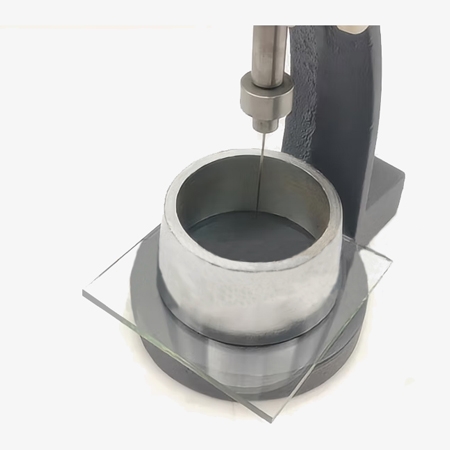

The Vicat Apparatus Test for Cement is a standardized device used to determine the setting time of cement, including both the initial setting time and final setting time. This test evaluates the time required for cement paste to transition from a fluid to a hardened state under controlled conditions, which is critical for construction scheduling and quality control.

Simple structure and easy operation

-

Usually composed of a base, it is an adjustable sliding rod, needle, or probe (such as an initial setting needle, final setting needle, or round head probe), a mold, etc.. The structure is intuitive and convenient for daily testing, operation, and maintenance.

-

By using a standard load (300g) and precise probe insertion depth, the repeatability and consistency of the results are ensured, which helps to accurately determine the initial and final setting time of cement.

-

The Vicat Apparatus Test for Cement is mostly made of stainless steel and high-strength alloy materials, which are suitable for frequent experimental environments and ensure stable performance under long-term use.

Compliant with standard specifications

-

The Vicat Apparatus Test for Cement can be adjusted in size, sturdy and firm, finely crafted, and has a long service life.

-

The Vicat Apparatus Test for Cement has a Vicat instrument originally made of long-lasting steel, durable, and of standard size.

- It uses Vicat gauge needles, stainless steel initial setting needles, anti-corrosion and rust-proof, with a long service life.

Applications

The Vicat Apparatus is primarily used to determine the initial and final setting times of cement, gypsum, and other binding materials. It is widely applied in construction material laboratories for routine cement setting tests. Cement manufacturers for quality control and production optimization.Educational institutions and research centers for materials research and teaching purposes.Construction sites for on-site evaluation of material setting behavior.

Cement Plants

Concrete & Precast Plants

On-site Construction

Construction Materials Labs

| Model | SISCO-SH-ISO |

| Weight of Sliding Parts | 300±1G |

| Maximum Travel of the Sliding Part | 70mm |

| Thickness Test Rod Diameter | 10±0.05mm |

| Test Needle Diameter | 1.13±0.05mm |

| External Dimensions | 170mm*110mm*300mm |

Details

Q1: What is the Vicat Apparatus Test?

A1: Vicat Apparatus Test is an experimental method used to determine the standard consistency, initial setting time, and final setting time of cement. This test helps evaluate the workability and hardening performance of cement during construction.

Q2: Why conduct Vicat Apparatus testing?

A2: To determine the standard viscosity for subsequent mixing ratio control. Measuring the initial and final setting times can help arrange construction processes, prevent early water loss, control cement quality and consistency, and ensure compliance with relevant standards.

Q3: How to conduct standard consistency testing?

A3: Mix a certain amount of cement with water and use a standard needle (diameter 1.13mm, length 50mm) on a Vicat Apparatus Test for Cement to check if the needle can penetrate the paste within a depth of 30 ± 1mm. Adjust the water volume multiple times until the condition is reached, and the proportion of water used is the standard consistency.

Tips: How to ensure the accuracy and standardization of its use?

- Sample preparation should be standardized, using standard water usage (determined by standard consistency testing) to prepare cement slurry, and after mixing, it should be quickly molded.

- The mold should be clean and dry. Before testing, ensure that the Vicat mold is clean and dry to avoid residual moisture or slurry affecting the test results.

- The needle is clean and undamaged. Before each test, check whether the standard needle is bent or worn, and maintain its original shape.

- To avoid manual interference, use a standard device to gently place the needle on the surface of the cement slurry to prevent human force from affecting the penetration depth.

- The reading should be timely, and the penetration depth should be recorded immediately after inserting the pin. Especially in the stage of approaching the setting time, frequent testing should be carried out.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.