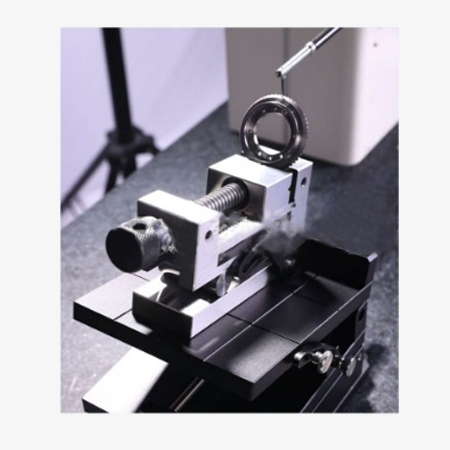

The stylus based profilometer uses a three-axis Hall rocker control, which can freely realize a three-axis linkage to make operation more convenient.

Lightning Data Acquisition

- One measurement can achieve roughness and waviness measurement in the entire range.

- The multi-segment high-precision sensor has an ultra-large range, which maintains the original accuracy of the sensor to the maximum extent.

- The stylus profilometer thickness measurement adopts high-speed parallel data acquisition unit, hardware triggering, hardware high-speed sampling, and no delay; a sufficiently dense and stable data source provides a reliable guarantee for later data processing and calculation.

Professional Software and Hardware Configuration

- The pofilometer measurement is equipped with professional software, which can better analyze the test results and has powerful functions. It comes with a printer to directly print the test results.

- The software system is developed by professional technicians and can be upgraded for free for life.

- The material of the probe is made of imported high-hardness alloy, which is wear-resistant and durable. The base and column are made of marble structure and equipped with grinding-grade, high-precision guide rails.

Applications

Profilometers are widely used in precision manufacturing, quality control, and scientific research fields, such as testing engine parts (pistons, gears) in the automotive industry, analyzing wafer surface morphology in the semiconductor industry, and evaluating the accuracy of artificial joints in medical devices. They also support mold reverse modeling and scientific research experiments. They are the core tools for measuring surface profile, roughness and form and position tolerances, and help facilitate high-precision product design and process optimization.

Optical Components

Parts Inspection

Precision Hardware

Coating/Plating

| Model | SISCO-PM-SPMI200 | ||

| Measuring Range | X-axis Drive | 140mm | |

| Z1 | Contour Measurement Range | 20mm | |

| Z1 | Resolution 0.01° | ||

| Z-axis Height (column) | 500mm | ||

| Minimum inner hole that can be detected. | 5mm | ||

| Contour Technical Parameters | Linear Accuracy | ±(0.8+|0.15H|) μm | |

| Arc | ±(1.0+R/12) μm | ||

| Angle | ±1′ | ||

| Straightness | 0.5μm/100mm | ||

| Evaluation Length | λcX1、2、3、4、5 | ||

| Sensor Resolution | 0.01μm | ||

| Climbing Angle | Ascend 77 degrees and descend 88 degrees | ||

| Measurement Speed | 0.05-20mm/s | ||

| Z-axis Speed | 0.05-20mm/s | ||

Q1: What is the difference between a profilometer and a roughness meter?

A1: Profilometer: can measure the complete surface profile and multi-dimensional parameters (such as angle, groove shape), with more comprehensive functions

Roughness meter: dedicated to surface roughness (Ra/Rz) measurement, portable and low cost.

Q2: What parameters can the Profilometer measure?

A2: Basic parameters: Ra (roughness), Rz (maximum profile height), straightness, roundness, angle, groove depth/width, etc.

Advanced analysis: complex geometric features such as surface fitting, groove center distance, convexity, logarithmic curve, etc.

Q3: What are the main types of profilometers?

A3: Stylus profilometer: High accuracy, but may scratch soft materials.

Optical profilometer: Non-destructive testing, suitable for precision optical components or brittle materials.

Laser profilometer: High-speed scanning, suitable for dynamic or large-sized objects.

Tips: What are the Key Points for Daily Maintenance of the Profilometer?

The core of maintenance is "cleaning and dust prevention, regular lubrication, stable environment, and frequent calibration", which can greatly reduce the failure rate and ensure measurement reliability. Clean with a dust-free cloth and anhydrous alcohol after daily use to avoid dust or oil accumulation. Cover with a shockproof dust cover after shutting down to reduce the intrusion of particles into precision parts. Apply a small amount of high-precision grease (such as lithium-based grease) every month to prevent dry friction and wear of the guide rail. Maintain an ambient temperature of 20±2°C, humidity ≤60%, and stay away from heat sources and vibration.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.