Hot selling portable gas analyzer can detect NO2 (0-10 ppm), SO2 (0-10 ppm), CO (0-20 ppm), and O3 (0-10 ppm) 4 gases accurately. sisco gas analyzer features a high-definition LCD display for measurement data, large capacity rechargeable lithium battery, long working time, compact and lightweight design, easy to carry and operate. 1-18 gases can be customized.

Portable multi gas analyzer is designed for 4 gas (NO2, SO2, CO, O3).

- sisco gas analyzer uses world top brand sensors to guarantee the test results accurately.

- Multiple industrial pump gas sampling, ten grades of pumping flow rate for selection.

- Multi-display mode is switchable.

- Various gas concentration units can be shifted freely.

- Modular internal structure (can be customized for 1-18 gas detection).

- Portable multi gas analyzer is available with an independent SD memory card that can view and delete the historical detection data.

- High-capacity rechargeable lithium polymer battery, long operation time and standby time.

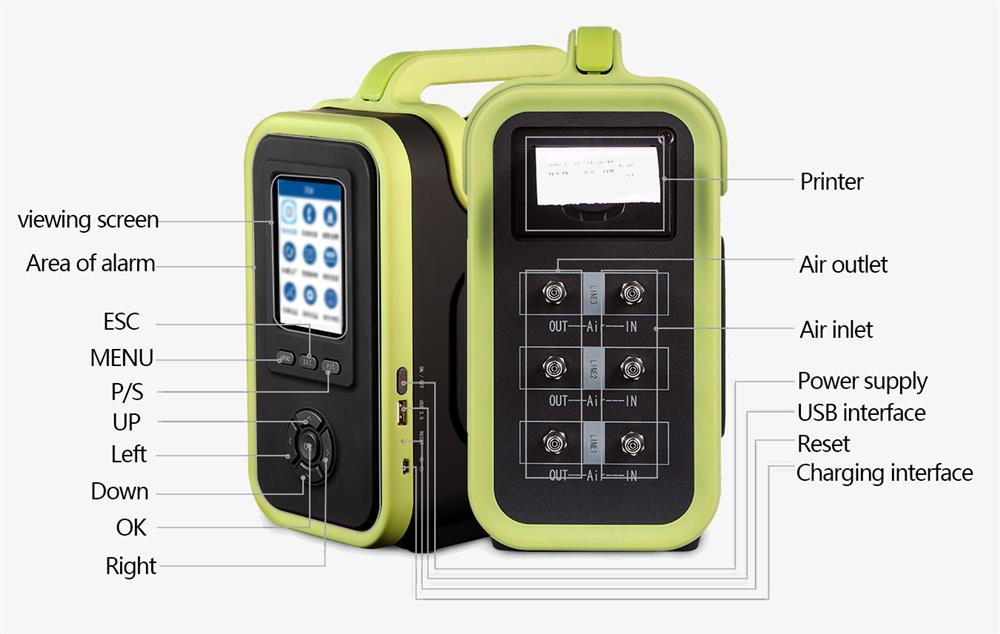

3.5-inch HD LCD screen and 120-degree wide view, beautiful and useful menu interface.

Details

Applications

sisco portable gas analyzers can be widely used in university laboratories, research institutes, large oil refineries, metallurgical plants, inspection and quarantine bureaus, hospitals, mines, tunnel engineering sites, etc.

