The Martindale abrasion tester works by rubbing circular fabric specimens against a standard material under defined pressure, following a Lissajous motion pattern. After completing a set number of cycles, the specimen's pilling level is assessed. The tester is also suitable for evaluating abrasion resistance based on GB/T 13775, ASTM D4966, and ISO 12947 standards.

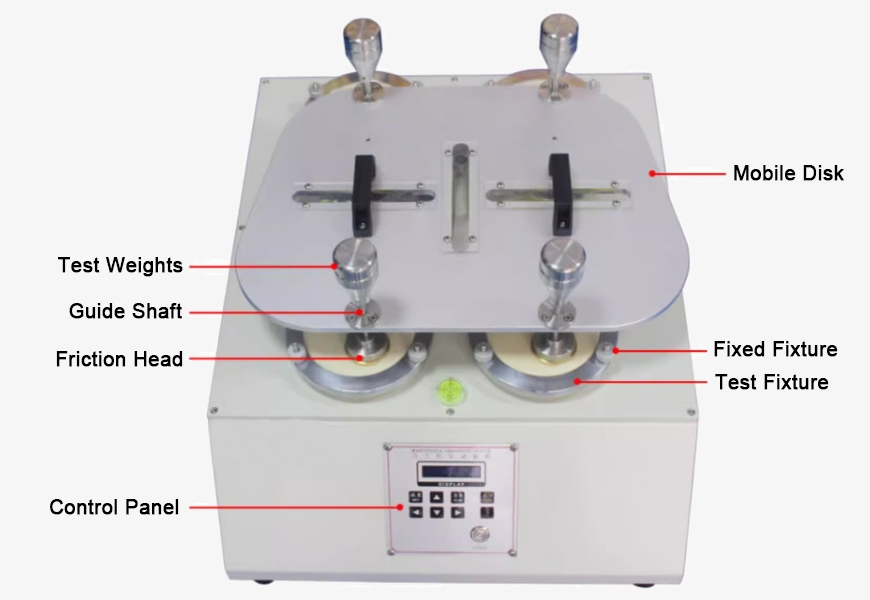

Efficient and Durable Four-station Martindale Tester for Fabric Testing

- The four-station Martindale abrasion tester allows simultaneous testing of four samples, delivering consistent performance, intuitive operation, and precise results for both abrasion and pilling assessments.

- SISCO Martindale tester features a durable stainless steel base that offers strong resistance to corrosion and rust, ensuring long-lasting reliability and consistent performance in lab settings.

User-Friendly and Safe Martindale Tester for Standardized Pilling Tests

- This Martindale tester is designed with an intuitive control panel and includes a one-touch emergency stop for enhanced safety and ease of use.

- The instrument is suitable for evaluating fabric pilling performance in compliance with standards like GB/T 4802.2, ASTM D4970, and ISO 12945-2.

Applications

The Martindale abrasion tester is widely used to evaluate the abrasion resistance and pilling performance of textiles, nonwovens, leather, and automotive interior materials. It simulates real-world wear conditions through a Lissajous motion path under specified pressure, making it ideal for quality control and research in apparel, upholstery, and vehicle interior industries.

Cloth

Furniture Fabrics

Automotive Interior

Feather

| Model | SISCO-MAT-BT4 |

| Cumulative Counting | 0~999999 times |

| Maximum Stroke | 24+0.5mm, 60.5±0.5mm |

| Weight of Pressurized Material | Gripper: 200±1g |

| Weight of Clothing Sample: 395±2g | |

| Weight of Furniture and Decoration Sample: 594±2g | |

| Stainless steel butterfly: 260±1g | |

| Relative Movement Speed Between Gripper and Grinding Table | 50-2r/min |

| Weight of Pressurized Hammer | 2385±10g |

| Consumables | 4 pieces of wool felt, 4 pieces of test cotton cloth |

| Power Supply | Ac220V/50HZ |

| Weight | 65kg |

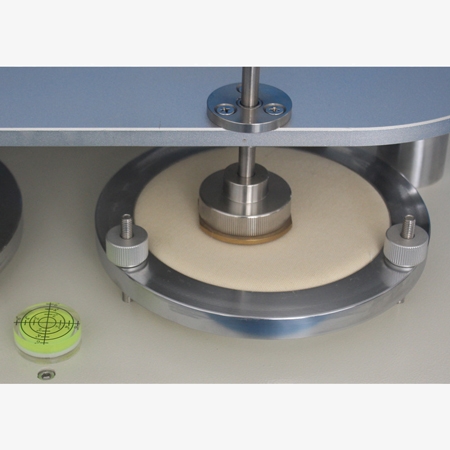

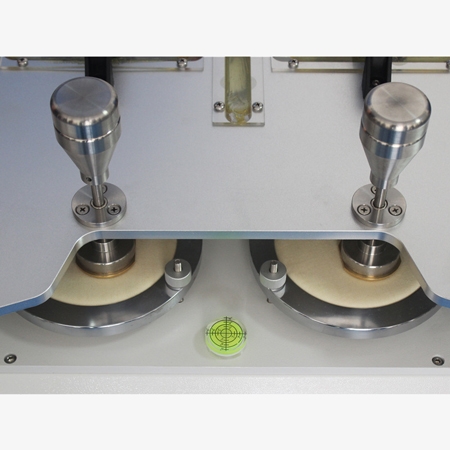

Product Details

Q1: What is the purpose of the Martindale abrasion tester?

A1: The purpose of the Martindale abrasion Tester is to assess the wear resistance and pilling performance of textiles, leather, and similar materials by simulating natural wear through controlled rubbing motion.

Q2: How does a Martindale abrasion tester work?

A2: A Martindale abrasion tester works by rubbing a test specimen against a standard abrasive material in a circular, Lissajous motion under a specified pressure. This simulates natural wear. After a set number of cycles, the specimen is inspected for signs of wear, damage, or pilling.

Q3: What materials can be tested with the Martindale abrasion tester?

A3: The Martindale abrasion tester can be used to test a wide range of materials, including textiles (such as clothing and upholstery fabrics), nonwovens, leather, synthetic leather, coatings, and automotive interior materials.

Tips: What should be paid attention to when using a Martindale abrasion ester?

- The sample must be securely and evenly fixed.

- Use the standard-specified abrasive and pressure.

- Use consumables from the same batch for each test to ensure consistency.

- Control ambient temperature and humidity within the standard-required range.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.