The insertion type magnetic flow meter is an inductive instrument for measuring volume flow of conducting fluid. The volume flow of fluid is obtained by measuring the average velocity of fluid with electromagnetic method.

The speed of measurement has been improved

- Insertion type magnetic flow meter adopts with bidirectional measurement system.

- Three integrators are built in magnetic flow meter.

Adopts with stainless steel material

- The flowmeter is made of 304 stainless steel, which is resistant to corrosion and oxidation.

- It can realize uninterrupted maintenance and disassembly.

Application

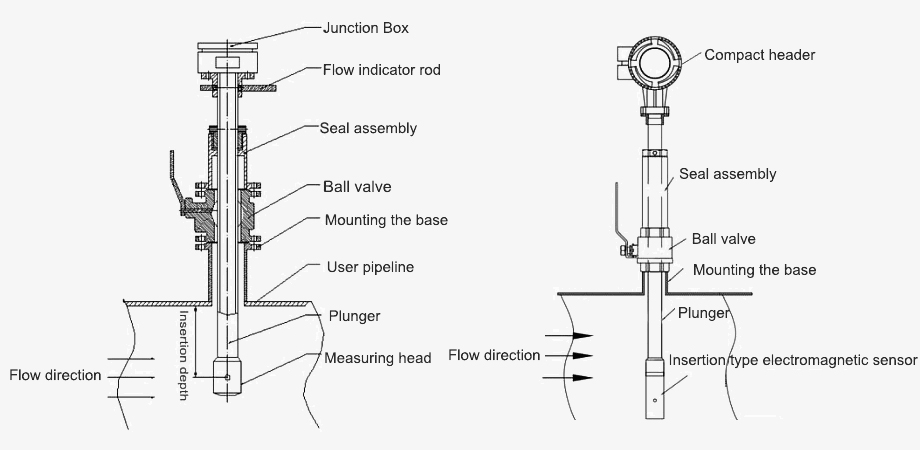

This type of flow meter is called "insertion" because the sensing element is inserted into the fluid stream through a hole in the pipe or duct. The flow meter consists of a sensor probe, which is inserted into the pipe or duct and two electrodes that are placed on opposite sides of the probe. Insertion type electromagnetic flowmeter often used in textile, electric power, metallurgy and petrochemical.

| Model | SISCO-LDGC-MIK |

| Port Size | DN100-3000 mm |

| Working Pressure | 1.6 Mpa |

| Working Temperature | ≤70℃ |

| Upper Limit Range | 1-10 m/s |

| Accuracy of Measurement | ±2.5% |

| Conductivity | ≥50% |

| Medium | water |

| Electrode Material | 304, 304L, 316, 316L, Hastelloy alloy, titanium |

| Converter Output | 4-20 mA output |

| Frequency Output | pluse output |

| Communication Output | RS485 |

| Power Supply | 24V DC, 220V AC |

| Maximum Distance | ≤50m |

| Cable | RVVP double core shielded cable or STT3200 four core three shield cable |

| Compact Type | IP65 / IP68 |

| Buried Depth | Not deeper than 5 meters |

| Repetitiveness | 0.0016 |

| Maxium Measurement Error | ±0.1 ℃ |

Structure:

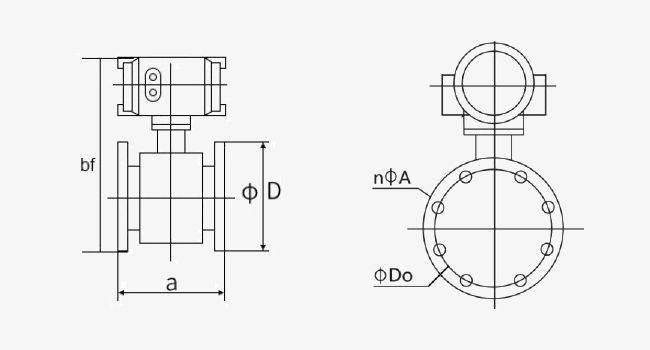

Dimension (Unit: mm)

| DN | a | bf | D | Do | n*A | Pressure Resistance |

| 15 | 200 | 326 | 95 | 65 | 4*14 | 1.6 MPa |

| 20 | 200 | 326 | 105 | 75 | 4*14 | |

| 25 | 200 | 316 | 115 | 85 | 4*14 | |

| 32 | 200 | 331 | 135 | 100 | 4*18 | |

| 40 | 200 | 339 | 145 | 110 | 4*18 | |

| 50 | 200 | 358 | 160 | 125 | 4*18 | |

| 65 | 200 | 370 | 180 | 145 | 4*18 | |

| 80 | 200 | 389 | 195 | 160 | 8*18 | |

| 100 | 250 | 410 | 215 | 180 | 8*18 | |

| 125 | 250 | 440 | 245 | 210 | 8*18 | |

| 150 | 300 | 469 | 280 | 240 | 8*23 | |

| 200 | 350 | 522 | 335 | 295 | 12*23 | |

| 250 | 450 | 824 | 405 | 355 | 12*25 | |

| 300 | 500 | 624 | 440 | 400 | 12*23 | 1 MPa |

| 350 | 550 | 1029 | 500 | 460 | 16*23 | |

| 400 | 600 | 737 | 565 | 515 | 16*25 | |

| 450 | 600 | 786 | 615 | 565 | 20*25 | |

| 500 | 600 | 839 | 670 | 620 | 20*25 | |

| 600 | 600 | 944 | 780 | 725 | 20*30 | |

| 700 | 700 | 1052 | 895 | 840 | 24*30 | |

| 800 | 800 | 1164 | 1015 | 950 | 24*33 | |

| 900 | 900 | 1264 | 1115 | 1050 | 28*33 | |

| 1000 | 1000 | 1374 | 1230 | 1160 | 28*36 | |

| 1200 | 1200 | 1589 | 1405 | 1340 | 32*33 | 0.6 MPa |

Q1: Can a insertion type electromagnetic flow meter have perfect accuracy?

A1: In an ideal world, the flow readings from your process meter would be exactly correct, without any type of deviation. Unfortunately, this is not the case, and the errors inherent in measurement must always be identified, accounted for, and minimized as much as possible.

Q2: Does a insertion type electromagnetic flow meter need to be calibrated?

A2: During the production of a flow meter, several steps are required such as coil winding, lining processing, and electrode assembly. This series of operations can cause a certain amount of error and dispersion in the device, so a calibration process is required to correct the accuracy.

Q3: Do insertion type electromagnetic flow meters have temperature compensation?

A3: Yes. As long as these temperature variations are within the temperature compensation range, the output reading compensates for the temperature variations.

Tips: How to maintain insertion type electromagnetic flow meter?

- Check the wiring connections. Inspect the wiring connections to ensure that they are tight and secure. Loose connections can cause inaccurate readings or intermittent operation.

- Check the electrode alignment. Verify that the electrodes are properly aligned with the flow stream. Misaligned electrodes can cause inaccurate readings or measurement errors.

- Clean the electrodes. Regularly clean the electrodes to remove any buildup or deposits that may accumulate over time. Use a soft-bristled brush or a non-abrasive cleaning solution to avoid damaging the electrodes.

- Calibrate the meter. Perform regular calibration to ensure that the meter is measuring accurately. Calibration can be done using a known flow standard or using the manufacturer's recommended procedure.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.