Electromagnetic flowmeter with stable and reliable, responsive, anti-interference ability, the output signal 4-20mA, nominal diameter DN15 ~ DN200 for selection, electromagnetic flowmeter adaptable, compatible with a variety of pipelines, suitable for all conductive liquids, such as domestic water, industrial water, sewage.

Newly upgraded protective header

- Fully protected meter head, reducing interference and more accurate signal transmission.

- sisco magnetic flowmeter instantaneous flow cumulative flow display.

Magnetic flowmeter adopts pure copper coil

- Pure copper coil ensures stable and accurate signal output.

- Improve instrument reliability.

Application

The magnetic flowmeter is used in petrochemical, iron and steel metallurgy, water supply and drainage, water conservancy irrigation, water treatment, sewage treatment station (environmental sewage control, chemical sewage, electroplating sewage), paper (pulp), mud, medicine, food and other industrial and agricultural flow measurement and control.

| Model | SISCO-LDG | |

| Medium | Conductivity fluid (≥5uS/cm) | |

| Nominal Diameter * | DN15~DN200 | |

| Nominal Pressure | 1.6MPa | |

| Velocity Range | 0~10m/s | |

| Accuracy | ±0.5%R | |

| Configuration | Integral type or remote type | |

| Highest Medium Temperature | Integral type | +80°C |

| Remote type | +80℃ (CR) or +120℃ (F4) | |

| Turn-down Ratio | Integral type | 20:1 |

| Remote type | 10:1 | |

| Ambient Temperature | Sensor | -25℃~+180℃ |

| Convertor | -10℃~+60℃ | |

| Liner Materials * | Chloroprene rubber (CR) or Polytetrafluoroethylene (F4) (Customized materials: Polyurethane rubber PU, F46) |

|

| Electrode Material * | Stainless steel 316L (Customized electrode: Hastelloy C, Hastelloy B, Titanium, Tantalum, Platinum) |

|

| Form of Electrode | Interpolating | |

| Number of Electrodes | Standard configuration 3-4 electrodes (two measuring electrodes plus a grounding electrode) | |

| Output Signal | 4-20mA | |

| Cable Entry Size | M20 × 1.5 (Nylon waterproof connector) | |

| Supply Voltage* | 110V/220V AC, 50Hz/60Hz; 24V DC ±10% | |

| Power Dissipation | ≤15VA | |

| Communication | RS-485, support standard Modbus-RTU protocol | |

| Flange Standard | Conform to the international GB9119 | |

| Flange Material | Carbon steel | |

| Grounding Ring Material | Stainless steel | |

| Housing Material | Carbon steel | |

| Protection Level | IP65 | |

| Cable Length (Remote Type) | 10m connecting line (Standard) | |

Note:

*Please note that all the options may not be listed in the selecting area, including the nominal diameter, liner materials, electrode materials and so on. If your have any requirements, please contact us.

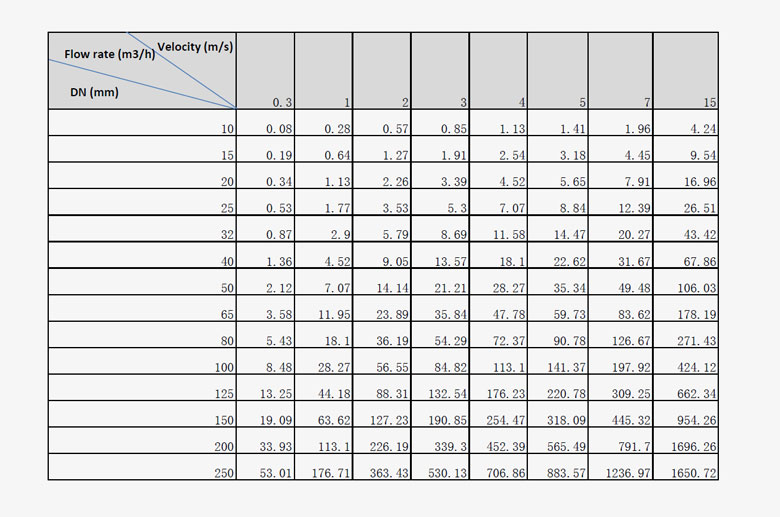

Mag Flowmeter Flow Rate

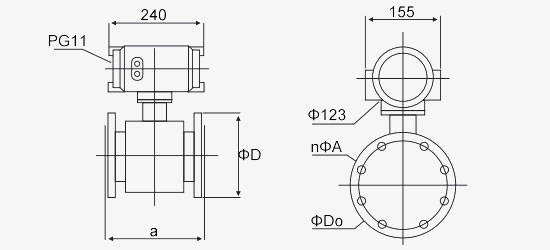

Dimension

| DN | a | ∅D | ∅Do | n∅A |

| 15 | 200 | 95 | 65 | 4*14 |

| 20 | 200 | 105 | 75 | 4*14 |

| 25 | 200 | 115 | 85 | 4*14 |

| 32 | 200 | 140 | 100 | 4*18 |

| 40 | 200 | 150 | 110 | 4*18 |

| 50 | 200 | 165 | 145 | 4*18 |

| 65 | 250 | 185 | 145 | 8*18 |

| 80 | 250 | 200 | 160 | 8*18 |

| 100 | 250 | 220 | 180 | 8*18 |

| 125 | 250 | 250 | 210 | 8*18 |

| 150 | 300 | 285 | 240 | 8*22 |

| 200 | 350 | 340 | 295 | 8*22 |

Q1: Can a magnetic flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a magnetic flow meter need to be calibrated?

A2: During the production of a flowmeter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: How often do magnetic flow meters need to be calibrated?

A3: Magnetic recalibrates the flowmeter every two years (every two years), or at the minimum frequency specified by the manufacturer. The manufacturer's specified minimum frequency meter readings are pressure corrected and, if necessary, corrected for moisture content.

Tips: What is a magnetic flow meter?

A magnetic flowmeter or electromagnetic flowmeter is an instrument based on the principle of electromagnetic induction, which measures the flow rate of a conductive fluid by the electric potential generated by the conductive fluid passing through an external magnetic field. The structure of magnetic flowmeter mainly consists of a magnetic circuit system, measuring tube, electrode, housing, liner, converter, etc.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.