Fixed ammonia gas detector is a kind of 24h continuously wall mounted type gas detector, with alarm light, data display and high/low alarm, fast response, high precision and good stability. Powered by 4-20mA and RS485 signal output, suitable for different kinds of situations.

Anti-magnetic interference

- The fixed ammonia gas detector can resist the strong magnetic interference of 15V/meter.

- In areas with dense magnetic products or dense electronic products, such as tunnels, mines, confined spaces, etc., the data is guaranteed to be stable and reliable.

Using high-precision sensors

- The fixed online NH3 gas detector is equipped with an infrared remote control as standard, which can realize the functions of alarm point setting, zero point calibration, and address modification without opening the cover.

- Compatible with various control alarms, PLC, DCS and other control systems to realize remote monitoring.

Variety of installation methods

- Wall mounted type, installed on the wall directly, real time monitoring.

- Piping type, installed on the pipeline, monitoring the gas concentration inside.

- Flow type, connected with external sampling pump and tube, measure the gas concentration in enclosed space.

Applications

Fixed ammonia NH3 online gas detector can detect harmful gas of furniture, flooring, wallpaper, paint and other items, which is widely used in biological pharmaceutical factories, green home, livestock and poultry breeding, greenhouse cultivation, warehousing and logistics, brewing and fermentation, agricultural production, etc.

| Model | GD300-NH3 |

| Detection Principle | Electrochemistry |

| Gas | Ammonia (NH3) |

| Range (Optional) | 0 to 50 ppm, 0 to 100 ppm, 0 to 200 ppm, 0 to 500 ppm, 0-1000 ppm, 0 to 2000ppm, 0 to 5000ppm |

| Calibration Kit | Gas pressure regulator (calibration gas cylinder NOT included) |

| Resolution | 0.01 ppm (0-50 ppm), 0.1 ppm (0-100/200ppm), 1 ppm (0-500/1000/2000/5000 ppm) |

| Accuracy | ≤±3% F.S. |

| Responce Time | ≤10s |

| Repeatability | ≤±1% |

| Recovery Time | ≤10s |

| Linearity Error | ≤±1% |

| Zero Shift | ≤±1% (F.S./year) |

| Signal Output (Optional) | 4-20mA and RS485 Relay output: one group of relay output (1NO+1NC, 24V 100mA) for one alarm (default), or two groups of relay output (2NO+2NC, 24V 100mA) for high/low alarm (optional). |

| Alarms | Sound, light |

| Display | High light nixie tube display |

| Installation | Wall-mounted, piping type, flow-type (according to the detected environment) |

| Connection | Power connection type: G1/2 male thread explosion-proof flexible pipe Pipe-mounted type: M45*P2.0 |

