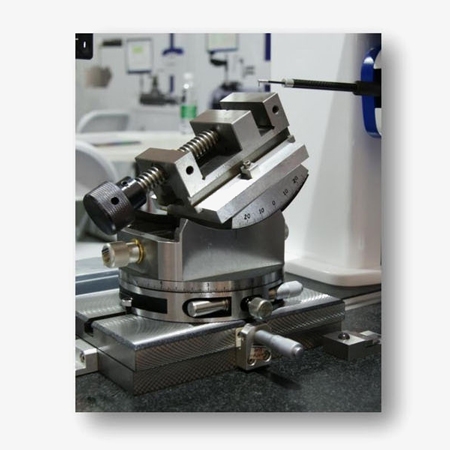

The surface profilometer adopts the latest architecture design and can simultaneously obtain roughness and profile parameters in a single measurement. The software interface is simple and intuitive, and the operation logic is clear, so users can quickly get started.

High-precision Navigation and Automatic Stylus Technology

- The software interface is simple and well laid out. The latest architecture and design style are adopted, which makes it very easy for users to use. One measurement, roughness and contour analysis at the same time, and roughness analysis of different areas of the workpiece can also be performed, with high detection efficiency.

- X-week uses low-friction linear navigation, and X-Z1 week uses high-precision sensors with high accuracy and good linearity.

- The stylus has an automatic function, which can automatically contact, automatically lift, and automatically retract. Through the tracking of the stylus, the maximum point of the workpiece can be detected, and the position is easy to adjust.

Precision Guide Rails and Intelligent Data Management

- The stylus based profilometer uses precision guide rails; the bearing capacity is stronger, the service life is longer, and the accuracy is guaranteed.

- The original data can be automatically recorded, and the software automatically records the initial workpiece alignment position, supports free rotation and alignment of graphics. It can be exported and saved when necessary, which is convenient for multiple annotations.

- Multiple datasets can be merged and converted into a complete profile for analysis.

Applications

Profilometers are widely used in precision manufacturing, quality control, and scientific research fields, such as testing engine parts (pistons, gears) in the automotive industry, analyzing wafer surface morphology in the semiconductor industry, and evaluating the accuracy of artificial joints in medical devices. They also support mold reverse modeling and scientific research experiments. They are the core tools for measuring surface profile, roughness and form and position tolerances, and help facilitate high-precision product design and process optimization.

Optical Components

Parts Inspection

Precision Hardware

Coating/Plating

| Model | SISCO-PM-TSLK100 | ||

| Profile Parameters | Measurement Range | X Axis | 100mm (resolution 0.1μm) |

| Z Axis | 500mm | ||

| Z1 Axis | 40mm (resolution 0.05μm) | ||

| Contour Accuracy | X-Axis Indication Error | ≤(0.8+0.03L)μm | |

| Z1 Axis Indication Error | ≤(0.8+∣0.08H∣)μm | ||

| Arc Measurement Error | ≤(1.2+R/8)μm | ||

| Angular Accuracy | ≤±1' | ||

| Straightness | 0.8μm/100mm | ||

| Roughness Parameters | Residual Noise | ≤0.010μm | λc is 0.08mm, the measuring speed is 0.1mm/s, and the flat crystal is measured |

| Roughness Measurement Repeatability | 1δ≤2nm | Adopt square wave standard parts with Ra of 0.35~0.5μm | |

| Roughness Indication Error | ≤±(10nm+3.5%) | ||

| Roughness Indication Stability | ≤±7% | ||

| Roughness Measurement Repeatability | ±3% | ||

| Evaluation Length | λc×1,2,3,4,5,6,7 | ||

| Cutoff Wavelength | 0.025,0.08,0.25,0.8,2.5,8mm | ||

| Filter | Gaussian Filter | ||

| Climbing Angle | 77°up, 88°down | ||

| Test Speed | 0.02~5.0mm/s | ||

| Measurement Method | Sensor Movement | ||

| Power Supply | AC 220V±10% 50Hz | ||

| Ambient Temperature | 20℃±2℃ | ||

| Ambient Humidity | 40%~60%RH | ||

| Dimensions | 1005mm×900mm×1850mm | ||

| Weight | 420kg | ||

Q1: What is the difference between a profilometer and a roughness meter?

A1: Profilometer: can measure the complete surface profile and multi-dimensional parameters (such as angle, groove shape), with more comprehensive functions

Roughness meter: dedicated to surface roughness (Ra/Rz) measurement, portable and low cost.

Q2: What parameters can the Profilometer measure?

A2: Basic parameters: Ra (roughness), Rz (maximum profile height), straightness, roundness, angle, groove depth/width, etc.

Advanced analysis: complex geometric features such as surface fitting, groove center distance, convexity, logarithmic curve, etc.

Q3: What are the main types of profilometers?

A3: Stylus profilometer: High accuracy, but may scratch soft materials.

Optical profilometer: Non-destructive testing, suitable for precision optical components or brittle materials.

Laser profilometer: High-speed scanning, suitable for dynamic or large-sized objects.

Tips: How to Use a Profilometer?

First, for large or irregularly shaped workpieces, they must be firmly fixed to avoid movement or shaking during measurement. According to the shape of the workpiece and the measurement requirements, select a suitable probe, and then set the measurement parameters in the measurement software, such as measurement range, measurement speed, number of sampling points, etc., and select the appropriate measurement mode and analysis function. During the measurement process, the measurement environment must be kept stable to avoid external factors interfering with the measurement results.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.