The motorized pull tester is driven by electricity. Compared with traditional hydraulic equipment, it is more energy-efficient and environmentally friendly. Moreover, it is convenient to operate and simple to maintain. It can effectively reduce the usage cost, monitor data in real time, and generate reports, significantly improving the accuracy and efficiency of the test.

Industrial-grade Power and Structure

- The pull force tester integrates a high-precision digital display instrument, directly reads the tensile force value (kN), and features peak value retention, automatic calculation, storage of 200 test data, and query functions. It features a 10-point broken line correction technology, significantly enhancing the instrument's accuracy and ensuring reliable results.

- The large-tonnage hollow hydraulic cylinder is designed with strong adaptability. The core seal adopts imported sealing rings, combined with nickel-plated pistons/sliding sleeves and corrosion-resistant electrostatically sprayed surfaces, providing an extremely long service life and outstanding reliability.

- The dual display configuration of the digital pressure gauge (kN) and pointer megapascal gauge ensures accurate and intuitive data, allowing for quick switching and viewing (kN/MPa). Digital display with backlight, suitable for various environments.

Efficient Automated Operation

- Electric pump drive (220V), efficient and labor-saving operation. Equipped with a precision pressure regulating valve, it achieves controllable pressure, stepwise pressure increase, and stepwise pressure relief, ensuring a smooth, safe, and controllable testing process.

- The display instrument is equipped with a 2000mAh large-capacity rechargeable battery. Combined with an ultra-low power consumption design, it supports continuous operation for more than 72 hours, greatly enhancing the flexibility of on-site operations.

- One-click electric pumping pressure, combined with intelligent digital display data processing (peak hold, storage, calculation), significantly improves testing efficiency and reduces operational burden.

Applications

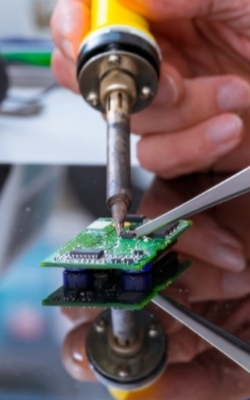

Pull tester is widely used in electronic welding strength testing, electrical connection component pull-off testing, automotive wiring harness and terminal crimping quality assessment, and connection reliability verification of adhesive riveted structures to ensure the safety, stability, and long-term durability of various products during use.

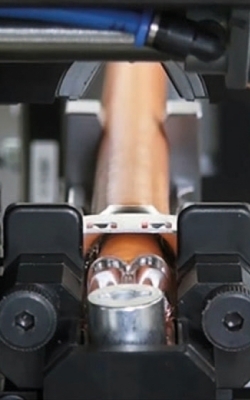

Automotive Wiring Harness

Electrical Component

Terminal Crimping Quality

Electronic Welding

| Model | SISCO-PT-DSFHPT | |

| Measuring Range | 0~500KN | 0~100KN |

| Cylinder Center Hole | 60mm | 86mm |

| Cylinder Stroke | 120mm | 150mm |

| Motor Voltage | 220V | |

| Motor Power | 0.75KW | |

| Cylinder Weight | 30kg | |

| Oil Pump Weight | 25kg | 55kg |

Q1: What types of connectors can be measured by the pull tester?

A1: The pull tester can be used to test various types of connectors, such as solder joints, wire terminals, pins, connectors, cables, crimping parts, bonding or riveting parts, and is widely used in electronics, electrical, automotive, medical, and other industries.

Q2: What is the difference between the pull tester and the universal material testing machine?

A2: The pull tester focuses on the pull-off strength test of the connection part. It has a compact structure and simple operation, which is suitable for rapid on-site testing; while the universal material testing machine is mainly used for mechanical properties testing, such as tension, compression, and bending of the material body. It has higher precision and more complex functions and is often used in laboratories.

Q3: How to ensure accurate test results when using the pull tester?

A3: To ensure test accuracy, the appropriate fixture should be selected according to the test object, the sensor should be calibrated regularly, the appropriate tension speed should be set, and data deviation caused by sample sliding or improper clamping should be avoided.

Tips: What are the Daily Maintenance Methods for Pull Tester?

Pull out tester and pull off tester are both test instruments used to evaluate the separation strength of objects, but they differ in the test objects and the direction of force applied. Pull-out tester is mainly used to detect the pull-out strength of plug-in connectors (such as anchor bolts, screws, terminals), and the force is applied in the direction of pulling out along the connection axis; while pull-off tester is used to test materials attached to the surface such as coatings, adhesive layers, and patches, and the force is applied in the direction perpendicular to the surface being tested, and is used to evaluate adhesion or bonding performance.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.