sisco insulation resistance tester is a megohmmeter that offers insulation resistance test up to 5.0G ohm and test voltage of 100, 250, 500 and 1000 volts. Megger resistance tester is used for insulation resistance measurement in various kinds of electrical equipment such as transformer, electric motors, cables, switches, electrical appliance and so on.

External structure

- EARTH: Insulation resistance test sampling jack

- G: Voltage measurement input negative jack

- V: Voltage measurement input positive jack

- LINE: High voltage output jack for insulation resistance tester

- Display LCD screen

- Backlit button

- Data hold button

- Insulation resistance measurement button

- Function button

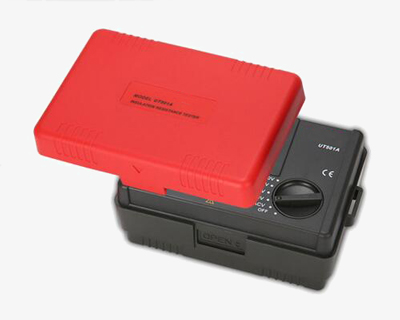

Megger resistance tester with sturdy protective cover

When not measuring, the cover can be closed to protect the keys and screen of the insulation resistance tester.

Insulation resistance tester with LCD backlight display

The measurement data is displayed with functional symbols, the readings are clear at a glance and high-definition, and the data can be displayed in a backlight.

Applications

The insulation resistance tester is suitable for measuring the insulation resistance of various electrical equipment and insulating materials such as transformers, motors, cables, switches, electrical appliances, and for maintenance, testing and verification of various electrical equipment.

| Model | SISCO-IRT-UT501A | ||||

| Insulation Resistance (Ω) | Test voltage/accuracy | 100V/250V/500V/1000V | 0% ~ 10% | ||

| Measurement range/accuracy | 100V | 0.00 MΩ ~ 100 MΩ | ±(3%+5) | ||

| 250V | 0.00 MΩ ~ 99.9 MΩ | ±(3%+5) | |||

| 100 MΩ ~ 5.0 GΩ | ±(5%+5) | ||||

| 500V | 0.00 MΩ ~ 99.9 MΩ | ±(3%+5) | |||

| 100 MΩ ~ 5.0 GΩ | ±(5%+5) | ||||

| 1000V | 0.00 MΩ ~ 99.9 MΩ | ±(3%+5) | |||

| 100 MΩ ~ 5.0 GΩ | ±(5%+5) | ||||

| Load current | 100V (R=100kΩ) 1mA | 0% ~ 10% | |||

| 250V (R=250kΩ) 1mA | 0% ~ 10% | ||||

| 500V (R=500kΩ) 1mA | 0% ~ 10% | ||||

| 1000V (R=1MΩ) 1mA | 0% ~ 10% | ||||

| Short-circuit current | <2mA | ||||

| AC Voltage (V) | Test range/accuracy | 30V ~ 750V (50Hz/60Hz) | ±(2%+3) | ||

| Features | Display | 1999 count | |||

| Auto ranging | Yes | ||||

| Low battery indication | Yes | ||||

| LCD backlight | Yes | ||||

| Light alarm | Yes | ||||

| Buzzer alarm | Yes | ||||

| High voltage indication | Yes | ||||

| Over load indication | Yes | ||||

| Auto discharge | Yes | ||||

| Test voltage secondary display | Yes | ||||

| 10 MΩ internal resistance test | Yes | ||||

| General | Power supply | 1.5V battery (LR6) x 6 | |||

| Display size | 70.6mm x 34mm | ||||

| Working condition | 0℃ ~ 35℃, ≤75%RH | ||||

| Altitude | ≤2000m | ||||

| Storage condition | -20℃ ~ 60℃, ≤80%RH | ||||

| Product weight | 500g | ||||

| Product size | 150mm x 100mm x 71mm | ||||

| Standard accessories * | Batteries, test leads, alligator clips, gallus | ||||

Note: * Batteries are Not Included for air shippment.

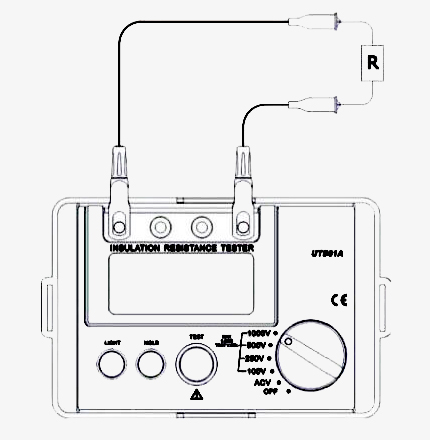

Insulation Resistance Tester Wiring Diagram

Q1: What is a insulation tester?

A1: Insulation tester, also known as megohmmeter or meggers, are widely used to measure cables for generators, motors, power transformers, wiring, appliances and other electrical installations such as control, signal, communication and power ) insulation resistance. They are often used in routine maintenance procedures to indicate changes in the insulation resistance of a motor over months or years. Large changes in insulation resistance may indicate potential failures. Therefore, regular calibration of the megohmmeter is required to ensure that the meter itself has not changed over time.

Q2: What is insulation resistance?

A2: Insulation resistance is the DC resistance of the insulation under the specified conditions, that is, the DC voltage is applied to the dielectric, after a certain period of polarization, the resistance corresponding to the leakage current flowing through the dielectric is called insulation resistance. It is the most basic insulation index of electrical equipment and electrical circuit.

Q3: How to measure insulation resistance?

A3: 1. Connect all the lines according to the method measured by the insulation resistance tester. The connection between the measuring lead and the pipe is more suitable for the use of magnetic joints or clips, and the connection point must be free of rust.

2. The measuring instrument should be a 500V/500MΩ (the error here cannot be greater than 10%) insulation tester. Turn the handle of the megohmmeter to reach the specified speed for 10 seconds. The resistance value indicated by the megohmmeter stably is the insulation resistance value of the insulating joint (flange), which is required to be greater than 10 megohms.

What are the functions of insulation resistance testers?

- Repair faulty parts

Technicians use tests to verify high insulation resistance between conductors and ground or adjacent conductors. By testing the insulation resistance of different components in the system (transformers, switchgear, conductors, motors), technicians can isolate and repair failed components. - Improve system performance

Before energizing the system, verifying that it is sound using insulation testing can improve the performance of the system. - Found manufacturing process problems and equipment defects

Insulation testing can uncover manufacturing process problems and equipment defects that would not normally be discovered until the equipment fails. In the EU, the test is mandatory, even for the smallest civilian systems.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.