The electronic load tester is suitable for all 12V batteries, can directly detect damaged batteries, and features reverse polarity protection. A car battery voltage tester accurately measures the actual cold-cranking current capability of a vehicle's starting battery, providing troubleshooting assistance during vehicle repairs. The car battery checker operates in temperatures ranging from 0°C to 50°C (32°F to 122°F).

With a data print function, suitable for automotive starter lead-acid batteries

- The motorcycle battery tester features a data print function, allowing you to print recorded test data or customized test reports. Test information can be printed from a computer via a USB port.

- 12V battery capacity tester can test all automotive starter lead-acid batteries, including standard lead-acid batteries, AGM flat-plate batteries, AGM wound batteries, and gel batteries.

- The lithium battery capacity tester features reverse polarity protection, ensuring reverse polarity will not damage the tester, the vehicle, or battery.

- An electric vehicle battery tester can be tested even when the battery is low, eliminating the need to fully charge the battery tester before testing.

- The battery health tester can directly detect damaged batteries.

The color LCD tests the overall status of vehicle systems

- The car battery charger tester is suitable for global cars, SUVs, lawn mowers, motorcycles, and boats. Equipped with a wide range of battery types and test items, the battery capacity tester 12V supports CCA input, allowing testing on a wider range of motorcycles.

- The 12-volt battery checker displays state of health (SOH), state of charge (SOC), voltage, current, rated value, and clear, easy-to-read analysis results on a backlit color LCD.

- The motorcycle battery load tester complies with multiple measurement standards: CCA, BCI, CA, MCA, JIS, DIN, IEC, EN, and SAE.

- The battery load checker tests various components of the charging system, including the alternator, rectifier, and rectifier diode, to obtain reliable charging voltage values.

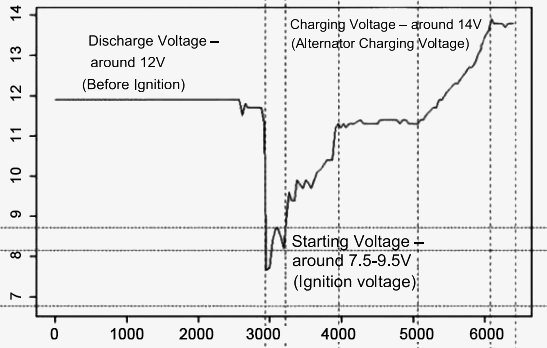

- The 12v battery checker analyzes actual cranking voltage and cranking time, helping you quickly understand the overall status of the starting system.

Various Vehicle Voltage Analyses

Application

On automobile production lines, battery testers are used to check the performance of newly installed batteries. In power infrastructure security, power plants and substations use charge and discharge testers to monitor the capacity and internal resistance of backup battery packs to ensure stable grid operation. In electric vehicle production and maintenance, battery testers can monitor battery performance and ensure power system reliability.

New Energy Industry

Power Communications

Battery Recycling

Automobile Production

| Model | SISCO-BT-BT900 |

| Display | LCD |

| Applicable To | All 12V batteries |

| Operating Temperature | 0°C to 50°C / -32°F to 122°F |

| Storage Temperature | -20°C to 70°C / -4°F to 158°F |

| Power Supply | Powered by car battery cable |

| Measurement Standards | CCA, BCI, CA, MCA, JIS, DIN, IEC, EN, SAE |

| Application Area | Applicable to automakers, auto repair shops, auto battery manufacturers, auto battery dealers, educational institutions, etc. |

Q1: What is a vehicle battery tester?

A1: A battery meter (also known as a battery tester or detector) is an electronic device specifically designed to assess battery performance, health, and remaining life. It is widely used in the automotive, power, communications, and railway sectors.

Q2: What does a vehicle battery tester do?

A2: Battery meters are primarily used for voltage testing, basic health status, internal resistance/conductance testing, capacity testing, cold cranking current (CCA) testing, and state-of-health (SoH) analysis, identifying the risk of capacity degradation reaching critical values (e.g., 80%).

Q3: How does a vehicle battery tester work?

A3: The working principle of the battery tester adopts different technical methods according to its type and detection target (such as voltage, internal resistance, capacity, etc.), which are mainly divided into conductivity/internal resistance test method, discharge test method and charge and discharge cycle test method.

Tips: How to use a car battery tester correctly?

Check the battery meter's electrodes and select the test leads. Turn off the power and connect the cables correctly, connecting the red clip of the battery meter to the positive (+) terminal and the black clip to the negative (-) terminal. When setting parameters, avoid strong electromagnetic fields or vibrations that may interfere with the signal.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.