Portable digital vibration meter is an idea tester for measuring vibration. The bearing vibration tester supports different vibration frequency options, which can quickly detect defects in motors, fans, pumps, compressors and machine tools.

Features

- Digital vibration meter has a large LCD for visual display of measured values and measurement status.

- It is available with acceleration, velocity and displacement measurements.

- Bearing vibration meter has a high-sensitivity probe for accurate measurement.

- Equipped with a long probe and a short probe, for measurement in various places.

- The vibration tester features low battery indication, auto power-off, LCD backlight max value display, USB communication, data hold and data storage.

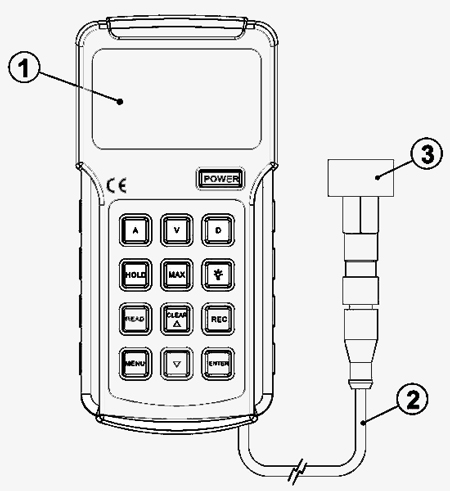

Handheld digital vibration meter details

- ① LCD

- ② Sensor cable

- ③ Probe (replaceable long probe, short probe and magnetic chuck)

- POWER: Power on/off

- A: Acceleration measurement

- V: Velocity measurement

- D: Displacement measurement

- HOLD: Hold data

- MAX: Display max value

- Light: Tum on/off the backlight

- READ: View recorded data

- CLEAR/▲: Clear recorded data; data up, USB communication, auto power off and autosave interval setting

- REC: Data storage MENU: Menu function setting

- ▼: Data down, USB communication, auto power off and autosave interval setting

- ENTER: Confirm

Applications

sisco portable digital vibration meter is a perfect tool for measuring vibration, which is widely applied to mechanical manufacturing, electric power, metallurgy, and other industrial measurements.

| Model | SISCO-VIBRO-UT315A |

| Acceleration measurement | 0.1~199 9m/s2 (peak value) |

| Velocity measurement | 0.01~19.99cm/s (true RMS) |

| Displacement measurement | 0.00-1.99mm (peak-to-peak value) |

| Measurement error | ±5%+2dgts |

| Frequency range (acceleration) | 10Hz~10kHz |

| Frequency range (velocity) | 10Hz~1kHz |

| Frequency range (displacement) | 10Hz~500Hz |

| LCD display | 2000-count display |

| Refresh cycle | 1s |

| Data storage | 1999 sets |

| Power supply | 9V 6F22 |

| LCD backlight off | Press the backlight button to turn off |

| Auto power off | After about 10 minutes of no operation |

| Battery life | Zn-mn battery: About 3 hours of continuous use, Alkaline battery: About 8 hours of continuous use |

| Operating temperature | 0~50°C |

| Operating humidity | 80%RH (no condensation) |

| Storage temperature | -20°C~60°C |

| Battery level indication | 4-level battery indication |

| Dimensions | 166mm*80mm*30mm |

| Weight | 395g |

| Altitude | 2000m |

| Safety standard | CE certification: EN61326-1 2013 |

Q1: What is a vibration meter?

A1: Vibration meter is used to directly indicate the peak, peak-to-peak, mean value or root mean square value of vibration quantity such as displacement, velocity, acceleration and derivative of acceleration. The main parts of this vibration tester are integral differential circuit, amplifier circuit, voltage detector and meter head. The integral and differential circuit is used to complete the integral and differential operation between the above vibration quantities. Generally, the integral and differential operational amplifier can be used, and the low-pass filter and high-pass filter can be used respectively to complete the integral and differential operation. However, attention should be paid to their application frequency range when using such instruments for calculation. The vibration meter allows one to obtain only the total intensity of the vibration (the vibration level) and no other information.

Q2: How does a vibration meter work?

A2: Mechanical vibration is generally measured by electrical measurement. The basic principle of vibration meter is to convert mechanical quantity into electric quantity through vibration sensor, and then measure and analyze the electric quantity, so as to obtain various parameter values of the measured mechanical vibration quantity. In the field vibration test of turbine generator set, the vibration sensor commonly used in vibration tester has three types, they are eddy current non-contact displacement sensor to measure the relative vibration of rotating shaft, inertia speed sensor and voltage acceleration sensor to measure the vibration of bearing seat and foundation, cylinder structure and so on. In addition, in order to measure the absolute vibration of a rotating shaft, a composite sensor consisting of an eddy current non-contact displacement sensor and an inertial velocity sensor is often used.

Q3: What does a vibration meter do?

A3: The vibration meter can easily measure the vibration parameters such as vibration, acceleration and velocity. The vibration tester can also be used to reliably and quantitatively evaluate the vibrations of rotating and reciprocating machines. It is widely used in mechanical design and manufacture, military, electric power, equipment management, transportation and environmental protection departments etc. The vibration meter provides these fields great convenience for on-line inspection and monitoring of machine equipment faults and aging signals, product quality control, vibration test measurement and vibration control.

Tips: What are the types of vibration meter?

- Piezoelectric vibration meter

Piezoelectric vibration meter is characterized by high natural frequency, wide frequency range, small volume, light weight and little influence on the measured object, so it has been widely used in the measurement of vibration acceleration. The internal resistance of piezoelectric vibration tester is high, and the cable connected with the amplifier is easy to introduce interference, so it is hoped that the cable should be as short as possible and shielding should be considered, and the preamplifier should be placed near the sensor as much as possible. Most amplifiers used to amplify the electrical signals generated by piezoelectric sensors are now charge amplifiers. - Mechanical vibration meter

It is by inserting a spring (or several springs) into the housing and installing a mass block of mass m underneath the spring. This also constitutes the mechanical resonance system. Usually mechanical resonant systems are damped. - Table frame vibration meter

Table frame vibration meter is fixed on the meter frame, the meter frame is fixed on the support isolated from the fan, and the measuring rod of the meter and the bearing box surface or other measuring parts can be measured. This kind of vibration meter does not need to make any other machine parts, simple structure, and can measure any direction of vibration. The disadvantage of the table frame vibrator is that the support is not easy to isolate from the vibration, and the accuracy is poor. - Sponge vibration meter

The sponge vibration meter is made by fixing the measuring rod sleeve of the micrometer on the heavy plate with a fixed screw and padding the sponge ring. It is characterized by simple structure but poor accuracy, and can only measure the vibration in the vertical direction. - Handheld vibration meter

Handheld vibration meter is simple structure, which can measure the vibration in any direction, measuring speed dig =1000 ~ 2000 RPM, / time, the error is small.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.