A surface tension meter is a scientific instrument used to measure the surface tension of liquids. Surface tension refers to the cohesive force at the surface of a liquid that causes it to behave like a stretched elastic sheet. Accurate surface tension measurement is crucial in formulation, quality control, and research, helping manufacturers optimize product performance and stability.

LCD Display

- One of the primary benefits of an LCD display in surface tension meter is its ability to present real-time measurements in a clear and organized manner. This real-time feedback allows users to monitor experiments instantly, make quick decisions, and detect any inconsistencies during testing.

- LCD screens are designed for excellent visibility, even in various lighting conditions. Backlit displays ensure that readings remain visible in both dim and bright environments, reducing the chances of misreading data.

- Compared to analog dials, an LCD display supports precise digital readouts, this is especially beneficial in applications requiring high sensitivity, such as in chemical, pharmaceutical, and cosmetic industries.

Surface Tension Meter Adopts Built-in Printer

- Interfacial tension meter adopts a built-in printer is the ability to immediately print results after each test. This real-time data output reduces the risk of human error in manual data recording and ensures that all readings are accurately documented, enhancing the reliability of the data.

- By eliminating the need for manual transcription or external data transfer, a built-in printer enhances workflow efficiency. Operators can focus on testing rather than switching between instruments or input devices.

Applications

SISCO automatic surface tension meter is an essential analytical instrument used to measure the surface tension of liquids. It finds applications across various industries due to its ability to determine the intermolecular forces at liquid interfaces. One major field is pharmaceuticals, where it helps optimize drug formulations, particularly in emulsions, suspensions, and aerosols. In the cosmetic industry, it ensures stability and effectiveness of creams, lotions, and shampoos by analyzing surfactants and emulsifiers.

Chemical Industry

Printing Industry

Environmental Science

Pharmaceutical Industry

| Model | SISCO-TM-ZL-3 |

| Measuring Range | 0-200mN/m |

| Testing Method | Platinum ring method |

| Accuracy | 0.1% (test result) ±0.1mN/m |

| Precision | 0.1mN/m |

| Sensibility | 0.1mN/m |

| Voltage | 110V-220V |

| Maximum Power Dissipation | 20W |

| Suit Ambient Temperature | 10 ℃-30 ℃ (25 ℃ the best) |

| Suit Ambient Humidity | ≤85% RH |

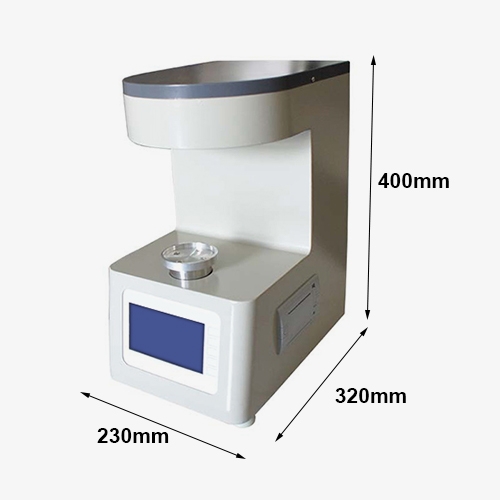

| Dimension | 230*320*400mm |

| Net/Gross Weight | About 8kg/15kg |

Dimension:

Q1: How to maintain a surface tension meter?

A1: To maintain a surface tension meter, regular cleaning and proper handling are essential. After each use, clean the measuring parts, such as the platinum ring, with distilled water or appropriate solvents to remove any residue. Store the meter in a clean, dry environment to prevent corrosion or contamination. Avoid exposing it to extreme temperatures or direct sunlight.

Q2: What units are used to express surface tension?

A2: Surface tension is commonly expressed in units of force per unit length. The standard unit is newtons per meter (N/m) in the International System of Units (SI). This unit indicates the force (in newtons) acting along a line of one meter length at the liquid surface.

Q3: What industries commonly use surface tension meters?

A3: Surface tension meters are commonly used in a wide range of industries to measure the surface or interfacial tension of liquids. In the chemical and pharmaceutical industries, they help in formulation development and quality control. The cosmetic and personal care sectors use them to optimize emulsions and surfactants. In the petroleum industry, they're vital for fuel and lubricant analysis. Food and beverage manufacturers use them for controlling liquid properties in production.

Tips: What factors affect the accuracy of surface tension meter measurement?

Several factors affect the accuracy of interfacial tension meter measurements. Temperature plays a critical role, as surface tension varies with temperature changes; thus, precise thermal control is essential. Environmental conditions like humidity and air currents can influence drop formation and measurement stability. Operator technique, such as inconsistent sample handling or timing, may also introduce variability.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.