Our fan-type welding gauge is crafted from premium stainless steel with excellent strength and toughness. Advanced laser marking ensures precise and clear scale lines, allowing for millimeter-level accuracy. This weld gauge is a scientifically engineered structure, and its sleek, ergonomic design makes it comfortable to use and widely applicable in various welding scenarios.

Ergonomic and Safe Design for Comfortable Operation

- Rounded Edges for Safety: All edges of this welding gauge are smoothly rounded to prevent hand injuries during use. The safe edge design enhances the user experience while maintaining a refined appearance.

- Ergonomic Grip Handle: Designed with welders in mind, the welding gauge's grip adheres to ergonomic principles, providing a comfortable hold that reduces fatigue during extended inspection tasks and enhances work efficiency.

Durable Laser-Etched Stainless Steel Construction

- Laser-Etched for Long-Lasting Accuracy: This weld measuring gauge features precision laser-engraved markings on a stainless steel body, offering exceptional wear resistance. Even with prolonged use and frequent handling, the scale remains sharp and legible, ensuring reliable accuracy every time.

- Thickened Stainless Steel Body: Forged from thick stainless steel and treated with a strict heat-hardening process, the fan-shaped weld gauge provides enhanced strength and rigidity, extending its service life and ensuring stable long-term performance in demanding industrial environments.

Applications

Weld gauges are widely used in various industries. In boiler manufacturing, they measure weld reinforcement, width, misalignment, and undercut depth to meet pressure part standards. In shipbuilding, they check fillet weld size, leg height, and assembly gaps to ensure hull strength. In oil pipelines, welding gauges assess groove angles and gap sizes to prevent welding defects and leaks. In industrial construction—such as bridges and pressure vessels—they provide accurate weld dimension data for process evaluation and quality control.

Shipbuilding

Oil Pipelines

Industrial Construction

Boiler Manufacturing

| Model | SISCO-WG-FS |

| Material | Stainless Steel |

| Measuring Range | 0–20mm |

| Gauge Thickness | 2mm |

| Accuracy | ±0.3mm |

| Scale Process | Laser-engraved markings |

| Weight | 0.17kg |

| Measurement Functions | Designed to measure groove angles, weld bead width, weld height, and welding gaps on welded components. |

| Applications | Ideal for inspecting weld quality in high-requirement industries such as boilers, pressure vessels, and other critical structural components. |

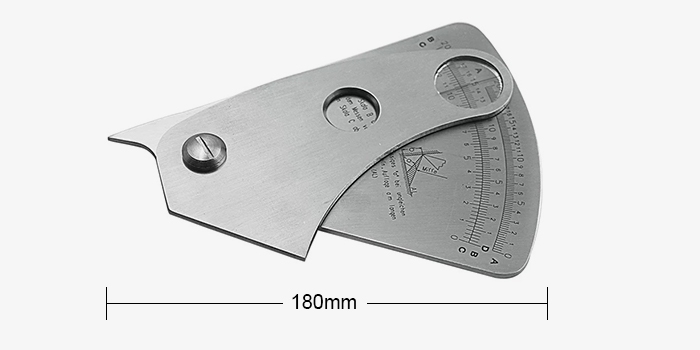

Dimensions (mm)

Q1: What materials is the fan-shaped weld gauge made from?

A1: SISCO's fan-shaped weld gauge is crafted from high-quality, industrial-grade stainless steel, known for its superior hardness, corrosion resistance, and structural integrity. Thanks to its robust build and precision laser-engraved scales, the welding gauge is highly resistant to wear and deformation even under frequent, intensive use. This makes it an ideal welding inspection tool in demanding environments such as shipbuilding, boiler fabrication, bridge construction, and pressure vessel welding.

Q2: What welding parameters can this gauge measure?

A2: This versatile welding gauge is designed to measure multiple critical welding dimensions with high accuracy. It can assess groove angles, weld bead height, weld seam width, and welding root gap—parameters essential for ensuring the structural strength and compliance of welded joints. Whether you're performing pre-welding setup verification or post-welding quality checks, this fan-type weld gauge provides reliable and repeatable measurements across a wide range of applications.

Q3: Is the fan-shaped welding gauge easy to carry and use on-site?

A3: Absolutely. Weighing just 0.17 kg and featuring a compact, foldable fan-shaped structure, the weld gauge is exceptionally portable. Its ergonomic design includes rounded edges and a comfortable grip zone, allowing for safe, fatigue-free operation during extended work sessions. The slim profile and sturdy construction mean it fits easily into tool belts, welding pouches, or protective cases, making it a perfect companion for on-site weld inspections in field and workshop environments alike.

Tips: What’s the best way to maintain the accuracy of a fan-shaped weld gauge?

To preserve the long-term accuracy and performance of your fan-shaped welding gauge, it’s essential to follow a few simple maintenance steps. After each use, wipe the surface with a clean, dry cloth to remove welding spatter, dust, or moisture. Store the gauge in a protective case to avoid accidental scratches or impacts, especially in toolboxes. While the stainless steel body offers excellent corrosion resistance, avoid exposing the gauge to harsh chemicals or extreme humidity for prolonged periods. A well-maintained stainless steel weld gauge not only ensures measurement reliability but also extends the tool's service life in industrial settings.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.