Get a thermocouple thermometer for directly measuring the surface temperature of liquids, vapors and gases from 0°C to 1000°C. It is a K type thermocouple that has 600mm length, M27*2 thread, and waterproof and rust-proof junction box, more stable and durable. SISCO thermocouple is matched with display instruments, recording instruments and electronic regulators, commonly used in the chemical industry, petroleum, machinery, shipbuilding, power generation, etc.

K-type thermocouple is used for temperature measurement of liquid temperature, and gas temperature, and are widely used in the chemical industry, petroleum, machinery, shipbuilding, power generation, textile, printing and dyeing, etc.

- The 600mm thermocouple is the most commonly used temperature detector in medium and low-temperature areas, equipped with a high-temperature resistant thermocouple head, high-frequency anti-interference, and temperature resistance 0-1000°C.

- The thermocouple has a waterproof and rust-proof junction box, stable, strong, durable, and long service life.

- The interior of the thermocouple thermometer uses high-frequency magnetic beads for more precise use.

- Both a two-wire system and a four-wire system can be selected, and the measurement is more stable.

- The German back cover technology is adopted, and the thermocouple thermometer is shock-resistant and pressure-resistant.

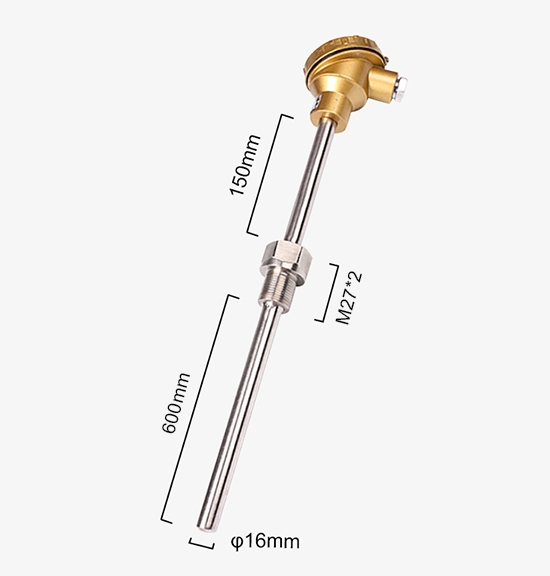

Dimension

Applications

SISCO K type thermocouples are widely used in science and industry, including temperature measurement for kilns, gas turbine exhaust, diesel engines, and other industrial processes. Thermocouples are also used in homes, offices and businesses as temperature sensors in thermostats, and also as flame sensors in safety devices for gas-powered major appliances.

- Model: SISCO-WRN-230-K600

- Range: 0-1000°C

- Thread: M27*2

- Length: 600mm

- Even Wire Diameter: Default 2.5mm

- Installation Method: Fixed Thread device

- Protective Tube Diameter: Default 16mm

- Protective Tube Material: Default 304

Note:

- Thread, insertion depth and cold end length can all be customized. If necessary, please contact us.

- Use 2520 high-temperature resistant material or 310 stainless steel protection tube for long-term temperature measurement above 1000 degrees, and the diameter of the dual wire is 2.5mm or 3mm.

Q1: What is a thermocouple?

A1: A thermocouple is a commonly used temperature-measuring component in a temperature-measuring instrument. It directly measures the temperature and converts the temperature signal into a term electromotive force signal, which is converted into the temperature of the measured medium by an electric meter (secondary meter). The shape of various thermocouples is often very different due to the needs, but their basic structure is almost the same, usually composed of the hot electrode, insulating sleeve protection tube and junction box, etc., usually with a display instrument, recording instrument and electronic adjustment Used in conjunction with the device.

Q2: What is a K-type thermocouple used for?

A2: As a transmitter for measuring temperature, industrial K-type thermocouples are usually used in conjunction with display instruments, recording instruments and electronic regulators. It can directly measure the surface temperature of liquid, vapor and gaseous media and solids ranging from 0°C to 1000°C in various production processes.

Q3: How does a thermocouple work?

A3: A thermocouple is the connection of two different conductors or semiconductors into a closed circuit. When the temperature of the two junctions is different, an electromotive force will be generated in the circuit. This phenomenon is called the hot spot effect, also known as the Seebeck effect. The end directly used to measure the temperature is called the working end, and the other end is called the cold end. The cold end is directly connected to the instrumentation or supporting equipment, and the display instrument will point out the electromotive force generated by the thermocouple.

Tips: Structural Requirements for Thermocouples

The structural form of the thermocouple In order to ensure the reliable and stable operation of the thermocouple, its structural requirements are as follows:

- The welding of the two hot electrodes that make up the thermocouple must be firm.

- The two thermal electrodes should be well insulated from each other to prevent short circuits.

- The connection between the compensation wire and the free end of the thermocouple should be convenient and reliable.

- The protective casing should be able to fully isolate the hot electrode from the harmful medium.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.