Low-price turbine flowmeter available for organic liquids, inorganic liquids, food, pharmaceuticals, and other industries, line size optional DN4~DN200mm, 4-20mA signal output and LCD display instantaneous flow / cumulative flow optional, RS485 is also available, turbine flowmeter with high accuracy, good repeatability, simple structure.

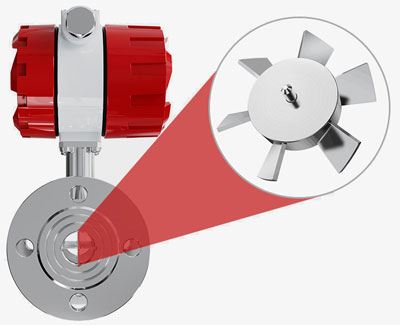

Smart meter head accurate and stable

- Turbine flowmeter with intelligent meter head.

- Cubic meters, tons, and other units can be switched to display the required units.

- Anti-interference meter head.

High-pressure resistance, accurate measurement

- One piece forming turbine (non-welded).

- Intelligent lithium battery-powered display for real-time display of traffic.

Application

The turbine flow meter is a kind of flowmeter applying the Carmen vortex principle, used to measure the flow of liquid, gas, and steam, also can measure the turbid liquid containing tiny particles, and impurities, widely used in petroleum, chemical, pharmaceutical, paper, metallurgy, electric power, environmental protection, food, and other industries.

| Model | SISCO-LWGY |

| Measuring Medium | liquid (water, liquefied petroleum gas, refined oil, light crude oil, organic liquid, inorganic liquid, and other liquid without fiber, particulate impurities) |

| Medium Viscosity | < 5 × 10-6 m2/s (for the liquid with more than 5 × 10-6 m2/s, the flowmeter needs to be calibrated before use.) |

| Nominal Diameter * | DN4 ~ DN200 mm |

| Measurement Accuracy | 1.0%R (For higher accuracy 0.5%R, please contact us.) |

| Pressure Range | 6.3MPa, 2.5MPa, 1.6MPa |

| Medium Temperature | -20 ℃ ~ +120 ℃ (stainless steel measuring tube) |

| Environmental Conditions | Ambient temperature: -20 ℃ ~ +60 ℃ Relative humidity: 5% to 95% Atmospheric pressure: 86kPa ~ 106kPa |

| Power Supply | 24V DC |

| Output Signal * | three-wire pulse output, or two-wire 4-20mA output (Optional) |

| Display * | LCD screen, can display instantaneous flow / accumulative flow (Optional) |

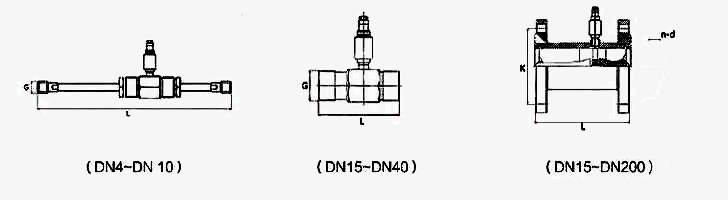

| Connection | Threaded connection (DN4~DN40) Flange connection (DN50 ~ DN200) |

| Communication * | RS485 (Optional) |

| Protection Class | IP65 (IP68 can be customized) |

Flow Range

| Size (mm) | Flow Range (m3/h) | Pressure Range | Connection |

| DN4 | 0.04 ~ 0.4 | 6.3MPa | Threaded |

| DN6 | 0.1 ~ 0.6 | 6.3MPa | Threaded |

| DN10 | 0.2 ~ 1.2 | 6.3MPa | Threaded |

| DN15 | 0.6 ~ 6 | 6.3MPa | Threaded |

| DN20 | 0.8 ~ 8 | 6.3MPa | Threaded |

| DN25 | 1 ~ 10 | 6.3MPa | Threaded |

| DN32 | 1.5 ~ 15 | 6.3MPa | Threaded |

| DN40 | 2 ~ 20 | 6.3MPa | Threaded |

| DN50 | 4 ~ 40 | 2.5MPa | Flange |

| DN65 | 7 ~ 70 | 1.6MPa | Flange |

| DN80 | 10 ~ 100 | 1.6MPa | Flange |

| DN100 | 20 ~ 200 | 1.6MPa | Flange |

| DN125 | 25 ~ 250 | 1.6MPa | Flange |

| DN150 | 30 ~ 300 | 1.6MPa | Flange |

| DN200 | 80 ~ 800 | 1.6MPa | Flange |

Dimension

| Size (mm) | L (mm) | G (inch) | K (mm) | d (mm) | n (number of holes) |

| DN4 | 225 | G1/2" | — | — | — |

| DN6 | 225 | G1/2" | — | — | — |

| DN10 | 345 | G1/2" | — | — | — |

| DN15 | 75 | G1" | Ф65 | Ф14 | 4 |

| DN20 | 80 | G1" | Ф75 | Ф14 | 4 |

| DN25 | 100 | G5/4" | Ф85 | Ф14 | 4 |

| DN32 | 140 | G2" | Ф100 | Ф14 | 4 |

| DN40 | 140 | G2" | Ф110 | Ф18 | 4 |

| DN50 | 150 | G5/2" | Ф125 | Ф18 | 4 |

| DN65 | 170 | — | Ф145 | Ф18 | 4 |

| DN80 | 200 | — | Ф160 | Ф18 | 8 |

| DN100 | 220 | — | Ф180 | Ф18 | 8 |

| DN125 | 250 | — | Ф210 | Ф18 | 8 |

| DN150 | 300 | — | Ф240 | Ф22 | 8 |

| DN200 | 360 | — | Ф295 | Ф22 | 12 |

Q1: Can a turbine flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a turbine flow meter need to be calibrated?

A2: During the production of a flowmeter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: How often do turbine flow meters need to be calibrated?

A3: Magnetic recalibrates the flowmeter every two years (every two years), or at the minimum frequency specified by the manufacturer. The manufacturer's specified minimum frequency meter readings are pressure corrected and, if necessary, corrected for moisture content.

Tips: Are there special connection requirements for flow meter analog transmission?

Yes, the analog signal ground circuit of the flowmeter is connected to the power supply ground inside the flowmeter. Therefore, your device must use a voltmeter or analog input circuit with differential input or floating ground. Failure to use this type of grounding will result in measurement errors.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.