Wall mounted ultrasonic flow meter applies to measure all kinds of pure liquid, 10-36V wide voltage power supply, RS485 communication, with good stability, small zero point drift, high measurement accuracy, wide range ratio and strong anti-interference characteristics.

Real-time measurement

- Real-time display of instantaneous and accumulated values

- Compatible with 4-20mA/OTC pulse, RS485 communication, and other functions.

- IP65 protection rating for long-term use in harsh field environments.

Ultra-large scale IC design

- Exclusive SMT automatic placement circuit.

- Guaranteed high-quality product performance.

- Extremely low repair rate and maintenance effort.

Application

Wall-mounted ultrasonic flow meter has ultra-large scale integrated circuit design, low hardware number, low voltage operation, multi-pulse emission, low power consumption, high reliability, anti-interference, and good applicability. Optimized intelligent signal adaptive processing, the user does not need any circuit adjustment, as convenient and simple as using a multimeter. Widely used in environmental protection, petrochemical, metallurgy, paper making, food, pharmaceutical, and other industries.

| Model | SISCO-MIK-1158 |

| Flow Rate Range | 0.01~5.0m/s (0.03~16ft/s) |

| Accuracy Class | Grade 1 |

| Pipe Diameter Range | 25mm~600mm (1° ~24* ) |

| Measuring Medium | Water, oil and other single medium liquid |

| Pipe Material | Carbon steel, stainless steel, PVC |

| Output | OCT pulse output: 0-5000Hz |

| Analog Output | 4~20mA, maximum load resistance 7500 |

| Communication Interface | RS485 communication interface supports MODBUS protocol |

| Power Supply | 10~36VDC/1A |

| Transmitter Installation Environment Temperature | -10℃ ~ 50℃ |

| Special Sensor Measurement Medium Temperature | 0℃~ 80℃ |

| Transmitter Material | PC / ABS plastic housing |

| Protection Class | IP65 |

| Sensor Material | Sealed design, protection class IP68 |

| Standard Cable Length | 9m (30ft) |

| Transmitter Weight | 0.7kg |

| Sensor Weight | 0.4kg |

Transducer Selection

| Transducer | Measuring Pipe Size Range | Temperature Range | Dimensions (mm) |

| Standard clamp-on transducer - Small | DN32-DN100 | -40℃~90℃ | 45*25*32 |

| Standard clamp-on transducer - Medium | DN50-DN700 | 64*39*44 | |

| Standard clamp-on transducer - Large | DN300-DN6000 | 97*54*33 | |

| High-temp clamp-on transducer - Small | DN32-DN100 | -30℃~160℃ | 45*25*32 |

| High-temp clamp-on transducer - Medium | DN50-DN700 | 64*39*44 | |

| High-temp clamp-on transducer - Large | DN300-DN6000 | 97*54*33 |

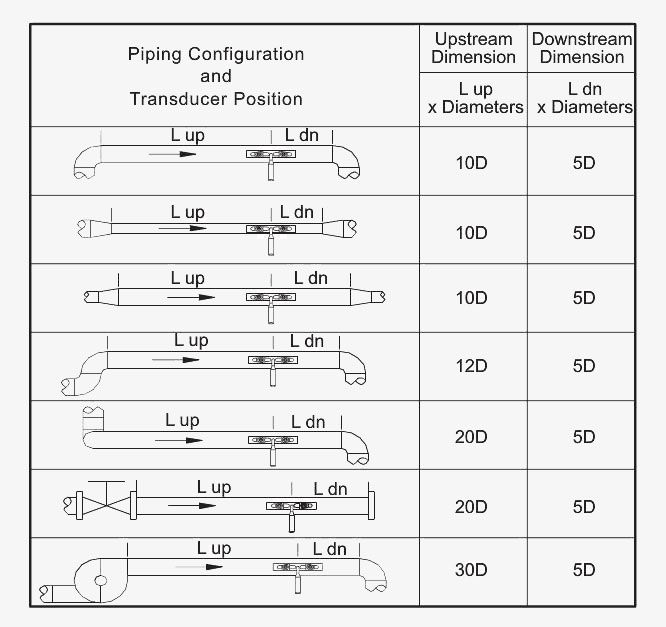

Transducer Installation

1. point selection

Ultrasonic sensor installation should avoid the location of the clock 6 points, 12 points, so as to avoid the bottom of the pipe sediment or the upper part of the pipe bubbles, air pockets cavity caused by the signal attenuation. Give full consideration to the structural condition of the inner wall of the pipe, try to choose the pipe section without scaling for measurement, can fully meet the need to put If it can be fully satisfied, the scale should be considered as lining in order to get better measurement accuracy.

