Digital rotational viscometer provides accurate and rapid viscosity measurement in range of 1 to 100,000 mPa·s, with rotor spindles 0#, 1#, 2#, 3#, 4# suitable for a variety of industrial and laboratory applications.

Features

- The digital rotational viscometer can measure the viscosity of a Newtonian liquid or the apparent viscosity of a non-Newtonian liquid.

- Adopt the advanced micro-computer drive technology and stepper motor, accurate and stable rotating speed.

- The horizontal display unit is at the front of the viscometer, convenient to adjust.

- The measuring range and viscosity value can be accurately display with resolution of 0.01mPa.s.

- With timing measurement function, it is practical for measuring the non-Newtonian liquid.

- With automatic scanning, the viscometer can automatically recommend a preferred combination of rotor and speed.

- The viscosity measurement range of the selected rotor and rotating speed is automatically displayed.

- With the printing interface, a micro-printer can be connected to print various data.

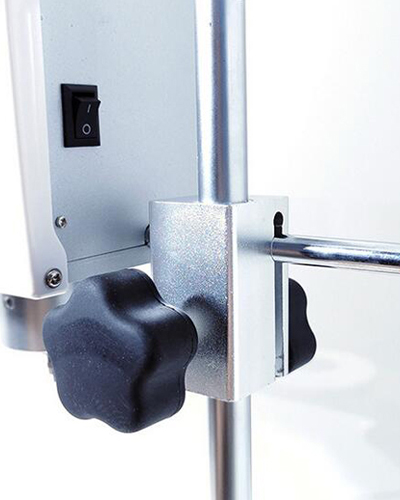

All metal lifting parts

- Digital rotary viscometer has all-metal lifting parts, high stability, strong and durable. The operating knob is covered with rubber, which is comfortable and labor-saving.

- Digital rotary viscometer uses a large number of high-quality aluminum-magnesium alloy, stainless steel and other materials, and is processed by high-precision processing equipment to ensure the reliability and accuracy of the whole machine.

- The whole lifting column and rack part are made of pure copper, and cooperate with the high-precision gear components in the lifting slider to provide the host with a stable and smooth operating experience.

Rich extension interface

The digital rotational viscometer has an external power supply, wide voltage input, which can be equipped with high-precision temperature sensor, PC data acquisition software, portable printer, etc.

Applications

sisco digital rotary viscometer is widely used in the manufacturing, scientific research institutes or laboratory for viscosity measurement of oils, greases, paints, coatings, pulp, textiles, food, pharmaceuticals, adhesives and cosmetics, etc.

| Model | SISCO-NDJ-5S |

| Measuring Range | 1* ~ 100,000 mPa·s |

| Rotating Speed (r/min) | 6/12/30/60 |

| Resolution | 0.01 mPa·s |

| Rotor | 1#, 2#, 3#, 4# (Standard, for measuring viscosity more than 10 mPa.s) 0# (Optional, for measuring the ultra-low viscosity less than 10 mPa.s) |

| Sample Consumption | (1# , 2# , 3#, 4# ): 250-400mL 0#: 21mL |

| Measuring Accuracy | ±2% (full range) |

| Repeatability | ±0.5% |

| Display | LCD display |

| Timing Measurement Function | Yes |

| Auto Scanning Function | Automatically recommending the optimal combination of the rotor and rotating speed according to the sample viscosity. |

| Measuring Range Display Function | Automatically displaying the maximum viscosity value measurable for the selected rotor and speed combination. |

| Data Output Interface | Yes |

| Power Supply | 100-240V, 50/60Hz |

| Net Weight | 7kg |

| Size | 300*300*450mm |

| Standard Packing List | Viscometer main machine Rotor 1#, 2#, 3#, 4# Rotor protective frame Triangular base and column Aluminum alloy carrying case Power adapter |

| Optional Accessories | Rotor 0#, Temperature probe, Software, Mini printer |

Note: * The rotor 0# is required when the measuring viscosity is lower than 10 mPa·s.

Q1: What is a viscometer?

A1: A viscometer is an instrument used to measure the viscosity of fluids (liquids and gases). Viscosity is a physical quantity that indicates the internal friction within the fluid when the fluid is flowing. It is the ability of the fluid to resist deformation. It is an important indicator used to identify some finished or semi-finished products. Viscosity varies from fluid to fluid and varies with temperature. There are mainly three types of capillary viscometers, rotational viscometers and falling ball viscometers.

Q2: What is the definition of viscosity?

A2: When a liquid is flowing, the property of internal friction between its molecules is called the viscosity of the liquid. The viscosity of the liquid is expressed by viscosity, which is a resistance factor used to characterize the properties of the liquid. The viscosity of insulating oil is the same as the viscosity of general liquid, that is, the internal friction of the liquid, that is, when the insulating oil moves relative to laminar flow under the action of external force. The properties of insulating oil molecules that generate internal frictional resistance. The greater the internal friction of the insulating oil, the greater the viscosity, the more difficult the flow, and the poorer heat dissipation performance.

Q3: What is a viscometer used for?

A3: Viscosity is an important physical parameter used to measure the ability of liquids to resist flow. Using a viscometer to measure the viscosity of a liquid is an important means of industrial process control, improving product quality, and saving and developing energy. It is closely related to the fields of petroleum, chemical, electric power, metallurgy and national defense. Status plays an important role.

Tips: How to use a viscometer?

- The viscometer must be kept level.

- Avoid generating air bubbles when the rotor is put into the sample, otherwise the measured viscosity value will decrease. The way to avoid it is to put the rotor into the sample at an angle, and then install the rotor. The rotor cannot touch the wall and bottom of the cup. The sample to be measured must not exceed the specified scale.

- When measuring different samples, the rotor must be kept clean and dry. If the rotor has other samples or residual water after cleaning, it will affect the accuracy of the measurement.

- The maximum acidity (PH) should not exceed 2. If the acidity is too large, a special rotor should be used. When using ULA, the sample volume should be determined (only 16ml).

- Select the viscosity standard solution according to the measured viscosity range, and verify the instrument before each use of the viscometer, or check it regularly to ensure the accuracy of the measurement. It can provide Newtonian fluids in each viscosity range Properties of silicone oil or oil standard, the accuracy is ±1%, and the recommended use period of the viscosity standard solution is one year from the opening of the package.

- When connecting the rotor, use your left hand to gently hold and hold the mandrel (on the main unit), and rotate the rotor with your right hand. This operation is to protect the mandrel and hairspring in the body, which can prolong the service life of the viscometer.

- The value should be taken when the value is relatively stable, otherwise there will be a large error in the obtained value.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.