Professional colorimeter for sale, 4mm/8mm aperture, dual viewing angle, a variety of light sources and color variables, in line with a variety of colorimetric data, to meet the measurement needs.

USB/Blue Tooth

- Universal USB interface and Bluetooth 4.0 wireless transmission ensure flexible connectivity for the color spectrophotometer.

- More convenient data transfer makes the handheld color meter easier to use in various testing environments.

Large color screen

- The colormeter is equipped with a 3.5-inch color touchscreen, offering smooth and responsive operation.

- It provides a more intuitive and clear display interface, making the portable colorimeter easier to use and read.

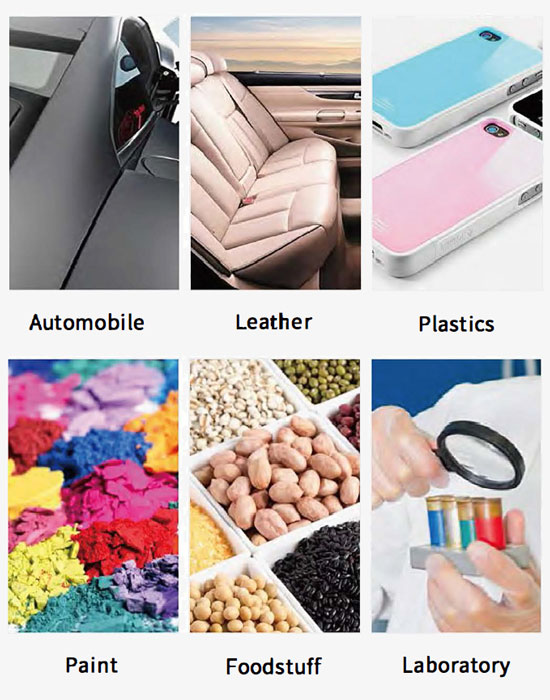

Application

The colorimeter can easily achieve accurate color transmission and can also be used as precision color testing equipment. It is widely used in plastic, electronics, paint, ink, textile and garment, printing and dyeing, printing paper, automotive, medical, cosmetic, food industries, research institutes, schools, and laboratories.

| Model | SISCO-CM-YS3020 |

| Optical Geometry | Reflect: di:8°, de:8°(diffused illumination, 8-degree viewing angle) |

| Integrating Sphere Size | 48mm |

| Light Source | Combined LED Light |

| Spectrophotometric Mode | Concave Grating |

| Sensor | 256 Image Element Double Array CMOS Image Sensor |

| Wavelength Range | 400-700nm |

| Wavelength Interval | 10nm |

| Semiband Width | 10nm |

| Measured Reflectance Range | 0-200% |

| Measuring Aperture | Customized Aperture: 8mm/4mm/1x3mm |

| Specular Component | SCI&SCE |

| Color Space | CIE Lab, XYZ, Yxy, LCh, CIE LUV, Hunter LAB |

| Color Difference Formula | ΔE*ab, ΔE*uv, ΔE*94, ΔE*cmc(2:1), ΔE*cmc(1:1), ΔE*00v, ΔE(Hunter) |

| Other Colorimetric Index | WI(ASTM E313, CIE/ISO, AATCC, Hunter), YI(ASTM D1925, ASTM 313), TI(ASTM E313, CIE/ISO),Metamerism Index MI, Staining Fastness, Color Fastness, Color Strength, Opacity, 8° Glossiness |

| Observer Angle | 2°/10° |

| Illuminant | D65, A, C, D50, D55, D75, F2, F7, F11 |

| Displayed Data | Spectrogram/Values, Samples Chromaticity Values, Color Difference Values/Graph, PASS/FAIL Result, Color Offset |

