Three-phase digital energy meter with modular device for 35mm DIN rail mounting, measures active energy by means of the current between input and output. Internal integrated circuit is manufactured with precision SMT technology, with good electromagnetic interference resistance and stable performance.

Easy to use

- Large buttons for easy operation

- The operation interface is simple and easy to use

Smart metering chip

- Electronic measurement with high precision and small error

- Long-term use without adjustment

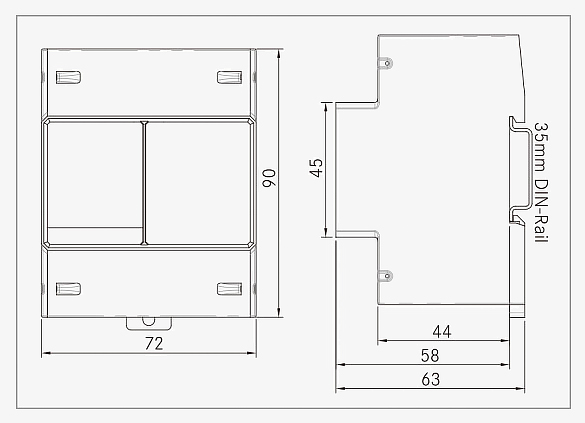

Dimension (unit=mm)

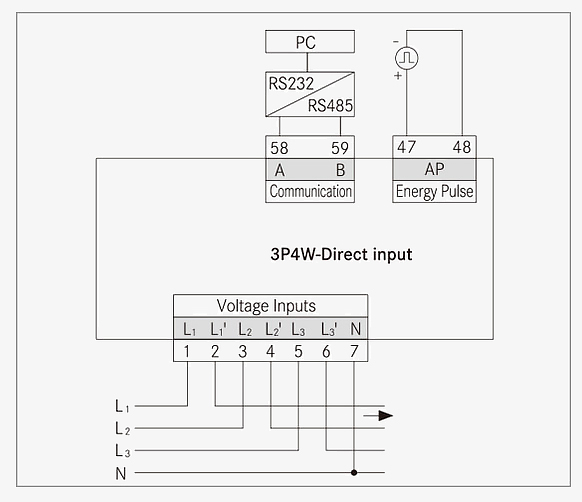

Wiring

Application

Digital energy meters also called advanced meters or smart meters, are intelligent devices that automatically record the user consumption of water and electricity. SISCO digital energy meter is widely used in rail, smart switch cabinet, intelligent buildings, smart factories and energy management systems.

| Model | SISCO-DTS1946-4P | ||||

| Accuracy Grade | Grade-1 accuracy for active energy | ||||

| Phase | Three-phase (4-wire) | ||||

| Number of Poles | 4P | ||||

| Rated Voltage | 3x230/400V AC | ||||

| Current Direct Input | 5(100)A | ||||

| Frequency | 50/60Hz | ||||

| Display Mode | LCD display | ||||

| Display Digits | 4 | ||||

| Energy Pulse | 1 active energy pulse output, pulse width (80±20%) ms | ||||

| Measurement Range | Voltage/Current/Active power/Power factor/Frequency | ||||

| RS485 Communication Interface | Modbus-RTU protocol, baud rate up to 9600bps | ||||

| IP Protection | IP54 (panel) /IP20 (case) | ||||

| Certificate | CE/ ISO/ MID | ||||

| Warranty Period | 12 months | ||||

| Dimension | 72*63*90mm | ||||

| Weight | 1.8kg | ||||

| Installation | Din rail 35mm | ||||

| Work Temperature | -10℃~55℃ | ||||

| Storage Temperature | -25℃~70℃ | ||||

Q1: What are the advantages of digital energy meter?

A1: The meter has protection against undesired input range. Hence the meter can be protected from overload or some of the fault or misuse. The auto polarity function can prevent problems from connecting the meter to a test circuit with some wrong polarity. Overall accuracy is increased due to digital readout.

Q2: What is the difference between a power meter and an energy meter?

A2: One major difference between a wattmeter and an energy meter is that the wattmeter measures electrical power in the circuit, whereas the energy meter measures total amount of energy consumed by the load.

Q3: What is the main function of an energy meter?

A3: An energy meter is an electrical device that measures the electrical power being consumed and this allows the energy consumed over time (by a residential building, a business, or an electrically powered device) to be determined.

Tips: How does an energy meter work?

When the electric energy meter is connected to the circuit under test, alternating current flows through the current coil and the voltage coil, and the two alternating currents generate alternating magnetic fluxes in their iron cores; Passing through the aluminum plate, an eddy current is induced in the aluminum plate; the eddy current is acted by a force in the magnetic field, so that the aluminum plate gets torque (active torque) and rotates. The greater the power consumed by the load, the greater the current passing through the current coil, the greater the eddy current induced in the aluminum plate, and the greater the torque that makes the aluminum plate rotate. That is, the magnitude of the torque is proportional to the power consumed by the load. The greater the power, the greater the torque, and the faster the aluminum disc turns. When the aluminum disc rotates, it is affected by the braking torque generated by the permanent magnet. The braking torque is opposite to the active torque. The magnitude of the braking torque is proportional to the rotational speed of the aluminum disc. The faster the aluminum disc rotates, the higher the braking torque. bigger. When the active torque and the braking torque reach a temporary balance, the aluminum disc will rotate at a constant speed. The electrical energy consumed by the load is proportional to the number of revolutions of the aluminum disc. When the aluminum plate rotates, it drives the counter to indicate the power consumption. This is the simple process of how the energy meter works.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.