The taber abrasion tester evaluates wear resistance by rotating samples against weighted abrasive wheels. Ideal for testing materials like fabric, leather, glass, and plastic, it simulates real-world friction to measure material durability through precise weight loss after abrasion.

Durable Design with Precision Wear Testing

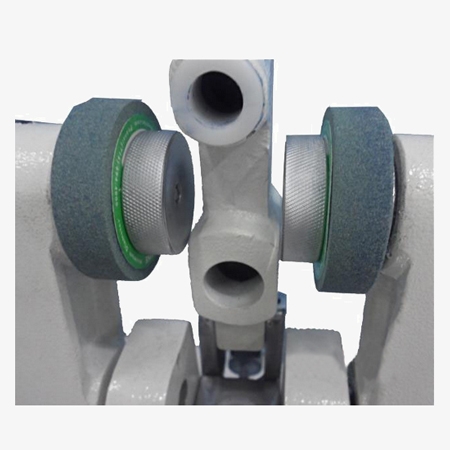

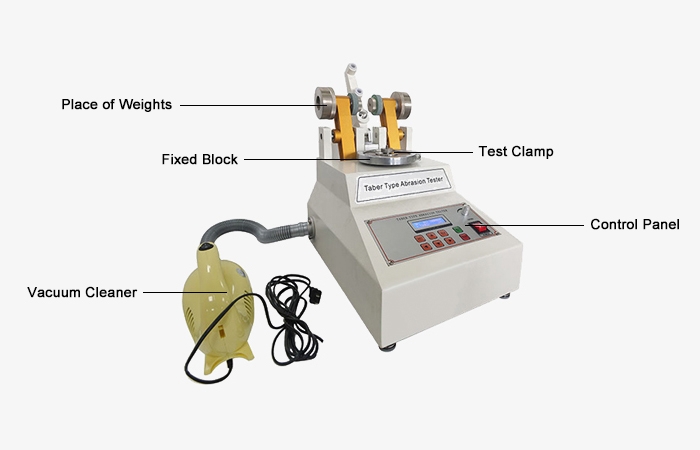

- The taber abrasion tester features a unique wear process, placing the test material on a rotating platform while two abrasive wheels apply a specified weight to create abrasion.

- SISCO taber abrasion tester is made with a stainless steel base, providing corrosion and rust resistance.

User-Friendly Design with Broad Material Compatibility

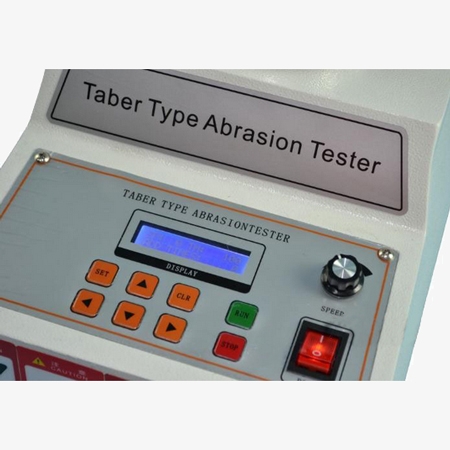

- This abrasion tester features a well-designed control panel with a one-touch emergency stop for safer and more convenient operation.

- The tester is suitable for abrasion testing of materials such as fabric, plywood, floor tiles, glass, and natural rubber. It complies with standards including DIN 53754 and ASTM D3884.

Applications

Taber abrasion tester is widely used to assess the wear resistance of a variety of materials, including textiles, coatings, wood, laminates, rubber, flooring, and ceramics. It's essential in industries such as automotive, construction, electronics, and packaging, where product durability and surface quality are critical. The tester helps manufacturers ensure product quality, meet industry standards, and reduce failure risks in high-wear environments.

Cloth

Paper

Floor

Feather

| Model | SISCO-TAT-SF |

| Wear Wheel | Ф2"(Max. 45mm)×(W)1/2" |

| Wear Wheel Center Distance | 63.5mm |

| Wear Wheel and Specimen Center Distance | 37~38mm |

| Rotation Speed | 60 ~72 r.p.m (adjustable) |

| Load Weight | 250g, 500g, 750g |

| Counter | LED display 0~99999999 times |

| Test Piece | Inner diameter (D) 8mm, outer diameter 110mm |

| Distance Between Sample And Suction Port | 3mm |

| Volume (approx.) | 45×35×42cm |

| Weight (approx.) | 30Kg |

| Power Supply | AC220V, 50Hz, 10A |

Details

Q1: What is an abrasion tester used for?

A1: An abrasion tester is used to evaluate how resistant a material is to wear caused by friction or rubbing. It simulates real-world conditions where surfaces experience repeated contact, helping manufacturers understand how long a product will last. It’s commonly used for testing coatings, plastics, textiles, rubber, leather, flooring, and other materials where surface durability matters.

Q2: What materials can be tested with an abrasion tester?

A2: An abrasion tester can be used to test a variety of materials such as plastics, paints, coatings, textiles, rubber, leather, wood, flooring, paper, and even glass or ceramics, depending on the setup. It's suitable for almost any material where assessing surface wear and durability is important.

Q3: What factors affect abrasion test results?

A3: Abrasion test results can be affected by several factors, including the type and hardness of the abrasive material used, the applied load or pressure during the test, the speed and duration of the test, the surface texture of the sample, environmental conditions like temperature and humidity, and whether the test is done dry or with lubrication. Consistency in these variables is key to getting reliable and comparable results.

Tips: How to maintain an abrasion tester and ensure accurate?

- Clean the machine after each use to remove dust, debris, and test residue.

- Inspect abrasive wheels or pads regularly and replace them when worn or damaged.

- Calibrate the tester periodically according to the manufacturer's specifications to maintain accuracy.

- Lubricate moving parts if recommended, to prevent wear and ensure smooth operation.

- Keep the tester in a stable, dry environment to avoid rust, corrosion, or external damage.

- Follow the user manual for specific maintenance procedures and intervals.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.