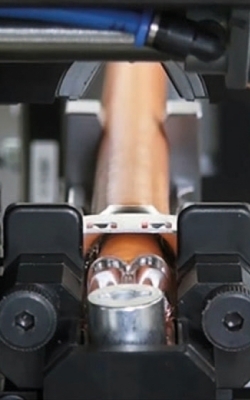

The wire pull test machine supports electric/manual dual-mode switching, is equipped with a high-precision touch screen to display data curves in real time, covers three ranges from 500N to 3000N, and is equipped with a self-tightening clamp to prevent slipping. The body adopts an industrial-grade protective design, which can adapt to long-term use in complex environments. It is widely used in tension and plug-in force tests in the fields of automotive wiring harnesses, electronic connectors, etc.

Automated and Efficient Testing System

- The pull test equipment supports automated testing processes, reduces manual intervention, and improves operational efficiency

- High-precision servo motor drive, using a servo motor control system to ensure a stable testing process and accurate power output

200kgf range coverage - The pull force testing machine has a maximum test load of 200kgf (about 1960N), which meets the tensile testing requirements of conventional wires, solder joints, etc.

Efficient Automated Operation

- 0.01kgf high resolution, force measurement resolution up to 0.01kgf, to ensure data reading accuracy.

- The pull strength tester can switch multiple units in real time, support one-click conversion of kgf, N, lbf, and other units, and adapt to different test standards.

- 360° rotating fixture design, standard fixture can rotate freely, and adapt to different angles of test sample clamping.

Applications

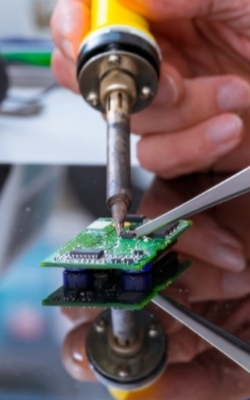

Pull tester is widely used in electronic welding strength testing, electrical connection component pull-off testing, automotive wiring harness and terminal crimping quality assessment, and connection reliability verification of adhesive riveted structures to ensure the safety, stability, and long-term durability of various products during use.

Automotive Wiring Harness

Electrical Component

Terminal Crimping Quality

Electronic Welding

| Model | SISCO-PT-JCQ | ||

| Test Range | 0~500N | 0~1000N | 0~3000N |

| Test Accuracy | ±0.04N | ||

| Test Speed Power | 10~800mm/min | ||

| Power Supply | 100W, AC 220V, 50/60Hz | ||

| Dimensions | 430mm×180mm×210mm | 480mm×260mm×240mm | |

| Weight | 10kg | 12kg | 21kg |

Q1: What types of connectors can be measured by the pull tester?

A1: The pull tester can be used to test various types of connectors, such as solder joints, wire terminals, pins, connectors, cables, crimping parts, bonding or riveting parts, and is widely used in electronics, electrical, automotive, medical, and other industries.

Q2: What is the difference between the pull tester and the universal material testing machine?

A2: The pull tester focuses on the pull-off strength test of the connection part. It has a compact structure and simple operation, which is suitable for rapid on-site testing; while the universal material testing machine is mainly used for mechanical properties testing, such as tension, compression, and bending of the material body. It has higher precision and more complex functions and is often used in laboratories.

Q3: How to ensure accurate test results when using the pull tester?

A3: To ensure test accuracy, the appropriate fixture should be selected according to the test object, the sensor should be calibrated regularly, the appropriate tension speed should be set, and data deviation caused by sample sliding or improper clamping should be avoided.

Tips: Common Operating Errors of Pull Tester

Common operating errors include testing directly without calibrating the equipment, resulting in data deviation; improper force when clamping the sample, too loose and easy to slip, too tight and may damage the sample; the test speed setting does not meet the standard, affecting the accuracy of the results; ignoring the impact of ambient temperature and humidity on material properties; not selecting the sensor range correctly, too large or too small range will reduce the measurement accuracy; not cleaning the equipment and recording data in time after the test, which will bury hidden dangers for subsequent operations.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.