A lab roller ball mill is a compact, versatile grinding machine used in laboratories for mixing and grinding materials into fine powders. As the rollers turn, they rotate the container, causing the grinding media to tumble and crush the material inside. Its ease of use, efficiency, and ability to work with both dry and wet samples.

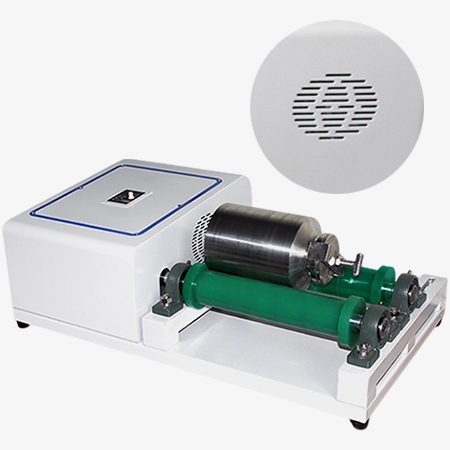

Cooling Fan Hole in Lab Roller Ball Mill

- A cooling fan hole dissipates the heat generated, helping to maintain a stable internal temperature. This is particularly important when working with polymers, organic compounds, or volatile substances that may degrade or react under high temperatures.

- Many materials milled in laboratory settings are sensitive to heat. Excessive temperatures can cause phase changes, oxidation, or decomposition. A cooling fan hole helps ensure that these materials are processed under controlled thermal conditions, preserving their chemical and physical properties.

- Overheating can lead to premature wear, increased maintenance, and ultimately, equipment failure. Cooling fan hole helps protect these components, extending the lifespan of the roll ball mill and reducing downtime and repair costs.

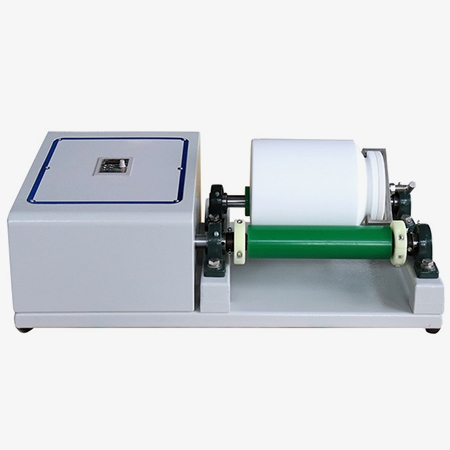

Roll Ball Mill With Compact Structure

- Laboratories often have limited work areas filled with various instruments and materials. A roller ball mill with a small footprint allows researchers to maximize available space without compromising on functionality.

- Compact roll ball mills are typically lighter and easier to move than their larger counterparts. This makes it feasible to transport them between workstations or even laboratories. It can be placed flexibly and enables shared use among different departments or teams, enhancing the overall utility of the equipment.

- Smaller roller ball mills can be engineered to minimize vibration and noise, which are common concerns in lab environments. A compact, rigid structure ensures better damping of mechanical vibrations and reduces noise levels during operation.

Applications

SISCO ball mill is a versatile grinding device used in various industries for reducing materials into fine powders. In the mining industry, it is widely used to grind ores and minerals for metal extraction. In the cement industry, ball mills help grind clinker and other raw materials to produce cement. Overall, the ball mill machine is a critical piece of equipment for materials processing in industrial, laboratory, and manufacturing settings.

Cement Industry

Ceramic Industry

Mineral Processing

Chemical Industry

| Model | SISCO-BM-QM-5 | SISCO-BM-QM-15 |

| Motor Power | 0.37 kW-4B3 | 0.75 kW-4B3 |

| Frequency Converter Spec | 0.4 kW 220V/110V | 0.75 kW 220V/110V |

| Rotation Speed Range | 60-570 rpm±10 | 60-570 rpm±10 |

| Adjusted Space Between Rollers | 120 mm | 140 mm |

| Available Length of Station | 260 mm | 340 mm |

| Max Load Weight | 35 kg | 80 kg |

| Dimension | 730*415*260 mm | 845*435*270 mm |

| Net Weight | 32 kg | 43 kg |

Q1: What is a ball mill?

A1: A ball mill is a type of grinding machine used to grind or blend materials into fine powder. It consists of a rotating cylindrical shell filled with steel or ceramic balls, which tumble and crush the material as the mill rotates. Ball mill machine is valued for their efficiency, simplicity, and ability to produce uniform particle sizes suitable for further processing or direct use in various products.

Q2: What are the types of ball mill?

A2: Ball mills are classified based on their operation and design. The main types include horizontal ball mills, vertical ball mills, roller ball mills, stirred ball mills and planetary ball mills, ideal for lab use. Others like batch ball mills process materials in set volumes, whereas continuous ball mills run uninterrupted for large-scale production. Selection depends on application, material properties, and desired particle size. Each type offers unique advantages for specific industrial needs.

Q3: What is a ball mill used for?

A3: A ball mill machine is widely used in various industries for grinding and blending materials. In mining, it grinds ores into fine powders for mineral extraction. In the cement industry, it processes raw materials and clinker. In laboratory, it is used for sample preparation and mechanical alloying. The ability to handle both wet and dry materials makes it versatile. Its effectiveness in producing uniform particle sizes makes ball mill crucial for both research and large-scale industrial applications.

Tips: How does a lab roller ball mill work?

A lab roller ball mill works by rotating one container filled with grinding media (usually mill balls) and material to be milled. The containers rest on rollers that spin, causing the contents to tumble and collide. This motion reduces particle size through impact and friction. The speed, duration, ball size, and material all influence the grinding efficiency and final particle size.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.