Small portable ammonia gas detector is easy to carry and read. It is a handheld NH3 gas detector that has optional measurement ranges of 0-50ppm, 0-100ppm, 0-200ppm, 0-500ppm, etc. The gas detector provides ammonia (NH3) gas leak monitoring with a high-accuracy sensor and audible and visual alarms.

Gas detectors can detect ammonia (NH3) quickly

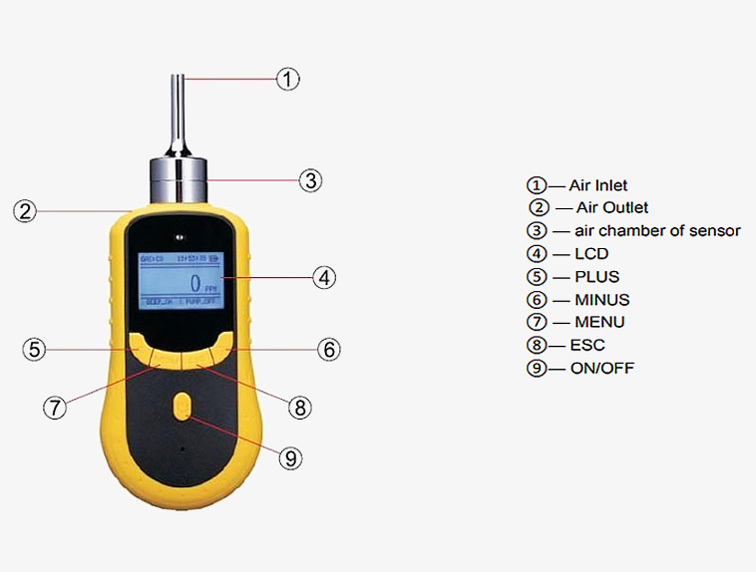

- sisco portable ammonia (NH3) gas detector has an LCD dot matrix display to directly read out the gas type, unit, concentration, local time, etc.

- English/Chinese operations are supported.

- Gas concentration unit PPM and mg/m3 can be shifted quickly.

- Built-in micro-sampling pump, 10 grades of suction are available.

Explosion-proof certification.

USB interface to transfer data at high speed

- The handheld ammonia detector can download and print the stored data (optional).

- There is no need for personnel to manually record data in real-time, and the data is automatically stored in the instrument.

- Historical data can be viewed on the instrument or downloaded to a computer.

- USB interface, fast and convenient charging.

Details

Applications

sisco portable ammonia (NH3) gas detector with a built-in micro pump is widely used in refrigerated spaces, liquid ammonia tank storage areas, laboratories, livestock farms, sewage treatment plants, denitrification chemical industry, etc. to monitor the leakage of NH3 gas and issue an alarm to protect human and animal.

| Model | GD200-NH3 |

| Sampling Method | Pumping suction, flow rate can be up to 750ml/min |

| Detection Principle | Electrochemistry |

| Gas | Ammonia (NH3) |

| Range (Optional) * | 0 to 10ppm, 0 to 20ppm, 0 to 50ppm, 0 to 100ppm, 0 to 200ppm, 0 to 500ppm, 0 to 1000ppm, 0 to 2000ppm, 0 to 5000ppm |

| Resolution | 0.01ppm (0-10/20/50ppm), 0.1ppm (0-100/200ppm), or 1ppm (0-500/1000/2000/5000ppm) |

| Accuracy | ≤±3% F.S. |

| Response Time | ≤10s |

| Repeatability | ≤±1% |

| Recovery Time | ≤10s |

| Linearity Error | ≤±1% |

| Zero Shift | ≤±1% (F.S./year) |

| Data Logging (Optional Function) | High speed data transmission by USB, available for data downloading and printing (The built-in IC card has about 2G memory, which can record 100,000 sets of data.) |

| Alarms | Sound, light and vibration |

| Display | LCD dot matrix display |

| Language | Chinese/English |

| Battery | 3.7V rechargeable lithium battery, 3.7 Watt (Charger included: Input AC 100-240V 50/60Hz with optional USA, Europe or UK plug) |

| Operating Time | 100h (Pump off) |

| Communication | Mini USB interface supports standard MODBUS communication protocol |

| Explosion-proof Grade | Ⅱ 2G Ex ia Ⅱ CT4 Ga |

| Case Material | ABS+PC |

| Protection Grade | IP66 |

| Certification | CE, ATEX (Standard: EN IEC 60079-0:2018, EN 60079-1:2014) |

| Operating Temperature | -20℃~50℃ |

| Operating Humidity | 0~95%RH (non-condensing) |

| Operating Pressure | 0.8~1.2bar |

| Dimension | 205*75*32mm |

| Weight | 300g |

| Warranty | 12 months |

| Extension Probe | About 480mm (Total Length), About 300mm (Probe Head) |

| Accessories (Optional) | Calibration kit - gas pressure regulator (calibration gas cylinder NOT included)

|

Note:

