sisco megger insulation tester can measure the insulation resistance of large transformers, generators, high-voltage motors and so on. Digital megger can be selected from the test voltages of 500, 1000, 1500V and 2500V, with the capabilities of testing insulation resistance up to 100 GΩ, high performance and reliable.

Megger resistance tester with special adapter jack

The insulation resistance tester is equipped with a special adapter jack, the instrument must be switched off when the adapter is inserted or unplugged.

- Active door

- Adapter jack button

- USB insertion hole

Insulation resistance tester with LCD backlight display

The measurement data is displayed with functional symbols, the readings are clear at a glance and high-definition, and the data can be displayed in a backlight.

Applications

The insulation resistance tester is suitable for measuring the insulation resistance of various electrical equipment and insulating materials such as transformers, motors, cables, switches, electrical appliances, and for maintenance, testing and verification of various electrical equipment.

| Model | SISCO-IRT-UT512 | ||||

| Insulation Resistance (Ω) | Test voltage/accuracy | 500V/1000V/1500V/2500V | 0% ~ 20% | ||

| Measurement range/accuracy | 500V | 1 MΩ ~ 5 GΩ | ±(3%+5) | ||

| 1000V | 2 MΩ ~ 10 GΩ | ±(3%+5) | |||

| 1500V | 5 MΩ ~ 20 GΩ | ±(3%+5) | |||

| 2500V | 10 MΩ ~ 100 GΩ | ±(3%+5) | |||

| Short-circuit current | <1.8mA | ||||

| DC Voltage (V) | Test range/accuracy | 600V | ±(2%+5) | ||

| AC Voltage (V) | Test range/accuracy | 600V | ±(2%+5) | ||

| Features | Display | 9999 counts | |||

| Auto ranging | Yes | ||||

| Auto power off | Yes | ||||

| Low battery indication | Yes | ||||

| Data storage | 18 | ||||

| Comparison measurement | Yes | ||||

| PI | Yes | ||||

| DAR | Yes | ||||

| USB port | Yes | ||||

| LCD backlight | Yes | ||||

| Analog bar graph | 30 | ||||

| Over-range warning | Yes | ||||

| High voltage indication | Yes | ||||

| Timing measurement (Around 15 min) | Yes | ||||

| General | Power supply | 1.5V battery (LR14) x 8 | |||

| Display size | 123mm x 58mm | ||||

| Operating temperature | 0℃ ~ 40℃ (32℉ ~ 104℉) | ||||

| Storage Temperature | -20℃ ~ 60℃ (-4℉ ~ 140℉) | ||||

| Relative Humidity | ≤85%RH @ 0℃ ~ 40℃ below; ≤90%RH @ -20℃ ~ 60℃ |

||||

| Product weight | 2kg | ||||

| Product size | 202mm x 155mm x 94mm | ||||

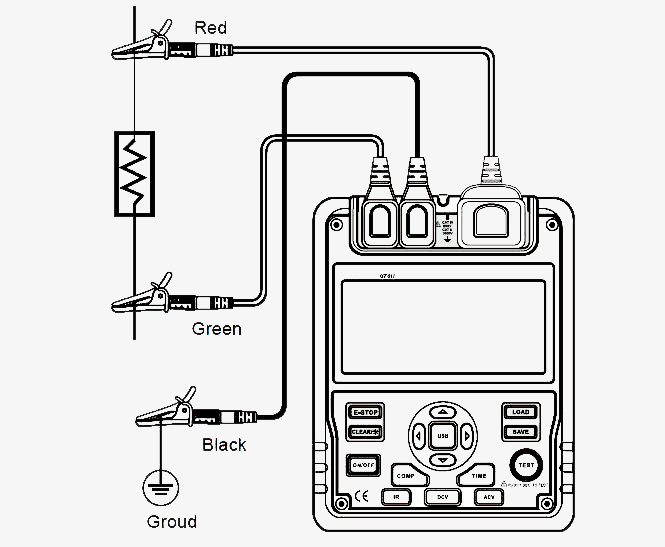

| Standard accessories * | 2*single plug test lead with alligator clip (black and green), 1*double plug test lead with alligator clip (red), batteries, USB cabel, PC software CD | ||||

Note: * Batteries are Not Included for air shippment.

Insulation Resistance Tester Wiring Diagram

Q1: What is a insulation tester?

A1: Insulation tester, also known as megohmmeter or meggers, are widely used to measure cables for generators, motors, power transformers, wiring, appliances and other electrical installations such as control, signal, communication and power ) insulation resistance. They are often used in routine maintenance procedures to indicate changes in the insulation resistance of a motor over months or years. Large changes in insulation resistance may indicate potential failures. Therefore, regular calibration of the megohmmeter is required to ensure that the meter itself has not changed over time.

Q2: What is insulation resistance?

A2: Insulation resistance is the DC resistance of the insulation under the specified conditions, that is, the DC voltage is applied to the dielectric, after a certain period of polarization, the resistance corresponding to the leakage current flowing through the dielectric is called insulation resistance. It is the most basic insulation index of electrical equipment and electrical circuit.

Q3: How to measure insulation resistance?

A3: 1. Connect all the lines according to the method measured by the insulation resistance tester. The connection between the measuring lead and the pipe is more suitable for the use of magnetic joints or clips, and the connection point must be free of rust.

2. The measuring instrument should be a 500V/500MΩ (the error here cannot be greater than 10%) insulation tester. Turn the handle of the megohmmeter to reach the specified speed for 10 seconds. The resistance value indicated by the megohmmeter stably is the insulation resistance value of the insulating joint (flange), which is required to be greater than 10 megohms.

Tips: How to use megger insulation tester?

- Be familiar with the instruction manual of the megger insulation tester, and have a comprehensive understanding of the structure, performance and usage of the digital insulation tester.

- Prepare the necessary tools and all the accessories of the digital insulation tester for the measurement, and wipe the digital insulation tester and the grounding probe clean, especially the grounding probe, be sure to clean the surface of the dirt and rust that affect the conductivity.

- Disconnect the connection point between the grounding trunk line and the grounding body or the connection points of all grounding branch lines on the grounding trunk line, so that the grounding body is separated from any connection and becomes an independent body.

- Insert the two grounding probes into the ground 20m and 40m away from the grounding body along the radiation direction of the grounding body, and the insertion depth is 400mm.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.