sisco ultrasonic thickness gauge is a portable, durable and high-accuracy ultrasonic thickness measurement, widely used in the fields such as manufacturing, metal processing, and chemistry. Digital ultrasonic thickness tester provides 1mm~100mm measuring range with standard probe and high resolution 0.01mm or 0.001 inches, material velocity range 1000~9999m/s (0.0394 to 0.3937in/μs) and backlit LCD display.

Handheld ultrasonic thickness gauge can directly measure the material's thickness.

- 0.01mm or 0.001 inches resolution

- 128*64 pixels display with backlight

- 500 thickness readings can be stored

- Hi-Low alarm setting

- Minimum thickness capture

- V-sound path correction

- Bult-in 7 types of transducer compensation line

- Through paint/coating function (SISCO-UM-2D only)

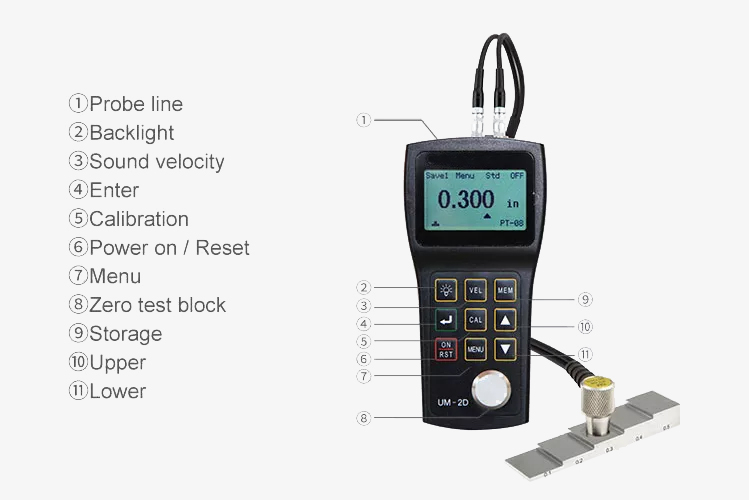

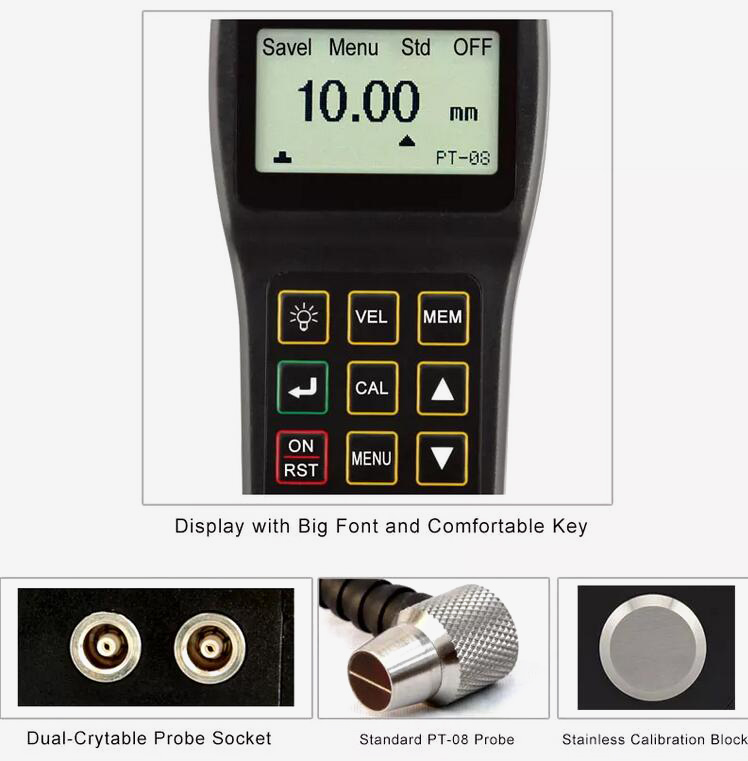

Details

Applications

sisco handheld ultrasonic thickness gauge is used to measure metallic and non-metallic materials, including plastic, steel, PVC and glass plates and pipes. It can be widely used in manufacturing, metal processing and other fields, and can also perform corrosion and thinning detection on various pipes and pressure vessels in manufacturing facilities.

| Model | SISCO-UM-2 | SISCO-UM-2D |

| Display Type | 128 ×64 dot-matrix LCD screen with EL backlight | |

| Operating Principle | P-E (pulse-echo) with the dual-crystal probe | P-E (pulse-echo), E-E (Echo-Echo) with the dual-crystal probe |

| Total Measuring Range | 0.8mm-300mm, depending on the material and probe | |

| Measuring Range in Standard Mode | Standard probe PT-08: 0.8mm-100mm | |

| Measuring Range in Thru Coating Mode | N/A | 3-20mm with PT-08 probe |

| Measuring Limits of Tube (Steel) | Φ20mm×3.0mm (PT-08 probe) The measuring error is up to ± 0.1mm. |

|

| Measuring Error | Lower limit to 10mm: ±0.05mm 10mm to upper limit: ±(0.5%H+0.01)mm Note: H is the actual thickness of the tested material |

|

| Repeatability | 0.05mm | |

| Display Resolution | 0.01mm or 0.001 inch | |

| Units | Inch or Millimeter | |

| Calibration Method | Zero calibration, Two-point calibration | |

| V-Path Correction | Automatic | |

| Update Rate | 4Hz | |

| Material Velocity Range | 1000~9999m/s (0.0394 to 0.3937in/μs) | |

| Memory Function | 5 arrays are divided to store 500 thickness values | |

| Minimum Value Checking | Taking the probe to move along the surface of the tested material, the gauge is able to find the thinnest point automatically. | |

| Warning Function | If the measured value exceeds the pre-set thickness limit, the gauge will sound an alarm. | |

| Velocity Storage | Can store the velocities of 5 different materials in total | |

| Languages | English and Chinese | |

| Communication Port (Optional) | USB port or Serial RS 232 port | |

| Application Software (Optional) | UmView Software for data transmission, storage, analysis and document editing | |

| Power Supply | Two 1.5V AA alkaline batteries (Alarm for low battery voltage) | |

| Operating Time | Up to 200 hours with alkaline batteries (without backlight) | |

| Instrument Shut-off | AUTO OFF after 5 minutes of no operation | |

| Operating Temperature | -10℃ ~ +50℃ | |

| Size | 149mm×73mm×32mm (H×W×D) | |

| Weight | 210g including batteries | |

Note:

