and optional accessories (anchors, pull rods, conversion joints), to achieve "one machine for multiple uses".

- The pull tester uses a semi-reflective and semi-transparent color LCD screen, using sunlight-readable technology (Transflective LCD), the picture remains clear in direct sunlight (such as open-air slope detection) or in underground dark environments (tunnel operations), without the need for additional light source assistance.

- Load-time curve (F-t) and force value (KN) can be displayed on the same screen, multi-parameter synchronous detection, and complete detection process data records, providing comprehensive data support for detection.

Intelligent Protection Solution

- The all-stainless steel high-precision sensor, with a measurement accuracy of ≤±5%F.S, can accurately measure the tension and displacement of the anchor rod in real time, ensure the reliability of the test results, and eliminate nonlinear errors.

- Peak hold, automatic shutdown for misoperation, and avoidance of data omission, 10-segment line correction of values, meet the requirements of quality traceability of inspection.

- The overload protection structure is adopted, which can effectively protect the oil cylinder when the no-load exceeds the range and extend the service life.

Applications

Pull tester is widely used in electronic welding strength testing, electrical connection component pull-off testing, automotive wiring harness and terminal crimping quality assessment, and connection reliability verification of adhesive riveted structures to ensure the safety, stability, and long-term durability of various products during use.

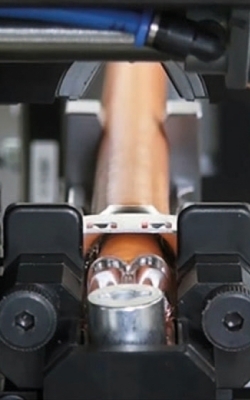

Automotive Wiring Harness

Electrical Component

Terminal Crimping Quality

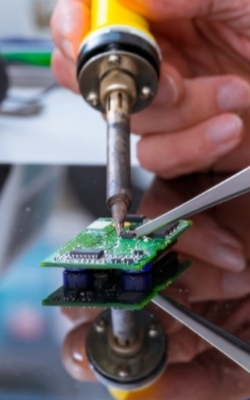

Electronic Welding

| Model | SISCO-PT-DSFAPT | ||

| Pressure Range | 0~100KN | 0~200KN | 0~300KN |

| Indication Error | ≤±1%F.S | ||

| Resolution | 0.01KN | ||

| Force Unit | KN | ||

| Charging Method | 9V Battery | ||

| Center Hole | 27mm | 34mm | 45mm |

| Screen | LED | ||

| Formation | Manual | ||

| Storage | 50 Records | ||

| Peak Value | Yes | ||

| Automatic Shutdown | Yes | ||

| Cylinder Reset | Automatic | ||

| Dimensions | 740mm×175mm×160mm | ||

| Packing Dimensions | 885mm×233mm×240mm/290mm×238mm×275mm | ||

| Weight | 25kg | 33kg | 34kg |

Q1: What types of connectors can be measured by the pull tester?

A1: The pull tester can be used to test various types of connectors, such as solder joints, wire terminals, pins, connectors, cables, crimping parts, bonding or riveting parts, and is widely used in electronics, electrical, automotive, medical, and other industries.

Q2: What is the difference between the pull tester and the universal material testing machine?

A2: The pull tester focuses on the pull-off strength test of the connection part. It has a compact structure and simple operation, which is suitable for rapid on-site testing; while the universal material testing machine is mainly used for mechanical properties testing, such as tension, compression, and bending of the material body. It has higher precision and more complex functions and is often used in laboratories.

Q3: How to ensure accurate test results when using the pull tester?

A3: To ensure test accuracy, the appropriate fixture should be selected according to the test object, the sensor should be calibrated regularly, the appropriate tension speed should be set, and data deviation caused by sample sliding or improper clamping should be avoided.

Tips: What is the Difference Between a Pull Out Tester and a Pull Off Tester?

Pull out tester and pull off tester are both test instruments used to evaluate the separation strength of objects, but they differ in the test objects and the direction of force applied. Pull-out tester is mainly used to detect the pull-out strength of plug-in connectors (such as anchor bolts, screws, terminals), and the force is applied in the direction of pulling out along the connection axis; while pull-off tester is used to test materials attached to the surface such as coatings, adhesive layers, and patches, and the force is applied in the direction perpendicular to the surface being tested, and is used to evaluate adhesion or bonding performance.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.