Buy explosion-proof sound level meter online, protection level IP44, measurement range from 28 dB(A) to 133 dB(A), widely used in environmental protection, factory enterprises, scientific research and teaching fields, to complete the environmental noise measurement, machinery and equipment noise measurement and building acoustic measurement, etc.

Multifunctional sound level meter

- In modular design, the user can choose total value integration, statistical analysis, 1/1 0CT analysis, GPS, Bluetooth, and other functions as needed.

- A variety of start-up methods can be set to automatically switch on and off at regular intervals.

Digital Signal Processing Technology

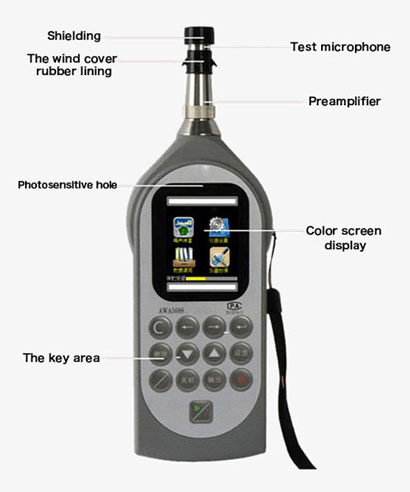

- Adopting digital signal processing technology, it can complete the measurement of various indicators such as A, C, Z three kinds of frequency counting F, S. I three kinds of time counting.

- Adopt LCD display, humanized interface, rich content, low power consumption.

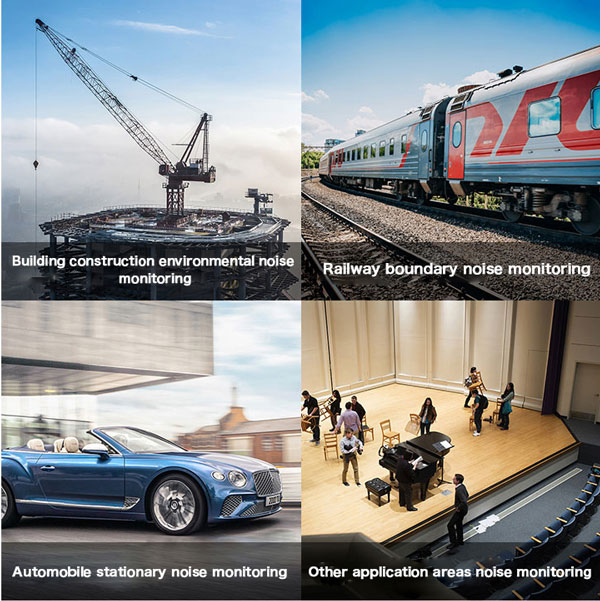

Applications

sisco multifunctional sound level can measure a variety of evaluation indicators at the same time, modular design, users can purchase the corresponding modules according to needs. The instrument is mainly used in industrial machinery and product noise measurement, environmental noise measurement, workplace noise measurement, airport noise measurement, and Hall acoustic characteristics measurement, etc.

| Model | SISCO-SLM-AWA-5688 |

| Microphone Model | AWA14421 |

| Measuring Range | 28 dB(A)~133 dB(A) |

| Frequency Range | 20 Hz~12.5 kHz |

| Frequency Weighting | Parallel (simultaneous) A, C, Z for each channel |

| Time Weighting | Parallel (simultaneous) F, S, I, Peak for each channel |

| Monitor | 2.6-inch color screen display, resolution 240×320, brightness adjustable |

| Output Interface | AC, DC, RS 232, USB |

| Main Measurement Index | Lxyi, Lxyp, Lxeq, Lxmax, Lxmin, LxN, SD, SEL, LCpeak |

| 24-Hour Automatic Monitoring | Measure 1 time per hour, in addition to statistical analysis of all measurement indicators, there are also Ld, Ln, Ldn |

| Data Storage Function | Standard 3 MB |

| Filter selection | 1/1 OCT center frequency: 31.5 Hz~8 kHz |

| Other Optional Features | Bluetooth, recording, GPS positioning |

| Dimension | 240mm x 80mm x 30mm |

| Explosion-Proof Type | Intrinsically safe |

| Shell Protection Level | IP44 |

| Power Supply | 4 LR6 (No. 5) alkaline batteries; DC 5 V±0.5 V, 1 A external power supply can also be used |

| Weight | 2.5 kg |

| Operating Temperature | -40 ℃~40 ℃ |

| Warranty | 12 Months |

Q1: What is a noise detector?

A1: Noise tester is an instrument used for noise detection and testing in public places such as work sites and squares. Factory noise monitoring Noise pollution is one of the environmental pollutions that have a greater impact. Higher decibel noise can even cause serious damage to people's eardrums and cause deafness. The application of the noise tester can provide the decibel that the noise reaches in order to take relevant measures to control and reduce the noise. The measurement unit of the sound level is decibels. The professional noise tester has a highly sensitive sensor, high accuracy, and a wide range of applications. It can be widely used for noise measurement in various environments. Sound level measuring instrument, collectively referred to as sound level meter.

Q2: Sound level meter working principle

A2: The sound level meter uses a microphone to convert the sound into an electrical signal, and then a preamplifier converts the impedance to match the microphone with the attenuator. The amplifier adds the output signal to the weighting network, performs frequency weighting on the signal (or an external filter), and then amplifies the signal to a certain amplitude through the attenuator and amplifier, and sends it to the effective value detector (or external press Level recorder), give the value of the noise level on the indicator head.

Q3: How big is the decibel scale?

A3: Sound is measured in decibels (dB). Whispering is about 30 decibels, normal conversation is about 60 decibels, and motorcycle engines run at about 95 decibels. Noise above 70 decibels for long periods of time may begin to damage your hearing. Loud noises above 120 dB can cause immediate damage to your ears.

Tips: Why should the sound level meter be calibrated before use?

- Sound level meter measurement is through the sound signal (sound wave) caused by the air vibration wave to the sound level meter front microphone (microphone head) metal diaphragm vibration wave signal into electrical signals, and then by the counting network, circuit operation amplification, by digital or electric meter way to display the noise decibel value.

- The quality of air is unstable, such as the temperature, humidity and atmospheric pressure of air will change at any time due to the influence of the environment and other factors, so to ensure the accuracy of the air vibration wave signal received by the microphone metal diaphragm, the sensitivity of the microphone should be adjusted accordingly.

- The process of adjusting the microphone sensitivity is to calibrate the sound level meter.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.