Note*: This flow meter is not equipped with explosion-proof certification. Caution is required when using it with flammable media.

The oval gear flow meter is a kind of positive displacement flow meter. As the fluid being measures passes thru the meter, it rotates 2 oval gears in measuring cavity to displace a precise volume of fluid.

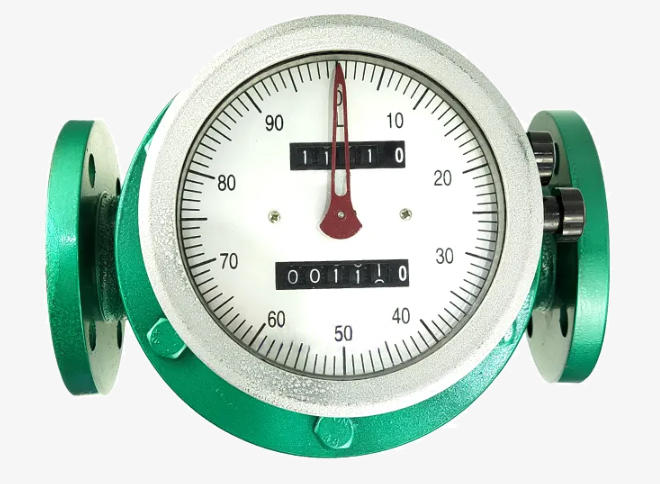

Display with zero return

- The pointer indicates the flow rate.

- The double value shows the single and cumulative flow rate respectively.

Oval flow meter with exquisite workmanship

- Multi-process construction, strong pressure resistance.

- Spray paint of cast iron makes the service life of flowmeter longer.

Application

Oval gear flow meter consists of two oval gears that rotate inside a housing. The flow of liquid causes the gears to rotate, and the rotation is proportional to the flow rate. Oval flow meter is widely used in chemical industry, medical industry and metallurgical industry.

| Model | SISCO-LC-E |

| Display | pointer single time, cumulative intelligent liquid crystal display |

| Output Signal | output of pulse, 4-20 mA output, RS485 |

| Return to Zero | optional |

| Measurement Medium | diesel oil, gasoline |

| Port Size | DN10-200 |

| Measurement Range | 0.04-340 m3/h |

| Accuracy | 0.5 grade, 0.2 grade |

| Medium Temperature | 20 ℃ ~ 100 ℃ |

| Working Pressure | 106 Mpa, 25 Mpa, 6.4 Mpa |

| Working Temperature | 30 ℃ ~ 80 ℃ |

| Power Supply | DC 12V ~ DC 24V |

| Protection Level | IP65 |

| Explosion Proof Grade | CT6 |

| Material | cast iron, cast steel, stainless steel |

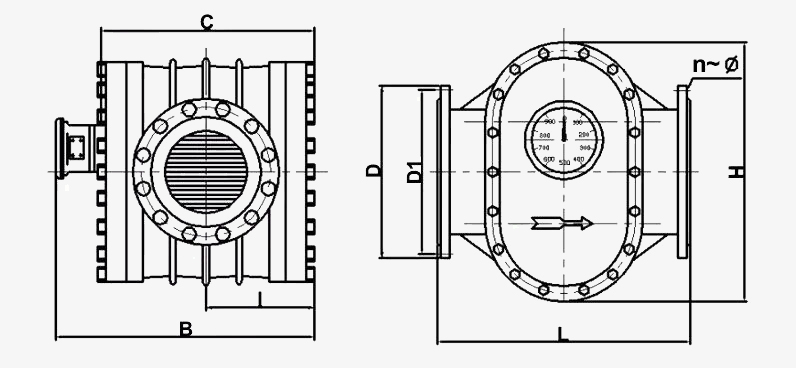

Dimension (Unit: mm)

| DN | L | H | B | C | I | D | D1 | N | φ |

| 10 | 150 | 100 | 210 | 120 | 45 | 90 | 60 | 4 | 14 |

| 15 | 170 | 118 | 226 | 136 | 48 | 95 | 65 | 4 | 14 |

| 20 | 200 | 150 | 238 | 148 | 53 | 105 | 75 | 4 | 14 |

| 25 | 260 | 180 | 246 | 156 | 60 | 115 | 85 | 4 | 14 |

| 40 | 245 | 180 | 271 | 181 | 77 | 145 | 10 | 4 | 18 |

| 100 | 515 | 418 | 458 | 278 | 131 | 215 | 180 | 8 | 18 |

| 150 | 540 | 515 | 557 | 377 | 210 | 280 | 240 | 8 | 23 |

| 200 | 650 | 650 | 624 | 444 | 247 | 335 | 295 | 12 | 23 |

Q1: Can a oval flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a oval flow meter need to be calibrated?

A2: During the production of a flow meter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: Do oval flow meters have temperature compensation?

A3: Yes. As long as these temperature variations are within the temperature compensation range, the output reading compensates for the temperature variations.

Tips: How does oval flow meter work?

Oval gear flow meters are a type of positive displacement flow meter that operates based on the principle of the flow-induced rotation of oval gears. The basic components of an oval gear flow meter include two oval-shaped gears that are placed in a chamber. The chamber has an inlet and an outlet for the fluid flow, and the gears are connected to a shaft that rotates as the fluid passes through the meter.

As the fluid flows through the meter, it enters the chamber and pushes the gears in a rotation. The rotation of the gears is proportional to the volume of fluid that has passed through the meter. The rotation of the gears is detected by sensors that are placed outside the chamber, and the output signal is sent to a display or a data acquisition system.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.