Buy a bike spoke tension meter online, the spoke tension meter measures the spoke tension on any kind of spoke, it is for anyone building or truing wheels, diagnosing wheel problems, or assembling new bikes. It’s a tool that belongs on every workbench.

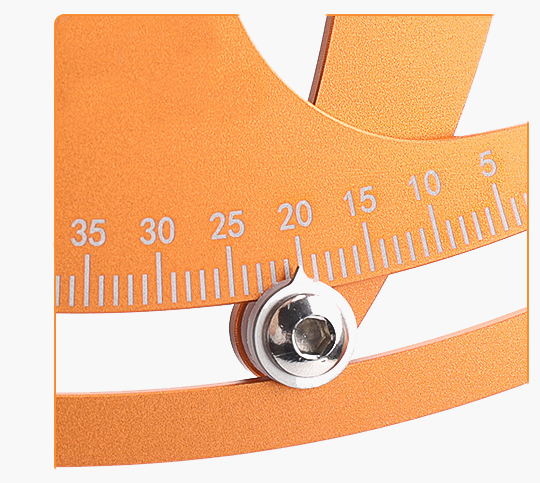

Stainless steel screw

- High strength, not easy to rust

- Stainless Steel Resilient Components

Dial design

- Digital clarity, measurement standards

- Easy to read

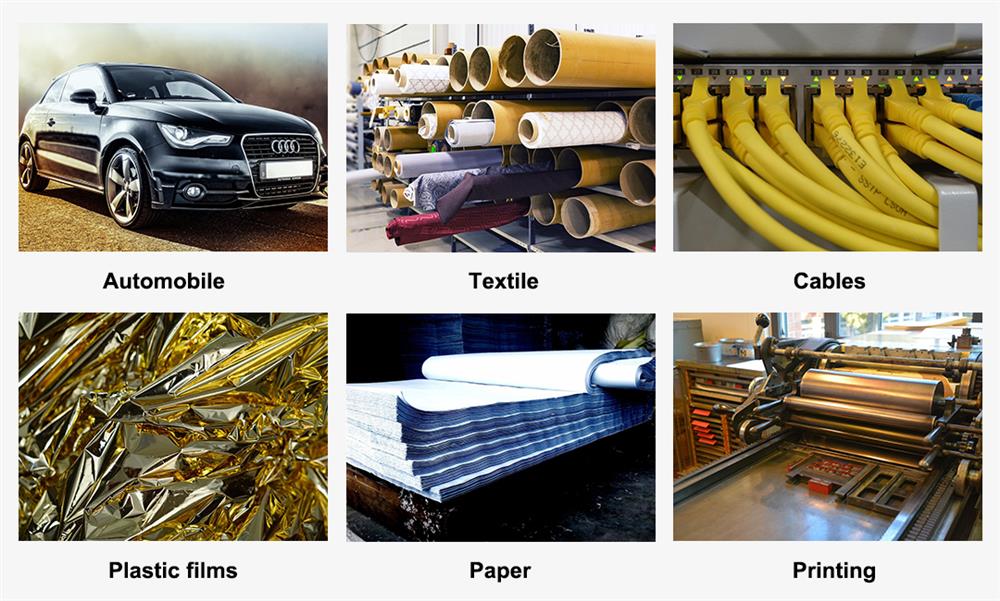

Applications

Tension meters are instruments that measure tension in cable, fiber, belts and webs, or sheets. sisco tension meter mainly used in belt tension measurement can also be applied to measure the tension of objects such as tapes, and wires. Widely applied in industries of automobile, textile, cables, wires, plastic films, paper, and printing.

- Model: SISCO-STT-01

- Material: Main body aluminum alloy

- Color: Orange

- Weight: 200g

- Size: 191*122mm

- Treatment: Hard anodized oxidation, non-fading

Dimension

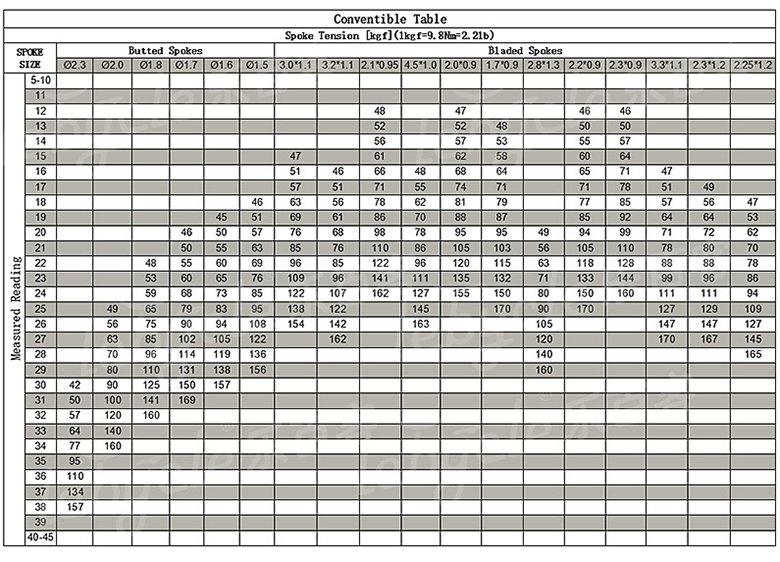

Bike Spoke Tension Meter Convertible Table

Q1: What is a tension meter?

A1: A tension meter is a device used to measure tension in wires, cables, textiles, Mechanical belts, and more. Meters commonly use a 3-roller system where the material travels through the rollers causing deflection in the center roller that is connected to an analog indicator or load cell on digital models. Single-roll tension sensors and sonic tension meters are other types of tension meters. Tension may also be inferred from the frequency of vibration of the material under stress by solving the "Vibrating String Equation". Tension meters are available as handheld devices or as equipment for fixed installations. These are basically necessary to build up a tension-controlled closed loop.

Q2: What is the purpose of the tension meter?

A2: A tension meter is a device used to measure tension in wires, cables, textiles, Mechanical belts, and more. Meters commonly use a 3-roller system where the material travels through the rollers causing deflection in the center roller that is connected to an analog indicator or load cell on digital models.

Q3: How does a tension meter work?

A3: Tension meters measure the dynamic tension in a moving yarn and regulate the tension of the yarn on a winding machine. Tension sensors are dynamic tension devices. The piezoelectric element mounted on a flexible beam is the most important part of tension sensors.

Tips: What tension should my spokes be?

A spoke tension meter belongs to the field of bicycles. Most rims have suggested ranges from 100 to 120 Kilograms-force, or 980 to 1177 Newtons. This is assuming there is no pressure in the tire. Though not super precise, squeezing is still a more accurate technique for judging spoke tension than feeling the amount of effort it takes to turn a spoke nipple.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.