* If you need an NH3 gas detector with other measuring ranges unlisted in the above table, please inform us of your operating environment to help you choose an appropriate one for your application.

* Other portable gas detectors are also provided, you can refer to SISCO Gas Detector Catalog to get the specific gas type and measurement range. If you have any questions, please feel free to contact us.

Packing List:

- 1 × NH3 Gas Detector

- 1 × Carrying Case

- 1 × AC Adapter

- 1 × User Manual

Gas Detector Catalog & User Manual

SISCO Gas Detector Catalogue

SISCO Gas Detector Catalogue SISCO GD200 Portable Gas Detector User Manual

SISCO GD200 Portable Gas Detector User Manual SISCO GD300 Online Fixed Gas Detector User Manual

SISCO GD300 Online Fixed Gas Detector User Manual SISCO GD400 Explosion Proof Portable Gas Detector User Manual

SISCO GD400 Explosion Proof Portable Gas Detector User Manual SISCO GD500 Handheld Multi Gas Detector User Manual

SISCO GD500 Handheld Multi Gas Detector User Manual SISCO GD600 Multi Gas Analyzers User Manual

SISCO GD600 Multi Gas Analyzers User Manual SISCO Gas Detector Communication Protocol V1.0

SISCO Gas Detector Communication Protocol V1.0 SISCO Single Stage Pressure Regulator User Manual

SISCO Single Stage Pressure Regulator User Manual SISCO Gas Detector Data Downloading Operation Instruction

SISCO Gas Detector Data Downloading Operation Instruction

Gas Detector Software

Q1: What is a gas detector?

A1: A gas detector is an instrument for gas leakage concentration detection, including a portable gas detector, handheld gas detector, fixed gas detector, online gas detector, etc.

Q2: What does a gas detector detect?

A2: Combustible gases: Natural gas (methane), liquefied gas, coal gas (hydrogen), acetylene, pentane, alkynes, acetone, toluene, alcohols, hydrocarbons, light oil, etc.

Toxic gases: Carbon monoxide, hydrogen sulfide, ammonia, chlorine, oxygen, phosphine, sulfur dioxide, hydrogen chloride, chlorine dioxide and other toxic and harmful gases.

Q3: What is ppm of gas detector?

A3: Parts per million or "ppm" is often used as a fractional measure of concentration. For example, a methane (molecular) concentration of 2% means that 2 out of every 100 air molecules are methane. Likewise, a methane concentration of 2 ppm means that 2 out of every 1 million air molecules are methane.

Tips: The Advantages of Portable Gas Detector

- Small size, easy to carry, good quality and low price Portable gas detectors are usually small in size, so they are very convenient to carry and can be used at any time. In addition, high-quality portable gas detectors mainly use high-performance sensors, and high sensitivity is its most significant feature. This portable gas detector can visually display the gas concentration on site, and the standby time is longer than other products of the same type.

- Start-up detection, no need to set parameters. Before the factory leaves the factory, the parameters and values in the portable gas detector have been set, and the customer only needs to start the detection.

- Strong adaptability and a wide range of applications. The gas detectors can also be used in places that people cannot enter or cannot reach. Equipped with an external pump, this avoids the danger of letting the staff go to the detection first. The design of the pump extension pipe can be used in places such as cold rooms, refrigeration workshops, tunnels and other closed places where toxic gas leaks. In addition, the portable gas detector also adopts a waterproof, dustproof and explosion-proof design, and cooperates with a replaceable in-line gas sensing module, making it an ideal tool for safety detection on the job site today.

- Simple calibration steps General professional portable gas detectors have the characteristics of simple calibration steps. During the detection process, technicians only need to use the magnetic programming tool to start the calibration process. The detector will automatically start calibration as soon as the gas is supplied, and if the signal has started to be in a relatively stable state, the combustible gas detector will record the initial data and prompt the technician to disconnect the gas source.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.