A handheld particle counter is an instrument used to detect the number of dust particles and their distribution per unit volume in a clean environment. sisco portable particle counter with 320X240 high-resolution LCD display, which can be connected to PC data acquisition system for remote control and direct observation of the instrument's test situation, and the test data can be analyzed and processed through the computer and can be saved as an Excel file.

Computer connection port

- Test data can be analyzed and processed by computer and saved as an Excel file.

- Six particle sizes can be counted simultaneously, 0.3, 0.5, 1.0, 3.0, 5.0, and 10μm.

- High-resolution LCD screen.

Rechargeable battery

- 2600mAh large capacity battery, full charge working time up to 8 hours.

- Multifunctional particle counter provides high accuracy and response speed block.

- Handheld design, compact size, easy to carry, measurement at any time.

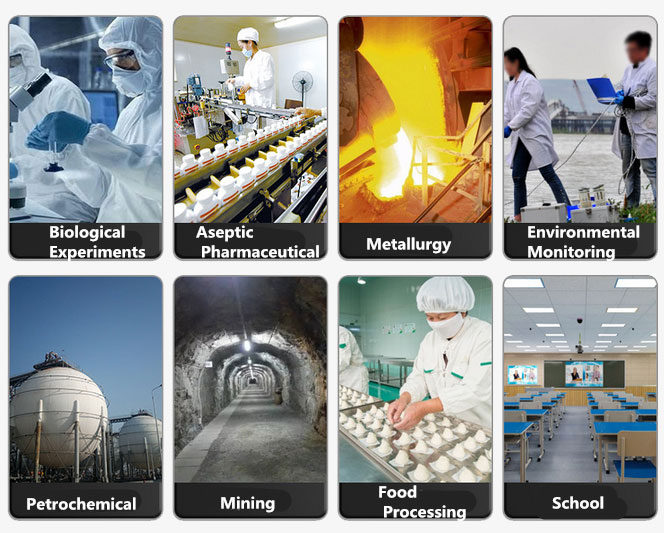

Application

Particle counters have a wide range of applications, such as the processing of precision electronics, testing filters, pharmaceutical plants in the pharmaceutical industry, drug testing laboratories to test the cleanliness of hospitals, hospital operating rooms, air purification industry. The design of some clean workshops or clean rooms, the construction units, and the processing of precision electronic devices related to purification equipment all require the use of particle counters.

| Model | SISCO-QT-3016H |

| Light Source | Semiconductor laser |

| Flow Rate | 2.83L/min (0.1ft3) |

| Display Mode | last cycle display, real-time concentration display, can display time, date, measured value, the temperature and humidity, room number, sampling points, sampling times, battery power, status and other parameters, the 95% UCL calculation, can directly display the concentration of particles (particles / cubic meter) |

| Battery | Lithium-ion battery, 16.8 V, 2600mAh. |

| Power Supply | AC power adapter, AC:100V~245V, 50/60 Hz to DC:16.8V,1A |

| Operating Time | 8 Hours (remaining power indication) |

| Counting Mode | Total value, difference value, concentration value |

| Test Mode | Single, Repeat, Continuous, Calculated, Remote |

| Unit Conversion | Units can be converted to m3, ft3 |

| Particle Size Channel | 0.3, 0.5, 1.0, 3.0, 5.0, 10μm, six particle sizes counted simultaneously. |

| Sampling Period | 1~10 (min); delayed counting: 0~99 (S); self-purification time: ≤10 (min) |

| Working Temperature | 0~40°C (50~104°F) |

| Relative Temperature | 20~90%RH |

| Non-Condensing Atmospheric Pressure | 86-106KPa |

| UCL Setting | Number of sampling points(A) : 2~9 points setting. Number of sampling times per point(L) 2~9 times setting. Measuring position: 0-999 |

| UCL Report | Conform to IS014644-1, GB50073-2001, GMP, FS-209E standard |

| Data Storage | 1000 sets of data can be stored, no data loss after power failure |

| Communication Interface | RS232, 9600 baud rate |

| Alarm Settings | The instrument with level alarm function, can be clean room 100 level, 1000 level, 10000 level, 100000 level, 300000 level, 1000000 level alarm after exceeding the standard |

| Overlap Error | 5 % at 2,000,000 grains/cubic foot |

| Printing Function | External printer (optional) |

| Dimension | 230 x 130 x 45(mm) |

| Weight | 0.6kg |

| Standard Features | Carrying case/charger, zero filter, USB to RS 232 module, RS 232 connection cable, and Computer connection communication software CD |

Dimension Unit (mm)

Q1: How to use the handheld particle counter?

A1: The particle counter is simple to use, first determine the number of test points according to the area of the clean room and distribute the test points evenly in the clean room, then set the measurement time, measurement unit, flow rate, and other parameters of the particle counter, then put the particle counter on the plane of 1~1.2 meters height from the ground in the middle of the sampling point, and finally start to test the sampling and record the data one by one.

Q2: How to change the printing paper of the particle counter?

A2: Generally, the printing part of the particle counter has a cover, some covers can be lifted directly to cover, lift it to replace the printing paper, and some need to use a screwdriver to unscrew the screw, the specific instructions are also introduced, open the cover to follow the thermal printing paper can be replaced.

Q3: How to read the dust particle counter?

A3: The results of the dust particle counter, generally the left column is the particle diameter, and the right column is the number of particles per cubic meter.

Tips: What does a dust particle counter consist of?

The dust particle counter is mainly composed of five parts: a light source, two sets of lenses, a measuring chamber, a light detector, and an amplification circuit. Among them, the light source affects the performance of the counter and is one of its key components, which needs to meet the characteristics of long life, high stability, and not easy to be disturbed by outside. Two sets of lenses are used to complete the function of focusing, one set is used to focus the light from the light source, and one set is used to focus the scattered light generated by the scattering phenomenon. The measuring chamber is used to make the air particles scatter under the light. The light detector is used to convert the light pulse signal into an electrical pulse signal. The amplifier circuit is used to amplify the weak electrical signal and select the pulse signal to meet the requirements.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.