Linear scale is a high-precision sensor used to measure and monitor mechanical motion and is widely used in CNC machine tools, machining centers, and other fields. Installing a linear scale is a critical step in ensuring that equipment operates properly and maintains accuracy. This article will detail the steps for installing linear scale to ensure that users can complete the installation process correctly and efficiently.

Preparing for Installation

Confirm equipment compatibility: Before purchasing linear scale, it is important to confirm its compatibility with the target equipment. Check the specifications of the linear scale and the technical requirements of the equipment to ensure that they will work together.

- Check Linear Encoder Integrity: Before installation, double-check the packaging of the linear encoder to ensure that there are no shipping damages or missing parts. If there are any problems, contact the supplier to resolve them.

- Prepare Materials: Linear scale, mounting brackets, screws and nuts, cable installation tools (wrenches, screwdrivers, etc.)

- Preparation of Working Environment: Ensure that the installation environment is clean and tidy to prevent dust or other impurities from affecting the performance of the linear scale. The working environment should have good light and ventilation conditions.

- Safety Measures: When carrying out the installation work, be sure to follow the safety regulations, and wear the necessary protective equipment to ensure that the work area is safe and free of hidden dangers.

Installation Method

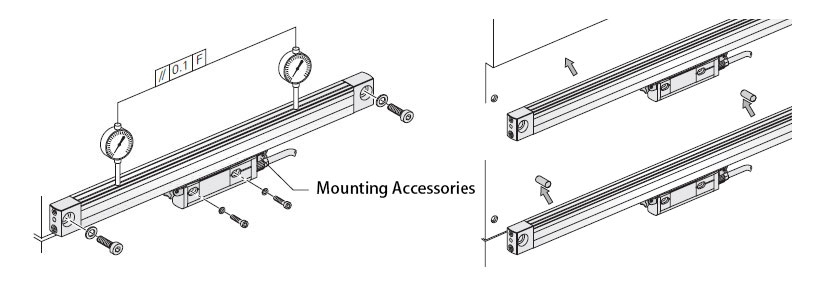

Linear scale installation is usually divided into vertical installation and horizontal installation of two kinds, the specific choice depends on the application scene.

Vertical Installation: Determine the linear scale installation position, and use a level to ensure that the installation position level. Use the bracket to fix the linear scale to the mounting position. Use screws and nuts to tightly attach the linear scale to the bracket.

Horizontal Mounting: Determine the mounting position of the linear scale and use a spirit level to ensure that the mounting position is vertical. Use the bracket to secure the linear scale to the mounting position. Use screws and nuts to tightly attach the linear scale to the bracket.

Installation Steps

- Determine the Mounting Position: Determine the best mounting position according to the needs of the equipment and the measuring range of the linear scale. Considering the length and mechanical structure of the linear scale, make sure that the mounting position is not affected by external factors such as vibration and temperature changes.

- Clean the Mounting Surface: Clean and prepare the mounting surface at the mounting location to ensure that it is free from dust, oil, and other substances. Use appropriate cleaners and tools to keep the mounting surface flat and clean.

- Mounting Base: Mount the base of the linear encoder in the pre-prepared position. Use appropriate screws and nuts to tighten the base to ensure its stability and firmness.

- Mounting the Linear Scale: Install the high accuracy linear scale along the base to ensure accurate alignment with the base. Using the installation tools provided by the manufacturer, gradually fix the linear scale to the base, taking care not to over-tighten or over-loosen it.

- Connecting the Cable: Connect the linear scale cable to the appropriate connector on the device. Ensure that the connection is firm to avoid loosening or disconnection during movement.

- Adjustment and Testing: After the installation is complete, proceed to the adjustment and testing steps. Use the adjustment tool to adjust the position and angle of the linear scale to ensure that it is in line with the mechanical movement trajectory. Subsequently, functional testing is performed to ensure that the measurement accuracy and stability meet the requirements.

Common Problems

- Improper Choice of Mounting Position: If the mounting position is not chosen correctly, the measurement accuracy of the linear scale may be affected. Re-evaluate the mounting position and make the necessary adjustments.

- Unstable Connection: If the cable connection is unstable, this may lead to interruptions or errors in data transmission. Check the connection to ensure good contact between the plug sockets.

- Insecure Base: If the base is not securely mounted, this may cause the linear scale to loosen during movement. Check the fixing screws of the base to ensure that they are as tight as required.

- Inaccurate Adjustment: If the adjustment is inaccurate, it may lead to measurement deviation. Read the adjustment procedure carefully and use the correct adjustment tool to ensure the accuracy of the adjustment.

Installation Precautions

- Bracket Selection: The bracket should not be too long but as wide and thick as possible to keep the intrinsic frequency as high as possible, the bracket should preferably be one-piece, preferably without weldments and bolt fasteners, the bracket should be mounted on a large, smooth and flat surface.

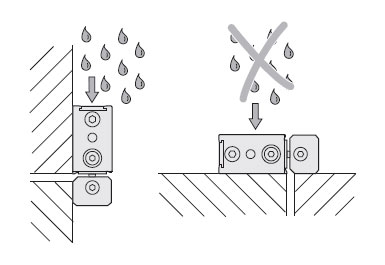

- Dust and Waterproof: During installation, ensure that dust and moisture are prevented from entering the linear scale to avoid affecting its normal operation. The linear scale should be mounted on a rigid surface with no interfering objects on the mounting surface.

- Avoid Shocks: Avoid shocks to the linear scale during installation and use to prevent damage. Do not install the linear scale on shock animals or in areas where vibrations are amplified. For simple wiring, mounting blocks should be fastened to non-moving elements to avoid stressing the cable.

- Regular Maintenance: Follow the manufacturer's maintenance recommendations for regular cleaning and inspection of the linear scale to ensure long-term stable operation.

- Temperature Environment: Try to use the linear scale within the temperature range specified by the manufacturer to avoid extreme temperatures affecting the equipment. Avoid installing the linear scale near a strong magnetic field, so that the magnetic field will not interfere with the measurement accuracy.

Installing a linear scale is a precise task that requires careful handling and accurate adjustment. By performing the above steps correctly, you can ensure that the linear scale will work optimally in your equipment and improve the measurement accuracy and stability of your mechanical system. If you encounter problems during installation, it is recommended that you contact your supplier or technical support team for professional help and guidance. sisco store is a reliable online store specializing in the sales and technical service of portable detectors, meters, testers, and scales, engineers and technicians can provide you with professional help in the installation and use of your equipment, we look forward to your inquiry and mutual future cooperation.