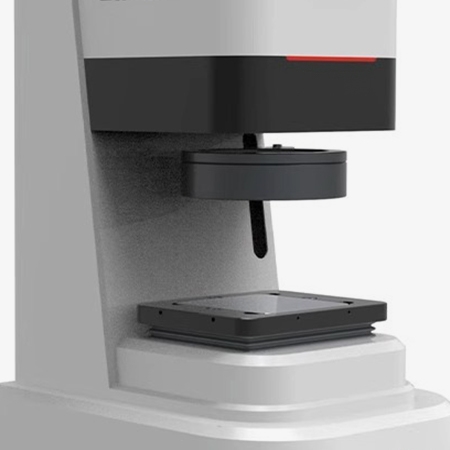

A 3D non contact profilometer can quickly measure the dimensions of parts in batches by simply placing the product on the measuring table. Importing CAD drawings can realize product comparison and offline programming, improving measurement efficiency.

Double Telecentric Lens, Full-size Stable Measurement

- The profilometer measurement, equipped with a double telecentric lens, enables full-size, stable measurements can be achieved. When measuring products, the focus of measurement will not be blurred due to the problem of step difference in focal length.

- The product outline will be automatically captured within the visible range, so that the product will not cause different measurement results due to factors such as personal habits and skills, eliminating human measurement errors.

- Automatically remove burrs or abnormal points, and use the least squares regression method to automatically process them, minimizing the impact on the feature position.

Intelligent Measurement, Image and Drawing, and Integration

- The measurement results can be output in WORD, EXCEL, CAD, and other formats, and the measurement data can be used for SPC statistical analysis to control the production status at any time.

- The 3d profilometer is configured with a high-resolution industrial CCD and sub-pixel image edge processing, large aperture and high depth of field, clear imaging, no distortion of product measurement, and even the edge can ensure the consistency of measurement data, and detailed sub-pixel image edge processing.

- The image and drawing area are shared; what you see is what you get, and can be customized: color, line width, font size, and background color.

Applications

Profilometers are widely used in precision manufacturing, quality control, and scientific research fields, such as testing engine parts (pistons, gears) in the automotive industry, analyzing wafer surface morphology in the semiconductor industry, and evaluating the accuracy of artificial joints in medical devices. They also support mold reverse modeling and scientific research experiments. They are the core tools for measuring surface profile, roughness and form and position tolerances, and help facilitate high-precision product design and process optimization.

Optical Components

Parts Inspection

Precision Hardware

Coating/Plating

| Model | SISCO-PM-DESS100 | ||

| Host | Image Sensor | 20 Million Pixels | |

| Measurement Range | 100mm×80mm | ||

| Magnification | 0.109X | ||

| Display Unit | 0.001 | ||

| Measurement Accuracy | (3.0+L/50MM) μm | ||

| Camera Interface | USB 3.0 transmission interface. (transmission rate: 500MB/s) | ||

| Lens | Double-sided telecentric lens. | ||

| Illumination System | Transmission System | Telecentric light transmission. (green color) | |

| Low Angle Surface Light Source | Moveable up and down programmable LED light source. (color: white) | ||

| Power Supply Voltage | AC 100~240V, 50/60Hz | ||

| Camera Power Supply | Output/ Rated load DC24V0.6A or less | ||

| Measurement Error | ±(3.0+L/100)mm | ||

| Repeatability | ±3.0 | ||

| Dimension | 300mm×530mm×760mm | ||

| Weight | 35kg | ||

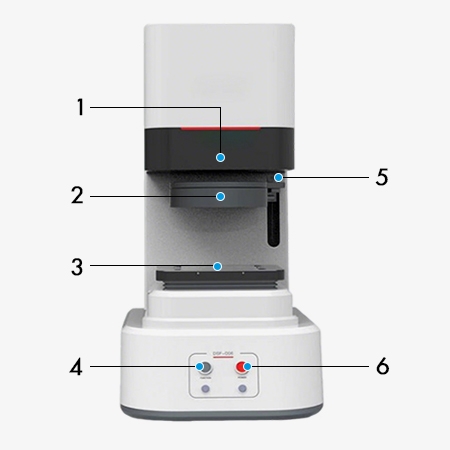

Structure Diagram

- Zoom HD Lens

- LED Light Source

- Mobile Platform

- Measurement Key

- Automatic Axis Shift

- Switch

Q1: What is the difference between a profilometer and a roughness meter?

A1: Profilometer: can measure the complete surface profile and multi-dimensional parameters (such as angle, groove shape), with more comprehensive functions

Roughness meter: dedicated to surface roughness (Ra/Rz) measurement, portable and low cost.

Q2: What parameters can the Profilometer measure?

A2: Basic parameters: Ra (roughness), Rz (maximum profile height), straightness, roundness, angle, groove depth/width, etc.

Advanced analysis: complex geometric features such as surface fitting, groove center distance, convexity, logarithmic curve, etc.

Q3: What are the main types of profilometers?

A3: Stylus profilometer: High accuracy, but may scratch soft materials.

Optical profilometer: Non-destructive testing, suitable for precision optical components or brittle materials.

Laser profilometer: High-speed scanning, suitable for dynamic or large-sized objects.

Tips: What are the Common Misunderstandings in the Use of Profilometers?

Improper Installation of the Stylus: If the stylus is not installed firmly or is not perpendicular to the measured surface, the measurement result will be biased.

Measuring too Fast: It may cause the stylus to jump on the surface of the workpiece, affecting the measurement accuracy.

Unreasonable Measurement Path: If the measurement path is improperly planned when measuring complex-shaped workpieces, some areas may be missed or repeated measurements may be made, affecting the measurement efficiency and results.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.