* Standard Packing List

Ultrasonic Thickness Gauge × 1, Standard Probe × 1, Battery × 2, Couplant × 1, Carrying Case × 1, Operating Manual × 1

(Kindly Reminder: Battery and Couplant are Not Included if Shipped By Air.)

| Model | PT08 | PT06 | PT04 | ZT12 | GT12 |

| Type | Standard | Small Tube | Fingertipe | Cast iron | High-Temperature |

| Frequency | 5MHz | 7.5MHz | 10MHz | 2MHz | 5MHz |

| Diameter | 11mm | 8mm | 6mm | 17mm | 15mm |

| Measuring Range | 0.8~100mm | 0.8~30mm | 0.7~12mm | 4.0~508mm | 4.0~80mm |

| Allowable Temperature | -10℃ ~ 70℃ | -10℃ ~ 70℃ | -10℃ ~ 70℃ | -10℃ ~ 70℃ | -20℃ ~ 450℃ |

| Picture |  |

|

|

|

|

Function Comparison

| Model | SISCO-UM-1 | SISCO-UM-1D | SISCO-UM-2 | SISCO-UM-2D |

| Operating Principle | P-E (pulse-echo) | P-E (pulse-echo), E-E (Echo-Echo) | P-E (pulse-echo) | P-E (pulse-echo), E-E (Echo-Echo) |

| Measuring Range in Standard Mode | 0.8mm-300mm, depending on the material and probe | |||

| Measuring Range in Thru Coating Mode | N/A | 3-20mm | N/A | 3-20mm |

| Measuring Resolution | 0.1mm, 0.001 inch | 0.1mm, 0.001 inch | 0.01mm, 0.0001 inch | 0.01mm, 0.0001 inch |

| Probe Compensation Line | 1 built-in probe compensation line | 1 built-in probe compensation line | 7 built-in probe compensation line | 7 built-in probe compensation line |

| Data Logger | Y | Y | Y | Y |

Q1: What is an ultrasonic thickness gauge?

The ultrasonic thickness gauge is improved based on the principle of ultrasonic measurement. It can measure the thickness of metals and other materials and can measure the sound speed of the material. The sisco ultrasonic thickness gauge is a portable thickness meter that can measure the thickness of various pipes and pressure vessels in production equipment, as well as accurately measure various sheets and machined parts.

Q2: How does an ultrasonic thickness gauge work?

sisco ultrasonic thickness gauge offers through-coating thickness measuring capability. It measures the thickness of an object by precisely calculating the times the probe sends an ultrasonic pulse to the object and passes through the object until the probe receives the reflection from the boundary. The ultrasonic pipe thickness gauge adopts the most advanced microprocessor and ultrasonic technology and has the characteristics of zero drift, reliable and stable reading, and no need for zero calibration. You can now test painted objects without removing paint or correcting paint thickness.

Q3: 4 Measurement methods of ultrasound thickness gauge

- Single-point measurement method: It means that the ultrasound thickness gauge is used to measure any point of the measured material with a probe, and the display value is the thickness value.

- Two-point measurement method: The ultrasound thickness meter is used to make two measurements at the same point of the measured material with a probe. In the second measurement, the probe's split surface is 90 degrees, and the smaller value in the two measurements is the thickness value.

- Multi-point measurement method: When the measurement value is unstable, take a measuring point as the center and make multiple measurements in a circle with a diameter of about 30 mm. The minimum value is the thickness value.

- Continuous measurement method: It uses a single-point measurement method to measure continuously along a designated line with an interval of not less than 5 mm. The minimum value is the thickness value.

Tips: Why do ultrasonic thickness gauges need couplant?

In order to improve the sound energy transmission between the probe of ultrasonic thickness gauge and the workpiece, a thin layer of liquid applied between the probe and the detection surface is called a couplant.

When there is a layer of air between the probe of ultrasonic thickness gauge and the workpiece, the reflectivity of the ultrasonic wave is almost 100%. Even a thin layer of air can prevent the ultrasonic wave from entering the workpiece. Therefore, it is very important to remove the air between the probe and the workpiece. The coupling agent can fill the air gap between the probe and the workpiece, so that ultrasound can be transmitted to the workpiece, which is the main purpose of using the couplant. In addition, the couplant also has a lubrication effect, which can reduce the friction between the probe of ultrasonic thickness gauge and the workpiece, prevent the workpiece surface from wearing the probe, and make the probe easy to move.

According to the surface condition and acoustic impedance of the workpiece to be tested, the coupling agents without bubbles and suitable viscosity should be selected, such as glycerin, oil, silica gel, water glass and paste, high temperature coupling agent, etc. If the surface of the workpiece is rough, the thicker coupling agent should be chosen. The coupling agents specially used for thickness measurement can also be used. In practical use, it is necessary to keep the coupling agent clean, not to make it stained, or it will affect the accuracy of the measurement of ultrasonic thickness gauge.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.