| Measuring Time | 2.6s |

| Repeatability | MAV/SCI: ΔE*≤0.05 |

| Inter-instrument Error | MAV/SCI: ΔE*≤0.2 |

| Measurement Mode | Single Measurement, Average Measurement |

| Locating Method | Camera View Finder Locating |

| Battery | Li-ion battery. 5000 measurements within 8 hours |

| Dimension | 184*77*105mm |

| Weight | 600g |

| Illuminant Life Span | 5 years, more than 3 million times measurements |

| Display | 3.5-inch TFT color LCD, Capacitive Touch Screen |

| Data Port | USB/RS232 |

| Operating Environment | 0~40℃, 0~85%RH (no condensing), Altitude<2000m |

| Storage Environment | -20~50℃, 0~85%RH (no condensing) |

Note: The user can perform black-and-white calibration through the standard black-and-white box of the instrument and refer to the user manual to complete the calibration independently.

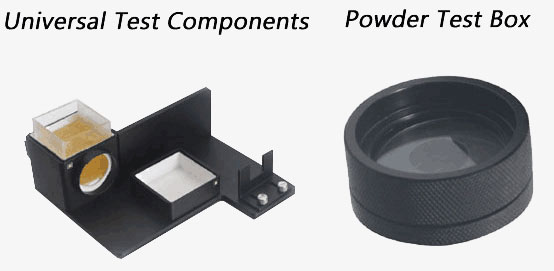

Color Spectrophotometer Accessories

1. Universal Test Components

Features: Powerful accessory with high sensitivity which is used to measure liquid, paste and powder.

Dimension: L*W*H=190x190x85 mm

2. Powder Test Box

Features: Easy to use; Focus on measuring powder.

Dimension: ø50X25mm

Packing List

- 1 x Spectrophotometer

- 1 x Power adapter

- 1 x Manual

- 1 x Data cable

- 1 x Built-in lithium battery

- 1 x CD (including management software)

- 1 x Black and white correction box

- 1 x Protection cap

- 1 x Universal test module (Optional match)

- 1 x Powder test box (Optional match)

Q1: How does a colorimeter work?

A1: Colorimeters rely on the concept of the Beer-Lambert law, which assumes that the absorbance of a substance is proportional to its concentration. For example, the higher the concentration of a solution, the higher the absorbance reading. Many chemical and biological experiments are based on this concept. To obtain a Beer's law curve, several standards (solutions of known concentration) are prepared and their absorbance values are determined using a colorimeter.

Q2: What is colorimetry?

A2: A colorimeter is a device that measures light absorbance (how much light is absorbed) and light transmission (how much light passes through) in a liquid by analyzing the intensity of the color.

Q3: What are the limitations of a colorimeter?

A3: One limitation of chemical colorimeters is that differences in certain substances may lead to inaccurate test results. According to Global Water Instrumentation, because these differences are different for each substance, a chemical colorimeter alone is not a completely foolproof testing device.

Tips: How can a portable colorimeter improve the color fastness of silk?

A portable colorimeter can help you improve the color fastness of silk by improving your manufacturing process and testing the durability of your textiles under specific environmental conditions. When processing raw silk with mordants and fabric dyes, you can first test the fabric for optimal color in sunlight, rubbing, and washing. By testing dyed silk test samples with a spectrophotometer, you will see how quickly your product fades under these conditions and you can optimize the mordant and dye formulation to improve color fastness.

The portable colorimeter will set the initial color standard for your product (the color of your product when it is first dyed) and you can then compare future measurements to this standard. For example, if you dye a silk sample and set the dye with aluminum mordant, you may find that the sample begins to fade after five washes. In response, you can use an iron mordant and apply your silk to a polymer film to improve fastness. To test whether these changes have a positive impact on the color fastness of the silk, you can wash the sample five times and see if it improves color retention. In addition, once you have improved the manufacturing process and dye formulation, you can test future silk products to ensure they are color consistent from batch to batch.

The sisco colorimeter requires only a small number of silk samples to test for colorfastness and color consistency, making it a cost-effective solution for manufacturers of textiles such as silk. By using a spectrophotometer to identify the most durable dyes and mordants, you will greatly improve the quality of your silk products and make the most of your limited time and resources.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.