2. Measurement position selection

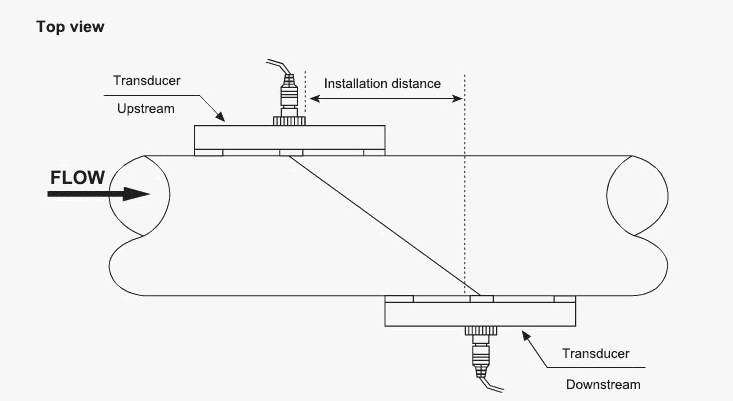

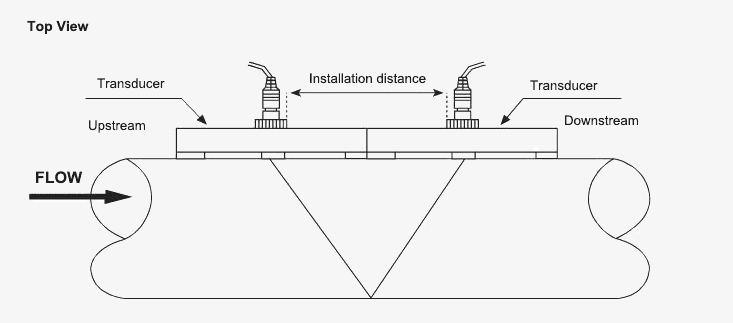

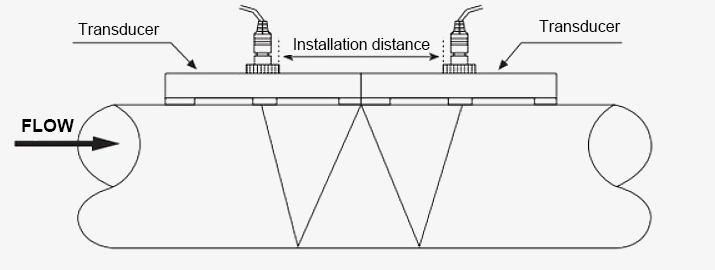

3. Transducer installation method

- Z-installation method: generally suitable for the pipes above DN100mm

- V-installation method: generally suitable for the DN20-300mm pipes

- W-installation method is usually used for pipes of DN10- 100mm.

Packing list

- Flow meter host: can display instantaneous flow, flow rate, and cumulative value; support 4-20mA, pulse output, RS485 communication, etc.

- Sensor probe: Including upstream and downstream sensors, standard cable length of 9 meters, can do IP68 submersible type probe.

- Pipe clamps: sensor fixed on the pipe using accessories, standard.

- Coupling agent: Squeeze the air bubble between the sensor and the contact pipe to improve signal strength and accuracy.

Q1: Can an ultrasonic flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does an ultrasonic flow meter need to be calibrated?

A2: During the production of a flowmeter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: Do ultrasonic flow meters have temperature compensation?

A3: Yes. As long as these temperature variations are within the temperature compensation range, the output reading compensates for the temperature variations.

Do I need to filter the gas entering the meter?

Yes. These meters use a tiny sensor element that is exposed to the gas stream. If this sensor is contaminated, the accuracy may be permanently altered and the sensor may be damaged. It is recommended that a HEPA-rated filter be used upstream of the flow meter. Important: If If you always use clean gas, your flow meter will remain stable and accurate.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.