Economical price digital weighing indicator with printer for sales. The weighing indicator can set the tracking range to zero. In high-precision weighing indicators, the DC power socket comes with anti-connect and anti-short circuit protection along with a strong anti-disturbance function.

Digital weighing indicator with a 6-digit 0.8-inch LED display

- The bright LED display ensures easy reading of weight data, even in low-light or industrial environments.

- The 7-digit format provides accurate weight measurements for both small and large loads.

- The 0.8-inch display offers a compact solution, ideal for systems where space is limited.

- The simple, bright display allows for quick and efficient operation, enhancing workflow efficiency.

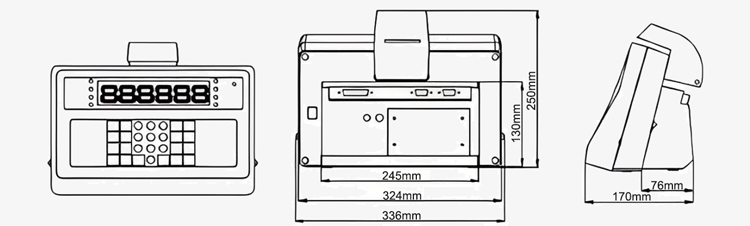

Dimension

Applications

SISCO weighing indicators are widely used for accurate weight measurement in various industries. They are essential in warehouses for inventory management, in supermarkets for weighing products and pricing, in logistics and transportation to prevent overloading, and at ports for weighing containers and ensuring safe cargo handling. These devices enhance efficiency and precision across these applications.

Logistics and Transportation

Warehouse

Wharf

Supermarket

| Model | SISCO-WI-GSI201+P-1 |

| Accuracy | 1/3000 |

| Display Accuracy | 113000~1/30000 |

| Sensor Excitation voltage | 5V DC |

| Supply Voltage | 100~240VAC 50HZ |

| Battery | Lead-acid battery·6V/4AH (Not Included) |

| Maxnumber of Connected Load Cell | 350Ω~8pcs or 700Ω~16pcs |

| Operating Temperature Range | 0℃~40℃ |

| Storage Temperature and Humidity | -25℃~55℃, ≤85%RH |

| Communication | Standard: 2pcs RS232 ports, optional RS485 |

| Baud Rate | 1200/2400/4800/9600 |

| Weight | 5kg |

Q1: What is a weighing indicator?

A1: A weighing indicator is a device used in conjunction with weighing scales or load cells to display and process weight measurements. It receives electrical signals from the load cells, converts them into readable weight values, and displays the information on a screen. Depending on the model, weighing indicators can offer additional features like data storage, connectivity for data transfer, and advanced weighing functions such as tare, counting, and totalizing. They are commonly used in various industries, including logistics, warehousing, retail, manufacturing, and more, to ensure accurate weight readings and efficient process management.

Q2: Can weighing indicators be used with different types of scales?

A2: Weighing indicators can be used with a variety of scales, making them versatile tools in numerous industries. They are compatible with different types of scales, such as platform scales for heavy-duty industrial use, bench scales for smaller applications like retail or laboratories, floor scales for bulk weighing in warehouses, and weighbridges for weighing large vehicles in logistics and transportation. Additionally, they can be used with hopper and tank scales in manufacturing and crane scales for suspended loads in construction or shipping. This flexibility allows Weighing Indicators to meet diverse weighing needs across multiple sectors.

Q3: How do weighing indicators communicate with other devices?

A3: Many weighing indicators support communication protocols like RS232, RS485, Ethernet, USB, or wireless options. This allows them to connect to computers, printers, or control systems for data logging or remote monitoring.

Tips: How does a weighing indicator work?

A weighing indicator works by converting the signals from a connected scale or load cell into a readable weight measurement. Here’s a breakdown of how it operates:

- Load Cells: The weighing system typically includes load cells, which are sensors placed under or within the scale. When an object is placed on the scale, it exerts force, causing slight deformations in the load cells.

- Signal Conversion: The load cells convert this mechanical force into electrical signals. These signals are usually very weak and require amplification.

- Amplification and Signal Processing: The weighing indicator amplifies the signal from the load cells and processes it. It may also filter out noise or interference to ensure the accuracy of the weight data.

- Analog to Digital Conversion: Once processed, the analog electrical signal is converted into a digital value by the indicator. This digital value represents the weight of the object on the scale.

- Display: The digital weight value is then displayed on the indicator's screen, such as an LED or LCD display, for easy reading. Advanced indicators may also allow further functions like tare (zeroing the weight), unit conversion, or totalizing multiple measurements.

In summary, the weighing indicator takes the electrical signals from the load cells, processes and converts them, and displays the corresponding weight on the screen.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.