| Model | GD600-4GAS |

| Sampling Method | Pumping suction, 10 grades adjustable, flow rate range 0-500 mL/min. |

| Detection Principle | Electrochemistry |

| Detecting Gas * | NO2, SO2, CO, O3 |

| Measure Range | NO2: 0 to 10 ppm, SO2: 0 to 10 ppm, CO: 0 to 20 ppm, O3: 0 to 10 ppm |

| Resolution | NO2: 0.001ppm, SO2: 0.001ppm, CO: 0.001ppm, O3: 0.001ppm |

| Accuracy | ≤±2% F.S. |

| Data Storage | 8G SD memory card |

| Alarm | Buzzer, red LED and alarm status on the display, fault alarm, pump abnormal alarm, low battery alarm |

| Display | 3.5 inch HD LCD display with resolution 320*480 |

| Language | Chinese/English |

| Battery | Large-capacity rechargeable lithium battery |

| Explosion-proof Grade | Ex ia llC T4 |

| Protection Grade | IP65 |

| Certification | CE, ATEX |

| Operating Temperature | -40℃~70℃ |

| Operating Humidity | 0~95%RH (non-condensing) |

| Dimension | 260*230*120mm |

| Weight | 3700g |

| Standard Accessories | User manual, Micro-USB cable, Water vapor smoke filter, Intake sampling rod, 600mm tube, Carrying case |

| Optional Accessories * | Printer (built-in printer or external Bluetooth printer), Pressure sensor, High-temperature gun |

* Note:

- The detected gas can be customized. This multi-gas analyzer can detect up to 18 gases simultaneously, such as combustible gas, O2, CO2, H2S, NH3, NO, VOC, and so on.

- If you have any requirements about the detected gases and measuring range, please feel free to contact us. * For the optional accessories, please contact us if you need them.

Gas Detector Catalog & User Manual

SISCO Gas Detector Catalogue

SISCO Gas Detector Catalogue SISCO GD200 Portable Gas Detector User Manual

SISCO GD200 Portable Gas Detector User Manual SISCO GD300 Online Fixed Gas Detector User Manual

SISCO GD300 Online Fixed Gas Detector User Manual SISCO GD400 Explosion Proof Portable Gas Detector User Manual

SISCO GD400 Explosion Proof Portable Gas Detector User Manual SISCO GD500 Handheld Multi Gas Detector User Manual

SISCO GD500 Handheld Multi Gas Detector User Manual SISCO GD600 Multi Gas Analyzers User Manual

SISCO GD600 Multi Gas Analyzers User Manual SISCO Gas Detector Communication Protocol V1.0

SISCO Gas Detector Communication Protocol V1.0 SISCO Single Stage Pressure Regulator User Manual

SISCO Single Stage Pressure Regulator User Manual SISCO Gas Detector Data Downloading Operation Instruction

SISCO Gas Detector Data Downloading Operation Instruction

Gas Detector Software

Q1: Difference between Gas Detector and Gas Analyzer

- Construction

Gas detectors are generally composed of gas detectors and signal conversion circuits, while analyzers not only have gas detectors and signal conversion circuits, but also a complete set of gas path analysis systems. - Detection methods

The detection method of gas detectors is often diffusion type, which can only be detected in the air. The gas analyzer takes the collected gas, and then sucks it into the interior for inspection and analysis by rising out of the sampling tube. - Data Accuracy

The gas detector can only provide qualitative analysis results for the gas. The gas analyzer is an unknown gas concentration, and through the analysis instrument, the gas type and concentration contained in the unknown gas are given. - Measurement purpose

The detection purpose of the gas detector is mainly for safety protection and preventive detection. The detection of the gas analyzer is mainly for the gas composition and content in the measured environment. The detection accuracy of the gas analyzer is higher than that of the gas detector. - Measurement method

When the gas detector is used, it is only necessary to place the gas detector in the measured environment and the instrument can display the value and complete the detection. The gas analyzer must introduce gas into the instrument and strictly adjust the technical conditions, such as temperature, pressure, flow rate, etc. Only when the operator adjusts the instrument correctly, can accurate measurement data be obtained.

Tips: Natural diffusion vs. pump suction gas detectors

Gas detectors all know that there are two common detection methods, one is natural diffusion, and the other is pump suction. But what is the difference between the two? The natural diffusion type is to slowly sense the gas without applying any external force. The pump suction type uses a self-priming pump to inhale by itself. For example, the human nose responds faster, so it is necessary to choose the right detection method to effectively detect the gas.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.