Intelligent PID controller with self-tuning function, automatically calculates the best P, I, and D three parameters to adapt to the control environment, while supporting a variety of sensors such as CU50/PT100/K/E/J/T/S temperature sensors and 4-20 mA /0-10mA/1-5v/0-10v/0-5v current signal.

Accurate and stable measurement

- The input adopts a digital calibration system with accurate and stable measurement, supporting a variety of thermocouple and RTD specifications with the highest resolution of 0.01°C.

- Adopt an advanced intelligent PID adjustment algorithm, no overshoot, with a self-tuning (AT) function, the central control output positive and negative control can be set arbitrarily.

Humanized design, easy to learn and use

- Anti-interference performance meets the requirements of electromagnetic compatibility (EMC) in harsh industrial conditions.

- The sisico temperature controller adopts automatic zeroing and digital calibration technology for maintenance-free instrumentation and can be corrected by parameters if the measurement is out of tolerance during calibration.

Application

Temperature controllers are widely used in various home appliances, such as water dispensers and heaters. The refrigerator uses a temperature controller to adjust the temperature to keep food fresh. The temperature controller can always control the temperature inside the refrigerator within a specific range. When the temperature is higher than the specified range, the thermostat can automatically cool down.

| Model | SISCO-TCPD2 |

| Weight | 0.5kg |

| Dimension (Length*High*Depth) * | D1: 160*80*80mm with hole size 152*76mm; D2: 96*96*110mm with hole size 92*92mm; D3: 48*96*110mm with hole size 44*92mm; D4: 96*48*110mm with hole size 92*44mm; D5: 72*72*110mm with hole size 68*68mm; D6: 48*48*110mm with hole size 44*44mm; D7: Rail type 72*88*59mm |

| Supply voltage | 85V-240V AC or 24V DC, 50-60Hz |

| Working environment | Temperature: -10~60℃, humidity: ≤90%RH |

| Sampling period | 8 times/second; When set digital filter parameter FILt=0, response time≤0.5s |

| Accuracy | ±0.5%F.S ±1 digit |

| Resolution | ≤0.01℃ |

| Input signal * | I1. Temperature sensor: CU50 (-50.0~150.0℃), PT100 (-199.9~600.0℃), K (-50.0~1300℃), E (-50.0~700.0℃), J (-30.0~900.0℃), T (-199.9~400.0℃), S (-30.0~1600℃), R (-30.0~1700℃), WR25 (-30.0~2300℃), N (-30.0~1200.0℃) I2. Analog signal: 4-20mA, 0-10mA, 0-5V, 1-5V, 0-50mV, 10-50mV |

| Control mode | 1. On-off control; 2. PID control Need manually switch to another control mode. |

| Output mode * | O1: Relay output; O2: SSR output; O3: SCR output; O4: Transmitter output 4-20mA/0-10V |

| Alarm mode * | A1 Default mode: 1 alarm output; A2 Extension mode: 2 alarm outputs |

| Alarm | Upper limit, lower limit, upper deviation, lower deviation, in the deviation section, outside the deviation section |

| Programmable function | Subsection control, total 64 custom program segments (include 32 constant temperature segments and 32 warming segments) |

| Program segments modes | 1. Execution mode: Standby after execution; Skip to the first segment after execution and continue execution (loop execution). 2. Power-up mode: The current segment is automatically executed after power-up; The first segment is automatically executed after power-up; Waiting for user command after power-up. 3. Constant temperature segment time unit: minimum unit is minute; minimum unit is second. 4. The bottom window can be manually switched to display: The set value of current segment; The number of current segment; The running time of current segment. 5. Custom output alarm time after last segment finished (optional). |

| Additional power supply * | DC 24V for sensor of input signal I2 |

| Additional output mode * | RS: RS485/232 communication (MODBUS-RTU protocol); TS: 4-20mA/1-5V, 0-10mA/0-5V transmitter |

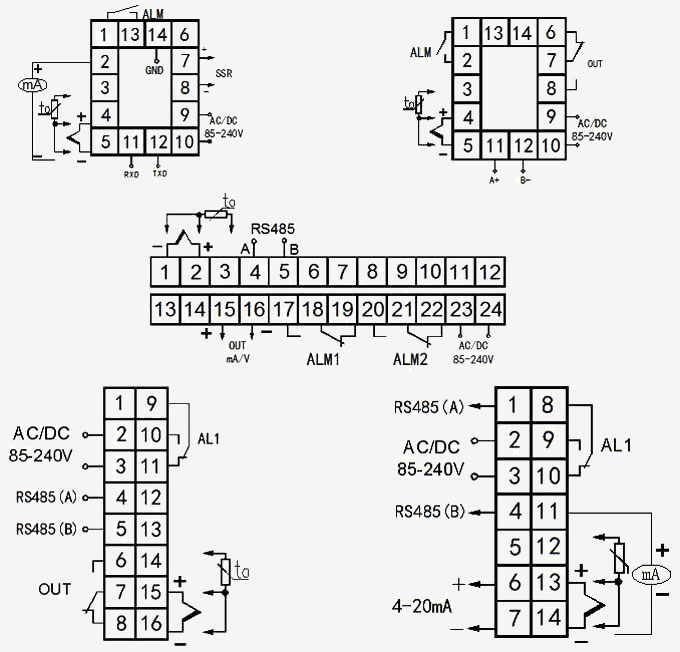

Programmable temperature controller wiring diagram

Q1: What is a temperature controller?

A1: A thermostat is a series of automatic control elements that generate certain special effects by physical deformation inside the switch according to the temperature change of the working environment, resulting in an on or off action, also called temperature control switch, temperature protector, temperature controller, or thermostat for short. Or through the temperature protector will be temperature to the temperature controller, temperature the controller issues a switch command, so as to control the operation of the equipment to achieve the desired temperature and energy-saving effect.

Q2: What is the working principle of a temperature controller?

A2: Its working principle is to automatically sample and instantly monitor the ambient temperature through the temperature sensor, and the control circuit starts when the ambient temperature is higher than the control setpoint, and the control return difference can be set. If the temperature is still rising, the over-limit alarm function is activated when it rises to the set over-limit alarm temperature point. When the controlled temperature can not

be effectively controlled, in order to prevent the destruction of the equipment can also stop the equipment to continue to run through the function of tripping. It is mainly used in various high and low-voltage switchgear, dry-type transformers, box-type substations, and other related temperature fields used in the electric power sector.

Q3: What is the temperature controller used for?

A3: Digital electronic temperature controller is a precision temperature detection controller, that can be digital quantitative control of temperature, temperature controller is generally used NTC thermal sensor or thermocouple as the temperature detection element.

Tips: What do ON and OFF in a temperature controller mean?

In the temperature controller, the ON/OFF control sets the parameter P to 0. The temperature controller compares the difference between the measured value (PV) and the set value (SV) and regulates the controlled object with the ON/OFF control. When the temperature is below the set lower limit parameter, the temperature turns on the heating unit and the unit runs at full power. When the temperature is above the set upper limit parameter, the thermostat turns off the heating unit and the heating stops completely. The temperature fluctuates slowly between the lower and upper limits. ON/OFF control temperature has fluctuations. The unit starts and stops frequently, but the control method is simple.