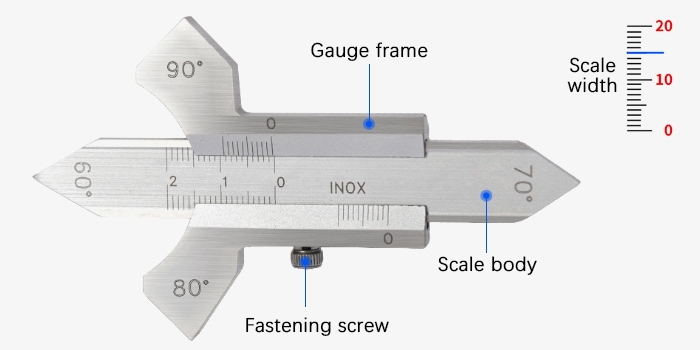

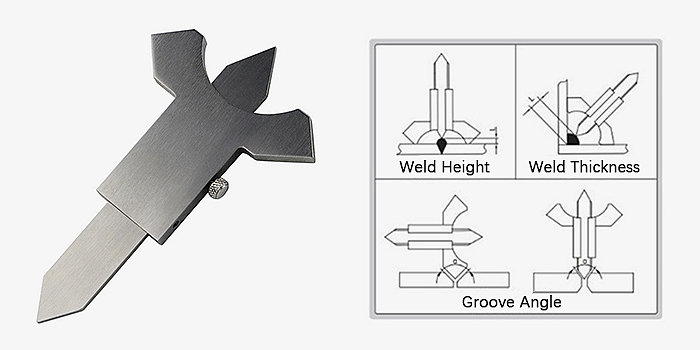

As a professional tool specifically designed for weld inspection, this vernier weld gauge incorporates the precise measuring principles of a vernier caliper. It allows for fast and accurate measurement of weld reinforcement height, weld width, throat thickness, and other critical dimensions. SISCO’s stainless steel vernier weld gauge features sharp, clearly marked scales and a seamless reading process, perfect for welding quality control in industrial and field environments.

High-Precision Readings & Versatile Applications

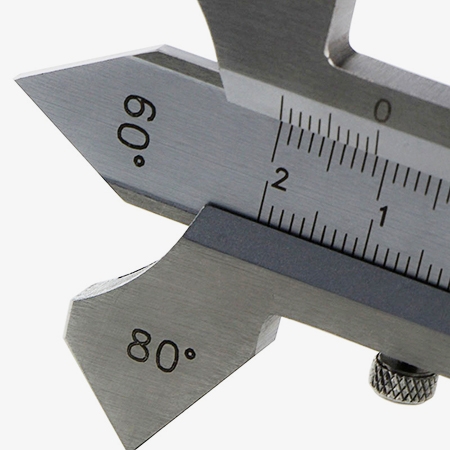

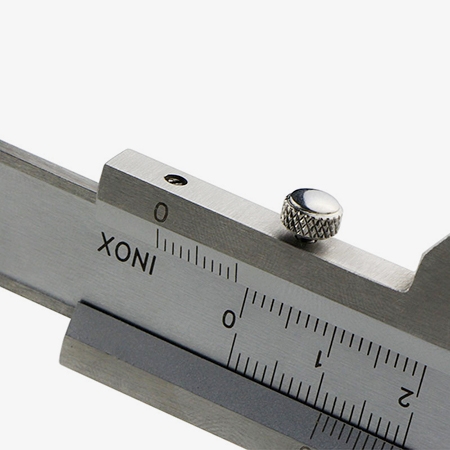

- Crystal-Clear Laser Markings: The scales on this vernier weld inspection gauge are created using advanced laser engraving technology. The finely etched lines are highly visible and easy to read, which ensures users can obtain accurate readings quickly, significantly boosting measuring efficiency.

- Multi-Angle Measurement Capability: Designed with multi-angle adaptability in mind, this vernier welding seam gauge easily adjusts to accommodate complex weld shapes and positions. It’s an ideal fit for precision welding inspection tasks in industries like aerospace, automotive manufacturing, and structural engineering.

Easy Adjustments & Rugged Durability

- User-Friendly Adjustable Nut: Equipped with an ergonomic adjustment nut, the weld measuring gauge allows for quick and accurate positioning with just a simple twist—no complicated steps required.

- Durable Stainless Steel Build: Constructed from premium stainless steel, this welding gauge offers excellent corrosion and wear resistance. It remains reliable even in harsh environments like offshore platforms or fabrication yards.

Applications

Weld gauges are widely used in various industries. In boiler manufacturing, they measure weld reinforcement, width, misalignment, and undercut depth to meet pressure part standards. In shipbuilding, they check fillet weld size, leg height, and assembly gaps to ensure hull strength. In oil pipelines, welding gauges assess groove angles and gap sizes to prevent welding defects and leaks. In industrial construction—such as bridges and pressure vessels—they provide accurate weld dimension data for process evaluation and quality control.

Shipbuilding

Oil Pipelines

Industrial Construction

Boiler Manufacturing

| Model | SISCO-WG-V |

| Material | Stainless Steel |

| Measuring Range | 0–20mm |

| Reading Value | 0.1mm |

| Resolution | 0.02mm |

| Measuring Accuracy | ±0.02mm |

| Net Weight | 100g |

| Craftsmanship | Precision ground finish, chrome-plated surface, laser-engraved scale |

| Application | Widely used in welding measurement fields |

Details

Q1: What types of weld measurements can the SISCO vernier weld gauge perform?

A1: The SISCO vernier weld gauge is designed for precision weld inspection and can measure several key parameters, including weld reinforcement height (weld cap), weld width, and throat thickness. Thanks to its 0–20mm measuring range and fine resolution of 0.02mm, this tool ensures highly accurate readings, making it ideal for quality control in pressure vessel fabrication, structural steelwork, and pipeline welding.

Q2: Is this weld gauge suitable for use in industrial environments?

A2: Yes, this weld measuring gauge is crafted from high-strength stainless steel with a chrome-plated surface, making it corrosion-resistant and highly durable. Its robust construction allows it to perform reliably in challenging environments such as oil fields, shipyards, and fabrication shops. The precision laser-etched scales remain legible even in dusty, oily, or humid conditions.

Q3: How do I ensure consistent accuracy when using the vernier weld gauge?

A3: To maintain measurement accuracy, ensure the gauge is clean and free from debris before each use. The adjustable nut allows for precise positioning of the scale, and the laser-engraved markings ensure visibility and consistency. Periodic calibration against a known standard is also recommended, especially in environments with high usage or temperature fluctuations.

Tips: How can I extend the lifespan of my vernier weld gauge in tough working conditions?

To maximize the longevity and accuracy of your vernier weld gauge, store it in its protective leather case when not in use to prevent physical damage and environmental exposure. After each use, wipe the surface clean to remove dust, oil, or metal residue that could affect the readability of the laser-etched scales. Avoid dropping or overtightening the adjustable nut, and periodically apply a light coat of anti-rust oil if used in humid or corrosive settings such as coastal areas or chemical plants. Proper care ensures the gauge remains a reliable tool in your welding quality assurance kit for years.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.