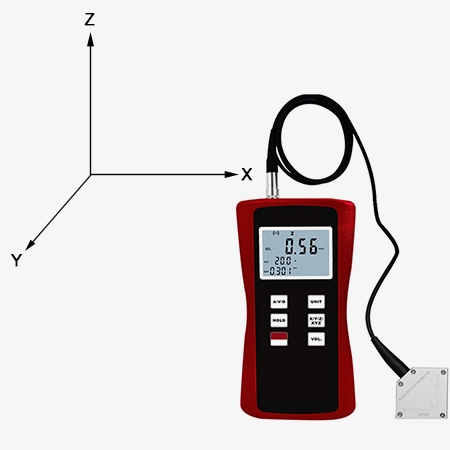

A 3-axis vibration meter is a device used to measure vibration levels in three perpendicular directions: X, Y, and Z axis or XYZ axis. It helps assess the condition of machinery, structures, or environments by detecting and recording vibration data simultaneously across all axes. Compared with a vibration meter that can only measure in a single axis, this kind of vibration tester can make more accurate diagnoses.

Support 3-axis (single-axis X, Y, Z or 3-axis XYZ) Measurement

- There are 4 choices of this vibration tester: X, Y, Z, XYZ axis. Not only measure in a single axis, by capturing data from all directions simultaneously, a 3-axis vibration meter reduces the chance of underestimating or misinterpreting the severity of vibration.

- A 3-axis digital vibration meter collects all necessary data in one measurement session, significantly reducing the time needed for inspection and improving consistency.

- The multidimensional data helps in detecting anomalies early, tracking trends over time, and avoiding unexpected machinery failures, thereby reducing downtime and repair costs.

Portable and Easy to Carry

- A compact, handheld vibration meter is typically user-friendly, often designed with intuitive interfaces and minimal training requirements.

- Portability increases the flexibility of the vibration meter by allowing its use in various environments, from factory floors and construction sites to field surveys and laboratory tests.

- Portability enables quick inspections and diagnostics. Technicians can immediately respond to issues without having to transport equipment or wait for measurements to be taken in a lab environment. This rapid accessibility is crucial in time-sensitive environments such as manufacturing plants or construction sites.

Applications

SISCO 3-axis digital vibration meter measures vibrations along the single-axis X, Y, and Z or 3-axis XYZ, providing comprehensive data on vibrational movement. It is widely used in industrial maintenance, such as in aerospace, to monitor the condition of machinery, helping detect imbalances, before they lead to breakdowns. This kind of hand held vibration meter also plays a crucial role in product testing, ensuring that automotive components can withstand vibrations during transport or usage.

Aerospace

Machine Manufacturing

Railway Transportation

Automobile Industry

| Model | SISCO-VIBRO-VM260D |

| Vibration Sensor | 3-Axis piezoelectric accelerometer |

| Axial Vibration | Any one axis of X, Y, Z or 3 axes of XYZ |

| Accuracy | ±5%+2 digits |

| Measurement Range | Displacement: 0.001-4.000mm equivalent peak-peak / 0.04-160.0 mil |

| Velocity: 0.01-400.0 mm/s true RMS / 0.000-16.00 inch/s | |

| Acceleration: 0.1-400.0 m/s equivalent peak / 0.3-1312 ft/s / 0.0-40g | |

| Frequency Range | Displacement: 10Hz~1kHz |

| Velocity: 10Hz~1kHz | |

| Acceleration: 10Hz~10kHz | |

| Operating Conditions | Temperature: 0~50 ℃ |

| Humidity: below 95% RH | |

| Analogue Output | AC output 0~2.0V peak full scale (load resistance: above 10k) |

| Standard Accessories | Host/ magnetic suction seat/ probe (cone)/ probe (spherical)/ piezoelectric sensor/ carrying case/ manual |

| Optional Accessories | Headphones for use as electronic stethoscope/ cable and software for RS232C or USB/ Bluetooth |

| Power Supply | 4x1.5V AA battery (product not include battery) |

| Size | 140x77x32mm |

| Net Weight | About 1kg |

Q1: What is a digital vibration meter?

A1: A digital vibration meter is a handheld or portable device used to measure and analyze vibrations in machinery, equipment, or structures. It detects vibration levels using sensors like accelerometers and displays the results digitally. These meters help identify mechanical imbalances, misalignments, or bearing faults, enabling predictive maintenance and reducing equipment downtime.

Q2: How to set coordinate axis in a 3-axis vibration meter?

A2: There are 4 choices of X, Y, Z, XYZ in a 3-axis handheld vibration meter. Any one coordinate axis of X or Y or Z with 3 parameters of velocity, acceleration and displacement showing on one display can be selected. Or 3-axis of X-Y-Z with any one parameter of velocity or acceleration or displacement can be selected. The currently selected coordinate axis is shown on the meter's LCD. Every time to press the X / Y/ Z / XYZ key, the selected axis is changed. Please pay attention to the axes marked on the 3-dimensional sensor.

Q3: What are the advantages of using a 3-axis digital vibration meter?

A3: A 3-axis digital vibration meter offers precise and comprehensive vibration analysis by measuring in three perpendicular directions simultaneously—X, Y, Z or XYZ. This enables accurate detection of vibration magnitude and direction, essential for diagnosing machinery issues. Its digital display enhances readability and data interpretation. Allowing trend analysis and predictive maintenance. It improves efficiency by reducing the need for repositioning during measurements. Compact and user-friendly, it suits field and industrial applications.

Tips: How to maintain a 3-axis digital vibration tester?

To maintain a 3-axis digital vibration tester, store it in a clean, dry environment to prevent moisture and dust damage. Regularly inspect the sensor and cables for wear or damage. Avoid dropping or subjecting the meter to excessive force. Clean the device gently using a soft, dry cloth.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.