The optical profilometer mainly measures two-dimensional coordinates, including geometric elements such as lines, circles, arcs, rectangles, and the length, angle, contour, and surface shape of parts. It can also make three-dimensional auxiliary measurements, such as hole depth and surface flatness.

High Restoration, Fast Focus, Precise Imaging Professional Choice

- High resolution color CCD, high RGB restoration, high-definition effect, automatic white balance adjustment, high-quality picture. With special light source treatment, the image illumination is still bright at a large magnification, the color distortion is small, and the image boundary is clearer.

- High frame rate movement without delay, fast and accurate image focus, one focus action, 1/2 second to complete, focus repeatability can reach 0.002mm/0.003mm.

- Optical profilometer surface roughness uses precision-grade guide rails, which have stronger load-bearing capacity, longer life, and guaranteed accuracy.

High-Precision, Space-Saving Intelligent Measurement Solution

- Surface profilometer has high measurement accuracy and reduces errors. The base X and Y workbench columns are made of high-quality marble (material deformation is almost zero) to ensure measurement accuracy.

- The software uses the instrument's bottom light source and surface light source to accurately grasp the edge contour and surface size of the part. The operation is as convenient as AutoCAD. When measuring large workpieces, there is no need to move the workbench back and forth.

- Optical profilometer uses full-screen and half-screen measurements to switch freely. The cantilever structure occupies a small space and is easy to operate.

Applications

Profilometers are widely used in precision manufacturing, quality control, and scientific research fields, such as testing engine parts (pistons, gears) in the automotive industry, analyzing wafer surface morphology in the semiconductor industry, and evaluating the accuracy of artificial joints in medical devices. They also support mold reverse modeling and scientific research experiments. They are the core tools for measuring surface profile, roughness and form and position tolerances, and help facilitate high-precision product design and process optimization.

Optical Components

Parts Inspection

Precision Hardware

Coating/Plating

| Model | SISCO-PM-VMS3020 | |

| Workbench | Marble Table Size | 470mm×360mm |

| Glass Table Size | 338mm×238mm | |

| XY Axis Travel | 300mm×200mm | |

| Focusing Travel | 160mmmm | |

| Measuring and Aiming System | High-Resolution SONY Chip Color Camera (CCD) | |

| High-Definition Telecentric Lens with Positioning (Magnification 20X~180X) | ||

| 0.001mm Resolution Grating Ruler | ||

| Specialized Measurement Software | ||

| Indication Error | X/Y≤(3+L/200)μm | |

| Lighting System | Adjustable LED Parallel Contour Cold Light Source | |

| Power Supply | 220V | |

| Dimensions | 750mm×700mm×1000mm | |

| Weight | 200kg | |

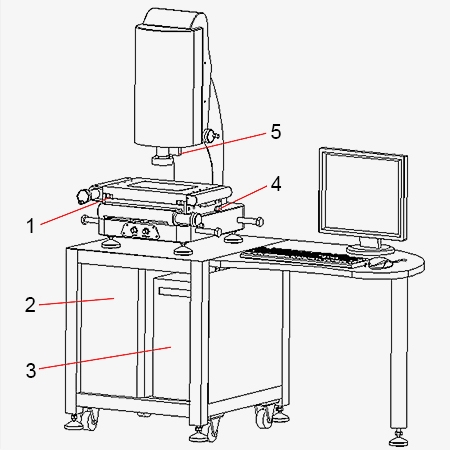

Structure Diagram

- Y-axis Transport Fixing Block

- Instrument Table

- Computer Host

- X-axis Transport Fixing Block

- Z-axis Transport Fixing Block

Q1: What is the difference between a profilometer and a roughness meter?

A1: Profilometer: can measure the complete surface profile and multi-dimensional parameters (such as angle, groove shape), with more comprehensive functions

Roughness meter: dedicated to surface roughness (Ra/Rz) measurement, portable and low cost.

Q2: What parameters can the Profilometer measure?

A2: Basic parameters: Ra (roughness), Rz (maximum profile height), straightness, roundness, angle, groove depth/width, etc.

Advanced analysis: complex geometric features such as surface fitting, groove center distance, convexity, logarithmic curve, etc.

Q3: What are the main types of profilometers?

A3: Stylus profilometer: High accuracy, but may scratch soft materials.

Optical profilometer: Non-destructive testing, suitable for precision optical components or brittle materials.

Laser profilometer: High-speed scanning, suitable for dynamic or large-sized objects.

Tips: What parameters does the profilometer mainly look at?

Roughness Parameters: Ra (average roughness), Rz (peak-to-valley height), Rt (maximum roughness).

Geometric Parameters: straightness, roundness, convexity, groove width/depth, groove curvature radius.

Profile Analysis: logarithmic curve, profile, horizontal/vertical distance.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.