The 0-30 Pa differential pressure gauge is a high-precision instrument designed for measuring very low-pressure differences in various applications. The diff pressure gauge is ideal for clean rooms, HVAC systems, pharmaceutical environments, and other critical settings, this gauge ensures accurate and reliable pressure monitoring.

Precision cast all-aluminum shell

- The dp gauge is sprayed with imported plastic powder, which has suitable thickness and drying temperature, high hardness, is not easy to foam, and is not easy to produce aluminum rust.

- Drop test from a height of one meter, no damage to the surface.

High strength plastic PC cover

- The cover of diff pressure gauge with good permeability, clear viewing angle.

- Excellent strength and high safety protection.

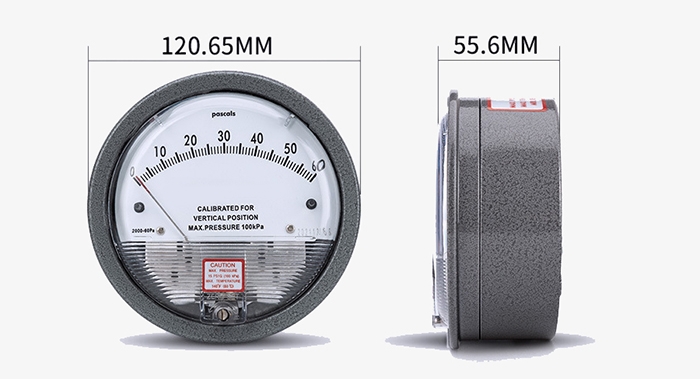

Dimension

Applications

SISCO differential pressure gauge is essential in various industries for monitoring filter conditions, measuring flow rates, determining liquid levels in tanks, ensuring pump efficiency, maintaining clean room pressure, assessing HVAC system performance, and safeguarding hydraulic, boiler, and environmental systems, as well as in specialized applications like pharmaceutical factories, purified air conditioners, microelectronics environments, and blower pressure measurements, all by accurately measuring the pressure difference between two points to ensure optimal operation, safety, and compliance with regulations.

Purify Air Conditioner

Microelectronics

Blower Pressure Measurement

Pharmaceutical Factory

| Model | SISCO-DPG-30 |

| Measuring Range | 0~30Pa |

| Accuracy | 21℃ full scale ±4% |

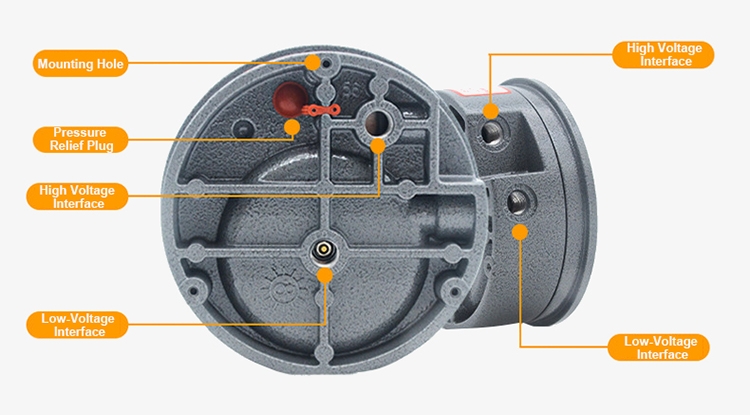

| Use interface | 1/8 inner tooth normal temperature and pressure dual high and low pressure interface (back) |

| Overvoltage | The rubber overpressure plug was flushed open at about 172kPa. |

| Size | 120.65*55.6mm |

| Ambient Temperature | -7°C~ 60°C |

| Material | Die cast aluminum |

DP Gauge Structure

Q1: Can a differential pressure gauge measure both positive and negative pressure differences?

A1: Yes, a differential pressure gauge can measure both positive and negative pressure differences between two points. It is designed to indicate the difference regardless of which side has the higher pressure.

Q2: Can a differential pressure gauge be used in high-temperature environments?

A2: It depends on the specific gauge and its construction materials. Some diff pressure gauges are designed to withstand high temperatures, but it is important to check the manufacturer's specifications to ensure suitability for high-temperature applications.

Q3: Can I calibrate a differential pressure gauge myself?

A3: Yes, you can calibrate a differential pressure gauge if you have the proper equipment and follow the correct procedures. Calibration should be done using a known reference standard, and the process may vary depending on the gauge type. For critical applications, professional calibration services are recommended.

Tips: What factors should I consider when selecting a differential pressure gauge?

By considering these factors, you can select a differential pressure gauge that best fits your specific needs and ensures reliable and accurate measurements for your application.

- Pressure Range: Ensure the gauge can measure the expected differential pressures in your system. Choose a gauge with a range that covers your application's maximum and minimum differential pressures.

- Accuracy: Depending on your application's requirements, select a gauge with the necessary accuracy. Higher accuracy gauges are essential for critical applications where precise measurements are vital.

- Media Compatibility: Consider the types of fluids or gases in your system. Ensure the materials of the gauge are compatible with the media to prevent corrosion, chemical reactions, or damage. Stainless steel, brass, and other specific materials are available for different media.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to dust, chemicals, or water. Choose a gauge designed to withstand these conditions. For example, some gauges are rated for high temperatures or have protective enclosures for harsh environments.

- Output and Compatibility: If you need to integrate the gauge with a digital monitoring or control system, choose one with the necessary output type, such as analog, digital, or 4-20mA signals. Ensure compatibility with your existing systems.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.