Come with 7 inch touch screen display, air leakage testing equipment can work at 5℃~40℃, AC 220V 50Hz. The fixture of the air leak tester can be customized. Leakage unit kpa (other units optional), accuracy up to 0.1pa. Air leak tester machine can be widely applied in automotive parts, medical devices, mobile phones, cameras, valves.

Colored and clear touch screen, easy to operate

- The touch screen, as the operating interface of the air leak detector, provides an intuitive interactive platform. Through the touch screen, you can enter the test parameters and select the mode without complicated key operations, which simplifies the operation process of the air pressure leak tester.

- During the test, the touch screen of the leak tester can display key data such as test pressure, leakage rate, test time, etc., in real time, allowing users to understand the test progress and results instantly.

- This is of great significance for timely adjusting test parameters and judging the sealing performance of the pressure leak tester. At the same time, the touch screen also supports exporting or printing data, which is convenient for users to compile and archive reports.

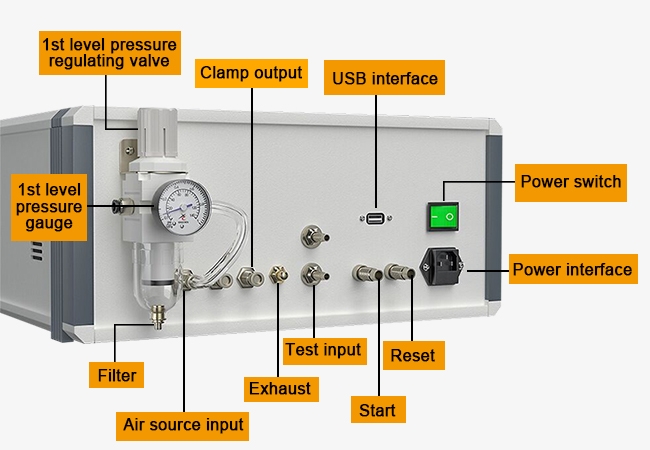

Come with a pressure regulating valve and a USB interface to ensure smooth test

- Equipped with a precision pressure regulating valve, it is convenient to adjust the test pressure of the pressure leak tester, and the pressure display gauge can observe the test pressure in real time.

- The USB interface on the back of the air leak tester machine is convenient for data connection, and the fixture can be connected according to the test requirements.

- Users can flexibly control the test process of the air leak tester, query data, and perform calibration and reset operations, thereby ensuring that the sealing performance test of the air leakage testing equipment can be carried out smoothly.

Air Pressure Leak Tester Host Structure

Application

Air pressure leak testers can be used to assess the sealing performance of electronic components, including automobile engines, transmissions, braking systems, doors, windows, roofs, and other elements. An air leak tester can also be used to detect leaks in batteries, valves, and smart electronic devices, among other applications.

Valves

Vials

Smart Devices

Batteries

| Model | SISCO-VLD-YD-T02 | ||

| Detection Pressure Range | 1kpa~800kpa (optional) | ||

| Pressure Sensor Range | 1kpa~800kpa | ||

| Resolution 0.1~200pa | |||

| Detection Mode | Positive pressure test | ||

| Accuracy | 0.1pa | ||

| Number of Test Channels | Single channel | ||

| 10 Interface | Input signal 2 / output signal 5 | ||

| Show | 7 inch touch screen display | ||

| Unit | kpa (other units available) | ||

| Curve | Graph from inflation to exhaust | ||

| Time | Tour name | Minimum value (S) | Maximum value (H) |

| Filling/inhaling | 0.1 | 9999 | |

| Holding pressure | 0.1 | 9999 | |

| Size | 500*400*190 (mm) Length*Width*Height | ||

| Host Weight | About 15kg, the fixture can be customized | ||

| Power Supply | AC 220V ±10%, 50/60Hz | ||

| Power Consumption | 35W ~ 50W | ||

| Test Gas Source | Use a clean air source (such as an air compressor) with large flow and high pressure, and connect it to a stable air pressure source adjusted by a pressure regulating valve. | ||

| Ambient Temperature | The operating temperature is 5℃~40℃, the storage temperature is -10℃~50℃, below 80% RH, but without condensation. | ||

Q1: What is an air leak detector?

A1: An air leak detector, also known as a sealing detector or a leak detector, is a key device used in the field of industrial manufacturing to detect the sealing performance of products. Its core function is to accurately measure the amount of tiny leaks to ensure that the sealing performance of the product meets the design requirements.

Q2: How does an air pressure leak tester work?

A1: The object to be tested is placed in a closed test chamber, and a certain pressure of compressed gas is filled into the object to be tested so that the pressure in the chamber reaches the preset test pressure. Subsequently, the leak detector monitors the changes in the pressure in the chamber in real time, and then monitors the changes in pressure to evaluate its sealing performance.

Q2: What is an air leak tester used for?

A1: An airtight leak detector is a high-precision testing device that is widely used in many industries such as medicine, food, cosmetics, and medical devices.

Tips: What is the air pressure leak tester's positive pressure principle?

A certain pressure of gas (usually dry air or nitrogen) is filled into the object to be tested (such as packaging, electronic components, etc.) to make the internal pressure higher than the external environment, forming a positive pressure state. After the inflation is completed, the gas source is cut off and the airtight state is maintained for a period of time. The pressure change is monitored by a high-precision sensor. If the pressure drop exceeds the preset threshold, it is judged as a leak.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.