high voltage alarm for sale, voltage level display 380V~220kV, LCD backlight display, linear transmission distance of 30 meters, connected to the computer via USB to view data, widely used in substations, power plants, fire departments and industrial and mining enterprises.

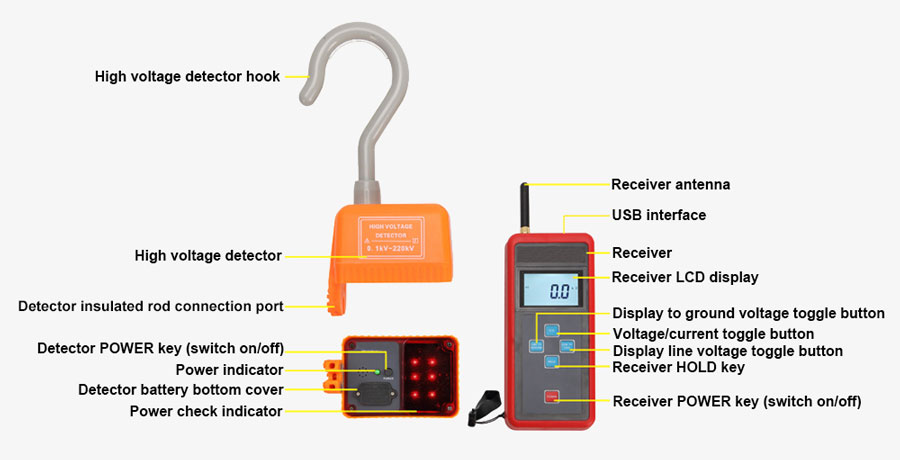

Hook design is more labor-saving

- Probe hook diameter φ50mm.

- Multi-voltage level display, 380V~220kV.

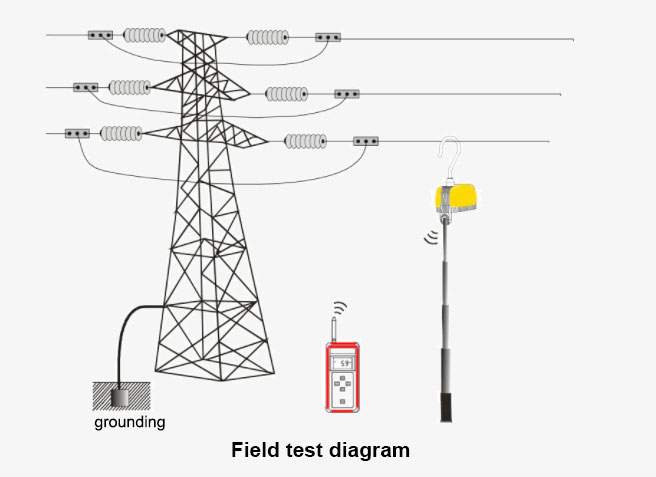

- Hang the detector on the high-voltage line with an insulated pole to check the electricity and display the voltage and current of the high-voltage line.

Outstanding sound and light warning

- Red light, 6 flashing lights, loud warning.

- 30 meters wireless transmission, direct view of the detected data, USB can be connected to a computer to read real-time and historical data.

Application

Wireless high-voltage electroscope (with voltage indication) is specially manufactured for high-voltage transmission line inspection, high-voltage transmission line-to-ground voltage, induced voltage test and current test. High-voltage electroscopes are widely used in electric power, railways, industrial and mining enterprises and other near-electrical workplaces.

| Model | SISCO-ETCR1800A |

| Function | Wireless high voltage inspection, high voltage line voltage test |

| Voltage Level Display | 380V, 6.6kV, 10kV, 35kV, 66kV, 110kV, 220kV |

| Display Range of Voltage to Earth | 0.1kV~150kV (to earth voltage) |

| Check Voltage Range | 380V~220kV |

| Ground Voltage Display Accuracy | ±15%rdg±5dgt |

| Probe Length | 110mm (According to the site conditions to replace the probe hook or probe) |

| Wireless Frequency | 433MHz |

| Wireless Transmission Distance | 30m straight-line transmission distance |

| LCD Size | 47mm X 28.5mm (with backlight) |

| Electricity Indication | the detector has a sound and light indication function, red double flashing light indication, and "beep - beep - beep" beeping sound when checking electricity |

| Display Rate | 2 times/second |

| Data Storage | 99 groups (power failure or battery replacement will not lose data) |

| Automatic Shutdown | About 10 minutes of power on the instrument will automatically shut down |

| Low Battery Voltage Indication | When the detector battery voltage drops below 7.2V to 0.1V, the green power indicator flashes. When the receiver voltage is lower than 4.8V to 0.1V, the low battery voltage indication low symbol "- +" to remind to replace the battery. |

| Rated Current | Detector: 75mA max, receiver: 35mA max |

| Probe Hook Aperture | φ50mm |

| Size | Receiver: 78mm X 165mm X 42mm, detector 300mm X 237mm X 85mm |

| Mass | Approx. 660g (including battery), total mass approx. 6kg (including accessories) |

| Insulation Rod Length | About 4500mm |

Packing List

- 1 x Detector

- 1 x Receiver

- 1 x Probe

- 1 x Probe hook

- 1 x Probe telescopic Insulation Rod

- 1 x USB communication cable

- 4 x Alkaline dry battery

- 1 x 9V6F66 battery

- 1 x Toolkit

Detail

Wiring Diagram

Q1: What is the high voltage tester used for?

A1: A high voltage tester is widely used in substations, power plants, fire departments, industrial and mining enterprises, electrician maintenance departments for power detection and field electrician work, etc.

Q2: What is a high-voltage electroscope?

A2: High-voltage electroscope is a tool used to check whether high-voltage lines and power equipment are live, and is a basic safety tool commonly used in

substations. The high-voltage electroscope is used to check whether the line or equipment is charged, the purpose is to ensure personal safety.

Q3: How to divide the high voltage tester level?

A3: According to the applied voltage level, a high voltage tester can be divided into: 0.1-10KV detector, 6KV, 10KV detector, 35KV, 66KV detector, 110KV, 220KV detector, and 500KV detector.

Tips: How to detect high voltage with a wireless high voltage detector?

When the bare conductor voltage exceeds 60kV, non-contact power testing, the detector gradually closes to the wire, without touching the wire to complete the power test. For the bare wire below 60kV, the detector can be hung on the line contact test. Whether it is zero line, fire line, ground, high-voltage transmission line, or metal conductor, as long as there is electricity, maybe direct transmission of electricity, may also be insulation damage caused by leakage, the full intelligent detector can sense its electric field, and emit a beeping sound, the stronger the electric field near the wire, the beeping sound more urgent, warning of electricity.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.