| Operating Time | 24h |

| Explosion-proof Grade | Ⅱ 2G Ex ia Ⅱ CT4 Ga |

| Protection Grade | IP65 |

| Certification | CE, ATEX (Standard: EN IEC 60079-0:2018, EN 60079-1:2014) |

| Working Voltage | 12-36V DC |

| Case Material | Die-casting aluminum housing |

| Operating Temperature | -20℃~50℃ |

| Operating Humidity | 0~95%RH (non-condensing) |

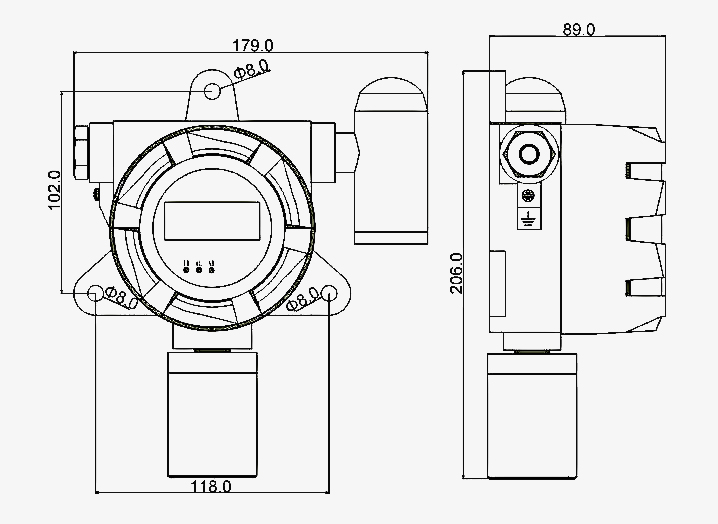

| Dimension | 206*179*90mm |

| Weight | ≤1.6kg |

| Accessories | Power adapter: Input 100-240VAC 50/60Hz, Output 24VDC 1A (Optional USA plug, Europe plug or UK plug) |

Note: To measure confined spaces such as pipelines, please contact us and inform the detailed conditions of use.

Fixed Ammonia (NH3) Gas Detector Dimension (Unit: mm)

Gas Detector Catalog & User Manual

SISCO Gas Detector Catalogue

SISCO Gas Detector Catalogue SISCO GD200 Portable Gas Detector User Manual

SISCO GD200 Portable Gas Detector User Manual SISCO GD300 Online Fixed Gas Detector User Manual

SISCO GD300 Online Fixed Gas Detector User Manual SISCO GD400 Explosion Proof Portable Gas Detector User Manual

SISCO GD400 Explosion Proof Portable Gas Detector User Manual SISCO GD500 Handheld Multi Gas Detector User Manual

SISCO GD500 Handheld Multi Gas Detector User Manual SISCO GD600 Multi Gas Analyzers User Manual

SISCO GD600 Multi Gas Analyzers User Manual SISCO Gas Detector Communication Protocol V1.0

SISCO Gas Detector Communication Protocol V1.0 SISCO Single Stage Pressure Regulator User Manual

SISCO Single Stage Pressure Regulator User Manual SISCO Gas Detector Data Downloading Operation Instruction

SISCO Gas Detector Data Downloading Operation Instruction

Q1: What is a fixed gas detector?

A1: The fixed gas detector is composed of sensors and transmitters, and is installed at the detection site. The secondary instrument consisting of circuit, power supply and display and alarm device is installed in a safe place, which is convenient for staff to monitor. In industrial installations and production processes, fixed gas detectors are generally used, because fixed gas detectors can be installed at specific detection points to detect specific gas leaks.

Q2: What does a gas detector detect?

A2: Combustible gases: Natural gas (methane), liquefied gas, coal gas (hydrogen), acetylene, pentane, alkynes, acetone, toluene, alcohols, hydrocarbons, light oil, etc.

Toxic gases: Carbon monoxide, hydrogen sulfide, ammonia, chlorine, oxygen, phosphine, sulfur dioxide, hydrogen chloride, chlorine dioxide and other toxic and harmful gases.

Q3: Difference between fixed gas detector and portable gas detector

A3: The biggest advantage of fixed gas detectors is 24-hour uninterrupted measurement. As long as the power is turned on, the fixed gas detector is in normal detection work. Portable gas detectors are usually used in confined spaces and confined spaces, but the gas environment in these spaces is usually very complex, and there will be situations such as lack of oxygen and high concentrations of harmful gases.

Tips: What are the installation requirements for fixed gas detectors?

The fixed gas detector is generally fixed on the wall, but different heights will affect the accuracy of the gas detector, which is a major focus of installing it.

- The density of the gas to be measured

When installing a fixed gas detector, you should first consider the density of the gas to be measured. We all know that the density of various gases is different from the density of air. If the density of the gas to be tested is greater than that of air, it should be installed below the gas released; if it is less than air, it should be installed above the leakage of the gas to be tested, so that the gas can be detected faster and more accurately. - Annual inspection

To ensure its detection accuracy, gas detectors should be calibrated at least once a year. - Distance between controller and fixed gas detector

The controller and the fixed gas detector cannot be placed together. The gas detector is installed in a dangerous area where gas is easy to leak and accumulate, while the controller is installed in a safe area that is easy to see.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.