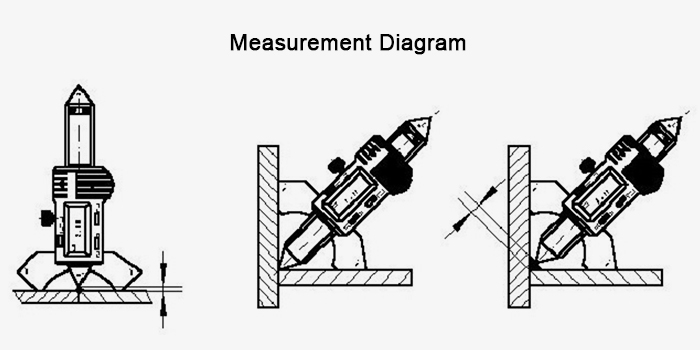

This digital weld gauge features zero-setting at any position, allowing for effortless switching between relative and absolute measurements. It also supports metric and imperial unit conversions, accommodating diverse measuring habits and global welding standards. With a compact structure, sleek appearance, and easy-to-operate design, this fillet weld gauge is well-suited for applications in machinery manufacturing, pressure vessels, structural steelwork, and other industrial settings.

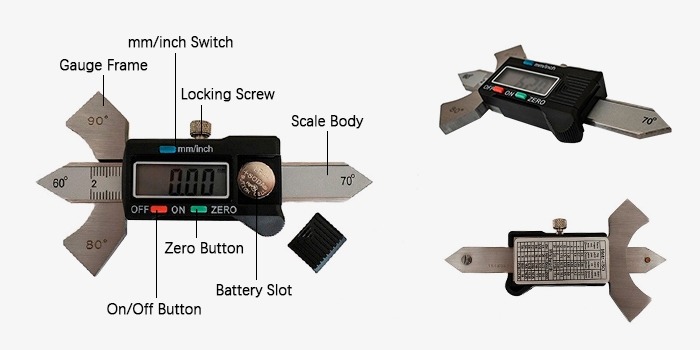

Multi-Angle Templates for Complex Welds

- Equipped with 60°, 70°, 80°, and 90° angle templates, this digital welding gauge supports accurate angle inspections across a wide variety of joint types, making it easy to work in tight or geometrically complex environments.

- The welding gauge's body is made from high-grade stainless steel with a polished surface for excellent corrosion resistance and ease of cleaning, ideal for frequent use in harsh industrial conditions.

Clear Digital Display for One-Hand Operation

- The digital welding gauge is fitted with a high-contrast LED LCD screen, providing intuitive and accurate readouts, even in low-light environments, minimizing the risk of reading errors.

- Lightweight and compact, the weld gauge fits comfortably in one hand, enabling single-handed operation without the need for additional tools, perfect for improving efficiency in daily weld inspection tasks.

Applications

Weld gauges are widely used in various industries. In boiler manufacturing, they measure weld reinforcement, width, misalignment, and undercut depth to meet pressure part standards. In shipbuilding, they check fillet weld size, leg height, and assembly gaps to ensure hull strength. In oil pipelines, welding gauges assess groove angles and gap sizes to prevent welding defects and leaks. In industrial construction—such as bridges and pressure vessels—they provide accurate weld dimension data for process evaluation and quality control.

Shipbuilding

Oil Pipelines

Industrial Construction

Boiler Manufacturing

| Model | SISCO-WG-SXG-20 |

| Measuring Range | 0-20mm (0-0.8'') |

| Resolution | 0.01mm |

| Indication Error | ±0.03mm / ±0.001'' |

| Material | Stainless Steel |

| Power Supply | 1.5V button cell battery |

| Operating Temperature | 0~40℃ |

| Storage Temperature | -10℃~60℃ |

| Operating Humidity | ≤80%RH |

| Net Weight | 200g |

Details

Q1: What types of weld measurements can this digital weld gauge perform?

A1: This high-precision digital welding gauge is designed to measure the height of both butt and fillet welds. It is equipped with four angle templates—60°, 70°, 80°, and 90°—making it suitable for inspecting a wide variety of welding configurations. It’s an ideal weld measurement tool for industries such as pipeline construction, steel structures, and pressure vessel manufacturing.

Q2: Does this welding inspection gauge support metric/imperial conversion and relative/absolute measurement switching?

A2: Yes. The digital weld gauge supports instant switching between metric (mm) and imperial (inch) units. It also allows for zero setting at any position, enabling both relative and absolute measurements. These features offer excellent versatility, especially for users working on international welding projects.

Q3: Is the LED display readable in different lighting conditions?

A3: Absolutely. This digital weld gauge features a high-contrast LED display, ensuring clear and accurate readings even in low-light or high-glare environments. It minimizes reading errors and improves efficiency in demanding work conditions.

Tips: What should you pay attention to when using this digital weld gauge?

- Do not move the gauge body at speeds exceeding 1.5 m/s during measurement.

- As a precision measuring instrument, it should be protected from impacts or drops to avoid loss of accuracy.

- Keep the device clean and dry. Prevent any liquid, such as water, from seeping into the internal components, which could affect its performance.

- The surface can be wiped with anhydrous alcohol; avoid using organic solvents such as acetone.

- Do not apply voltage to the device or use an electric pen to mark it, as this may damage the internal circuitry.

- When handling the battery, avoid charging, disassembling, or short-circuiting it. If the digital display becomes unresponsive after replacing the battery, remove it and reinstall it after one minute to reset the circuit.

- If not used for an extended period, remove the battery and store it separately from the digital weld gauge.

- Do not disassemble the digital welding gauge on your own.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.